EM1-33035, B-570-QQ SERIES, EM1-33035E specifications

The Toshiba EM1-33035E, part of the B-570-QQ Series, stands out as a versatile solution for various printing applications characterized by its reliability and cutting-edge technology. This model is designed for users who demand high-quality prints and operational efficiency, making it suitable for a diverse range of environments from industrial to commercial settings.One of the main features of the EM1-33035E is its advanced thermal transfer printing technology, allowing for crisp and durable output. The printer is capable of producing high-resolution labels, tags, and barcodes with exceptional clarity, ensuring that printed materials meet the strictest standards of legibility and quality. The use of thermal transfer ribbons contributes to the longevity and resilience of the prints, making them ideal for applications requiring exposure to various environmental factors.

The B-570-QQ Series, which includes the EM1-33035E, emphasizes user-friendliness and ease of integration. Featuring a compact design, it is suitable for limited workspace environments while still offering substantial functionality. The printer's intuitive control panel and software support allow users to operate efficiently without extensive training, reducing setup time and increasing productivity.

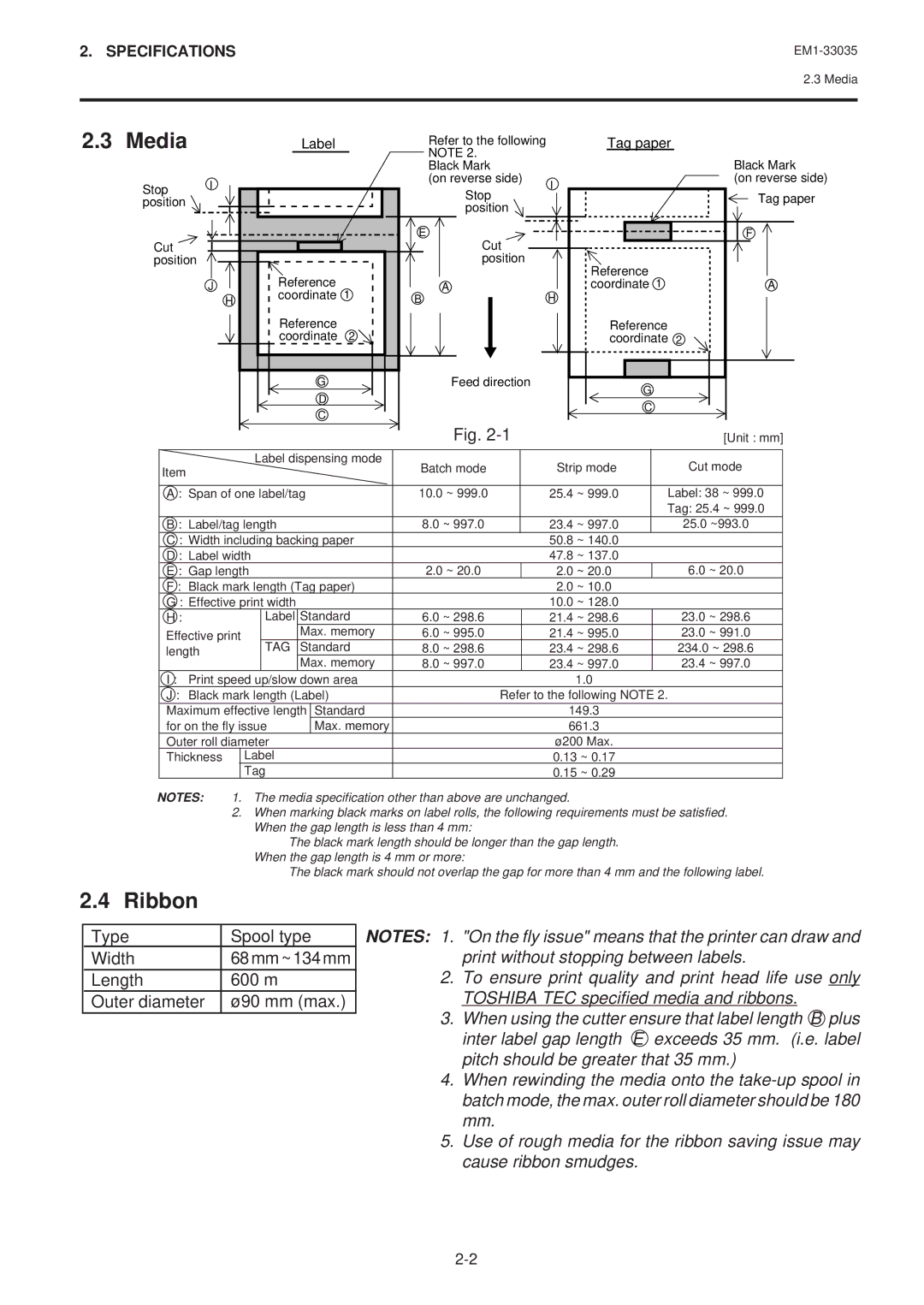

Furthermore, the EM1-33035E supports a wide range of media types and sizes, accommodating diverse printing needs. This adaptability makes it an excellent choice for industries such as logistics, retail, and manufacturing where labeling requirements can vary widely. The printer can handle different label materials, including synthetic options, ensuring compatibility with various applications.

Durability is another key characteristic of the EM1-33035E. Built to withstand the rigors of continuous operation, it features robust components designed for longevity and minimal maintenance. The printer’s energy-efficient operation not only helps in reducing operational costs but also minimizes its environmental footprint, aligning with modern sustainability goals.

In summary, the Toshiba EM1-33035E from the B-570-QQ Series is a high-performance thermal transfer printer that excels in quality, adaptability, and efficiency. Its impressive features cater to a broad range of industries, making it a dependable choice for professionals seeking an effective printing solution. Whether for high-volume tasks or specialized applications, the EM1-33035E demonstrates Toshiba's commitment to innovation and excellence in printing technology.