Section 5: Maintenance

WARNING

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

Figure 5-7: Remove oil level check plug. Gear oil should seep out if the level is sufficient.

3.If the oil level is correct, oil will seep out of the check hole (allow extra time in cold weather). If it does, the level is fine and you should replace the check plug. If no oil seeps out, see Adding or Changing Gear Oil.

Checking the Tine

Attachment Oil Level

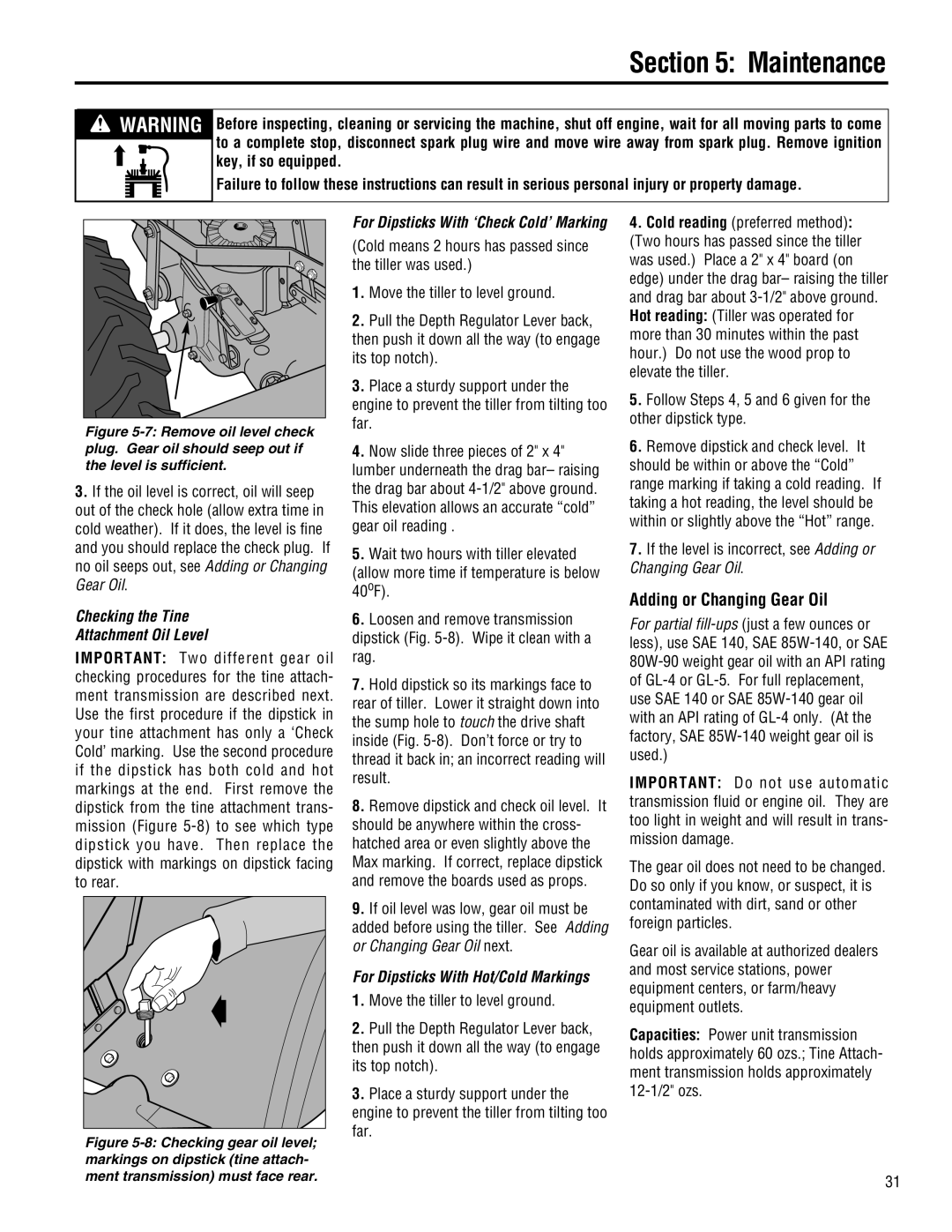

IMPORTANT: Two different gear oil checking procedures for the tine attach- ment transmission are described next. Use the first procedure if the dipstick in your tine attachment has only a ‘Check Cold’ marking. Use the second procedure if the dipstick has both cold and hot markings at the end. First remove the dipstick from the tine attachment trans- mission (Figure

➧

For Dipsticks With ‘Check Cold’ Marking

(Cold means 2 hours has passed since the tiller was used.)

1.Move the tiller to level ground.

2.Pull the Depth Regulator Lever back, then push it down all the way (to engage its top notch).

3.Place a sturdy support under the engine to prevent the tiller from tilting too far.

4.Now slide three pieces of 2" x 4" lumber underneath the drag bar– raising the drag bar about

5.Wait two hours with tiller elevated

(allow more time if temperature is below 40oF).

6.Loosen and remove transmission dipstick (Fig.

7.Hold dipstick so its markings face to rear of tiller. Lower it straight down into the sump hole to touch the drive shaft inside (Fig.

8.Remove dipstick and check oil level. It should be anywhere within the cross- hatched area or even slightly above the Max marking. If correct, replace dipstick and remove the boards used as props.

9.If oil level was low, gear oil must be added before using the tiller. See Adding or Changing Gear Oil next.

For Dipsticks With Hot/Cold Markings

1.Move the tiller to level ground.

2.Pull the Depth Regulator Lever back, then push it down all the way (to engage its top notch).

3.Place a sturdy support under the engine to prevent the tiller from tilting too far.

4.Cold reading (preferred method): (Two hours has passed since the tiller was used.) Place a 2" x 4" board (on edge) under the drag bar– raising the tiller and drag bar about

5.Follow Steps 4, 5 and 6 given for the other dipstick type.

6.Remove dipstick and check level. It should be within or above the “Cold” range marking if taking a cold reading. If taking a hot reading, the level should be within or slightly above the “Hot” range.

7.If the level is incorrect, see Adding or Changing Gear Oil.

Adding or Changing Gear Oil

For partial

IMPORTANT: Do not use automatic transmission fluid or engine oil. They are too light in weight and will result in trans- mission damage.

The gear oil does not need to be changed. Do so only if you know, or suspect, it is contaminated with dirt, sand or other foreign particles.

Gear oil is available at authorized dealers and most service stations, power equipment centers, or farm/heavy equipment outlets.

Capacities: Power unit transmission holds approximately 60 ozs.; Tine Attach- ment transmission holds approximately

Figure |

|

markings on dipstick (tine attach- |

|

ment transmission) must face rear. | 31 |

|