Section 4: Operation

![]() WARNING

WARNING

The HIGH speed belt range position combined with a FAST wheel speed setting propels the tiller at the fastest pace. Reduce the engine throttle speed when starting out to help avoid personal injury or property damage if using this speed combination.

3. Kneel on left side of tiller. To create belt slack, reach over to right side of the pulleys and push in at the center of the belt with a finger. At the same time, use your left hand to work the belt

Figure 4-10: Low range to high range. Shows moving belt from lower-rear groove onto lower-front groove.

4.Go to the other side of the tiller to finish seating the belt onto the pulley groove.

5. Working from the left side of the tiller, work the belt as much as possible onto the

6.Finish seating the belt from the right side of the tiller.

IMPORTANT: Proper belt tension is important for good performance. See Section 5, Drive Belt Maintenance for information on belt maintenance schedule and procedures.

NOTE: If extra belt slack is needed to move the belt, just raise the Wheels/Tines/ PTO Drive Lever up into REVERSE. This lowers the engine pulley, and creates more slack.

Figure 4-11: Low range to high range. Shows moving belt from top- rear groove onto top-front groove.

7.Check both sides of the high range pulley grooves to verify that the belt is properly seated.

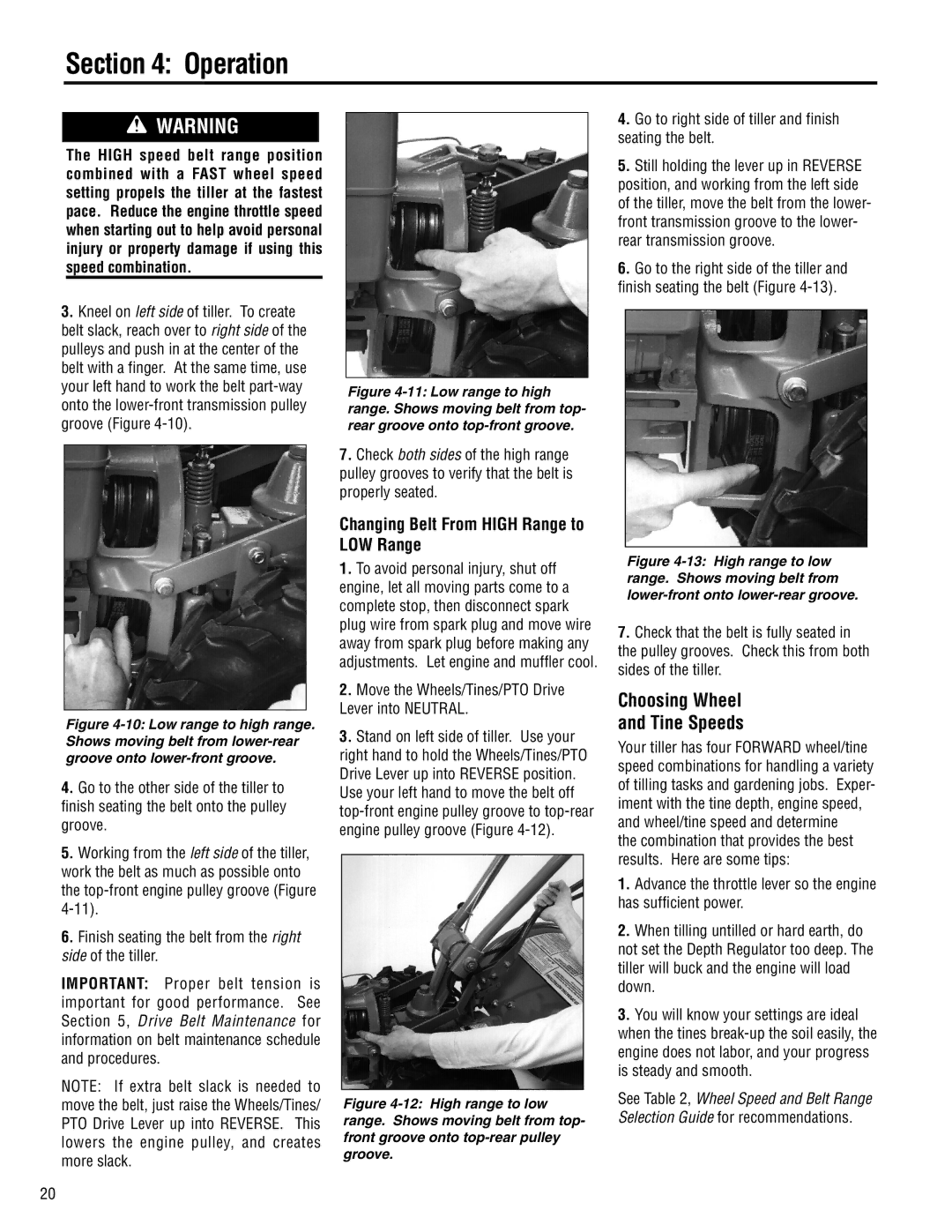

Changing Belt From HIGH Range to LOW Range

1. To avoid personal injury, shut off engine, let all moving parts come to a complete stop, then disconnect spark plug wire from spark plug and move wire away from spark plug before making any adjustments. Let engine and muffler cool.

2. Move the Wheels/Tines/PTO Drive Lever into NEUTRAL.

3. Stand on left side of tiller. Use your right hand to hold the Wheels/Tines/PTO Drive Lever up into REVERSE position. Use your left hand to move the belt off

Figure 4-12: High range to low range. Shows moving belt from top- front groove onto top-rear pulley groove.

4. Go to right side of tiller and finish seating the belt.

5. Still holding the lever up in REVERSE position, and working from the left side of the tiller, move the belt from the lower- front transmission groove to the lower- rear transmission groove.

6. Go to the right side of the tiller and finish seating the belt (Figure

Figure 4-13: High range to low range. Shows moving belt from lower-front onto lower-rear groove.

7. Check that the belt is fully seated in the pulley grooves. Check this from both sides of the tiller.

Choosing Wheel

and Tine Speeds

Your tiller has four FORWARD wheel/tine speed combinations for handling a variety of tilling tasks and gardening jobs. Exper- iment with the tine depth, engine speed, and wheel/tine speed and determine

the combination that provides the best results. Here are some tips:

1. Advance the throttle lever so the engine has sufficient power.

2. When tilling untilled or hard earth, do not set the Depth Regulator too deep. The tiller will buck and the engine will load down.

3. You will know your settings are ideal when the tines

See Table 2, Wheel Speed and Belt Range Selection Guide for recommendations.

20