TABLE OF CONTENTS |

|

|

General Information | page | 2 |

Inventory | page | 2 |

Tools and Building Supplies | page | 2 |

Installation Applications | page | 2 |

Important Safety Information | page | 2 |

Codes | page | 3 |

Combustion and Ventilation Air | page | 3 |

Location of Fireplace | page | 4 |

Clearances | page | 5 |

Preinstallation | page | 5 |

Installation – | page | 5 |

Framing Dimensions | page | 6 |

Electrical Wiring – Optional Blower . page | 7 | |

Gas Pressure Check | page | 7 |

Finished Wall Details | page | 8 |

Installation – Surround | page | 8 |

Connecting Gas Line | page | 9 |

Log Assembly | page | 9 |

Flame Appearance | page | 9 |

Optional Equipment | page 10 | |

Forced Air Kit | page 10 | |

Cleaning and Servicing | page 12 | |

Accessories/Components | page 12 | |

Appliance Specifications | page 14 | |

Troubleshooting Guide | page 15 | |

Operating Instructions | page 16 | |

Replacement Parts List | page 18 | |

Replacement Parts | page 19 | |

GENERAL INFORMATION

The VF5000 and VF6000 Series Unvented Room Heaters covered in this manual feature ceramic fiber split logs which glow realistically when the heater is operating.

These heaters are manually controlled.

A spark ignition system (piezo) allows the heater pilot gas to be lit without the use of matches or batteries and permits operation of the heater during a power outage.

These heaters are fitted with a specially de- signed pilot (ODS) which responds to the amount of oxygen available in the room and shuts the heater off before the oxygen level drops below 18%. The pilot can be relit only when fresh air is available. Refer to the Com- bustion and Ventilation Air section.

The VF5000 and VF6000 Series Unvented Room Heaters may be built into a framed wall, or installed in an optional oak surround.

This heater has been tested to the standards of ANSI Z21.11.2 unvented heaters.

Do not install these unvented room heaters in a bedroom or bathroom as all units exceed maximum allowable BTU/Hr input of 10,000.

Inventory

Unvented Gas Fireplace Gas connection fittings

Installation and Operating Instructions

Tools and Building Supplies

Normally Required

Tools Should Include:

Phillips screwdriver

Hammer

Saw and/or Sabersaw

Measuring tape

Electric drill and bits

Pliers

Square

Piping complying with local codes

Pipe wrench

Tee joint

Pipe compound

Building Supplies Should Include:

Framing materials Wall finishing materials

Caulking materials (noncombustible) Fireplace surround materials

Installation Applications

1.Fireplace built into a framed wall.

2.Fireplace installed with oak surround and/ or platform (Refer to the DV5/6 unfinished oak veneer surround installation instructions, P/N 903593).

Check the inventory list to be sure that you have all the necessary parts in usable condition. Also check for concealed damage.

IMPORTANT SAFETY INFORMATION

INSTALLER: PLEASE LEAVE THESE INSTRUC- TIONS WITH THE OWNER.

OWNER: PLEASE RETAIN THESE INSTRUC- TION FOR FUTURE REFERENCE.

IMPORTANT: BEFORE STARTING YOUR HEATER INSTALLATION, READ THESE INSTAL- LATION INSTRUCTIONS CAREFULLY TO BE SURE YOU UNDERSTAND THEM COMPLETELY AND IN ENTIRETY. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD CAUSE A HEATER MALFUNCTION RESULTING IN SERI- OUS INJURY AND/OR PROPERTY DAMAGE.

2

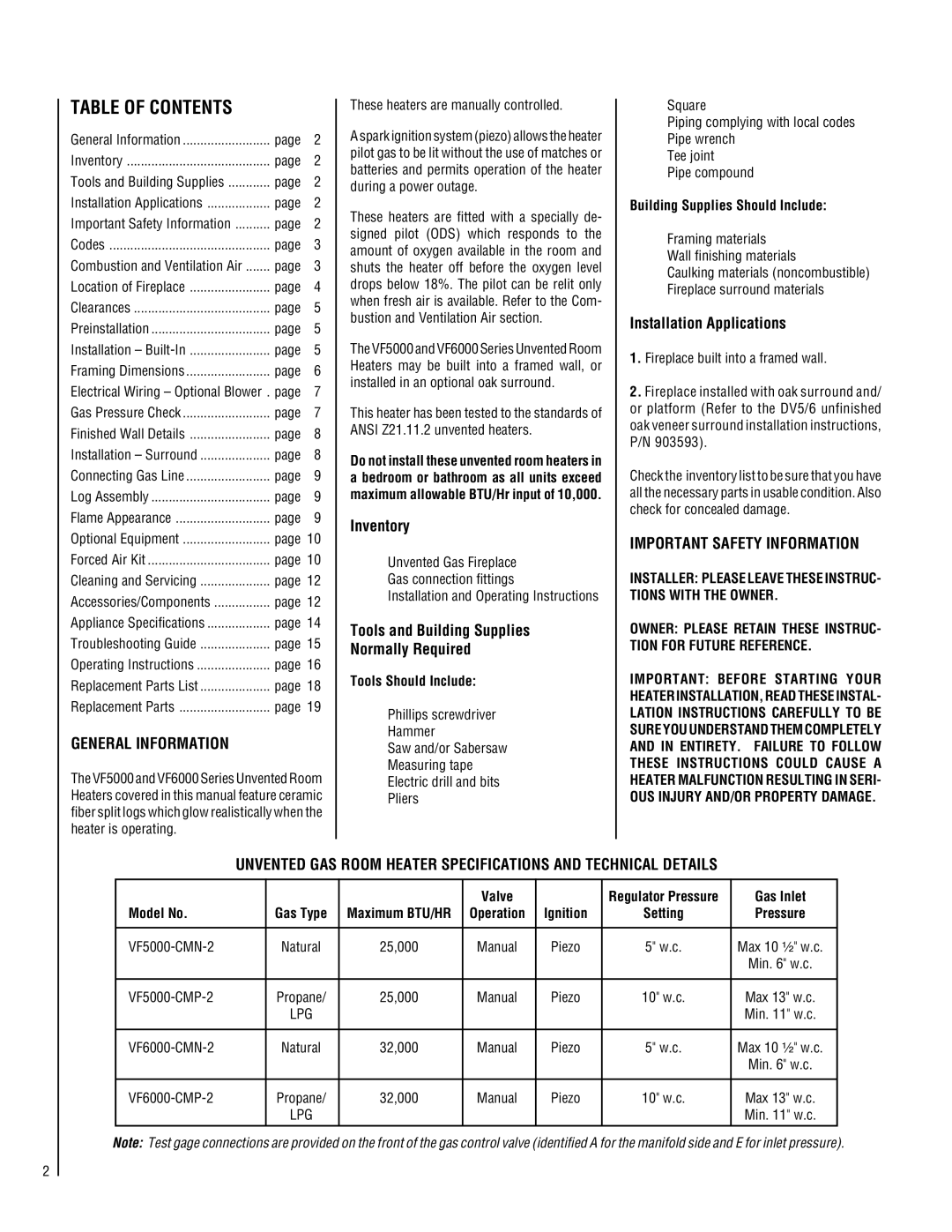

UNVENTED GAS ROOM HEATER SPECIFICATIONS AND TECHNICAL DETAILS

|

|

| Valve |

| Regulator Pressure | Gas Inlet |

Model No. | Gas Type | Maximum BTU/HR | Operation | Ignition | Setting | Pressure |

|

|

|

|

|

|

|

Natural | 25,000 | Manual | Piezo | 5" w.c. | Max 10 ¹⁄₂" w.c. | |

|

|

|

|

|

| Min. 6" w.c. |

|

|

|

|

|

|

|

Propane/ | 25,000 | Manual | Piezo | 10" w.c. | Max 13" w.c. | |

| LPG |

|

|

|

| Min. 11" w.c. |

|

|

|

|

|

|

|

Natural | 32,000 | Manual | Piezo | 5" w.c. | Max 10 ¹⁄₂" w.c. | |

|

|

|

|

|

| Min. 6" w.c. |

|

|

|

|

|

|

|

Propane/ | 32,000 | Manual | Piezo | 10" w.c. | Max 13" w.c. | |

| LPG |

|

|

|

| Min. 11" w.c. |

Note: Test gage connections are provided on the front of the gas control valve (identified A for the manifold side and E for inlet pressure).