Appendix A: Troubleshooting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PROBLEM |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CHECK OR TEST |

|

|

| Engine |

|

| Engine shuts off when |

|

|

| Engine does not shut off |

| |

| (Check or test in sequence shown |

|

|

| won’t start |

|

| Wheels/Tines/PTO Drive |

|

|

| when Forward Interlock |

| |

|

|

|

|

|

|

| Lever is shifted into |

|

|

| Levers are released while |

| ||

| until problem is resolved.) |

|

|

|

|

|

| FORWARD |

|

|

| Wheels/Tines/PTO Drive |

| |

|

|

|

|

|

|

|

|

|

|

|

| Lever is in FORWARD |

| |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Throttle Lever in START position |

|

|

| X |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Wheels/Tines/PTO Drive Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

| in NEUTRAL position |

|

|

| X |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Forward Interlock Wire Harness |

|

|

|

|

|

|

|

|

|

|

|

|

|

| connector securely mated |

|

|

|

|

|

| X |

|

| X | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Forward Interlock Levers not being |

|

|

|

|

|

|

|

|

|

|

|

|

|

| squeezed prior to shifting Wheels/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Tines/PTO Drive Lever to |

|

|

|

|

|

| X |

|

|

|

|

| |

| FORWARD position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Visually inspect for bare, broken |

|

|

|

|

|

|

|

|

|

|

|

|

|

| or disconnected wires |

|

|

| X |

|

|

|

|

| X | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check handlebar wire harness |

|

|

| X |

|

|

|

|

| X | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check transmission wire harness |

|

|

| X |

|

|

|

|

| X | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Troubleshooting Procedures

1Wheels/Tines/PTO Drive Lever: A. Lever does not stay in FORWARD–

• Drive belt may be too tight. Raise belt adjustment block a little (Sect. 5).

• Clutch pawl spring at end of lever may be overstretched. Install new spring.

B.Lever hard to shift into REVERSE–

• Check reverse disc for wear (Sect. 5).

• Check adjustment of reverse disc and/or reverse spring and plunger assy. (Sect. 5).

• Clean and

C.Tiller stays in REVERSE when lever is released–

• Lubricate motor mount bars, belt adjust- ment block and linkages on lever (Sect. 5).

• Check adjustment of reverse spring and plunger (Sect. 5). If problem persists, contact Technical Service Department.

D.Lever sticks in FORWARD–

•Lubricate motor mount bars, belt adjust- ment block, and linkages on lever (Sect. 5). If problem continues, contact the Technical Service Department.

E. Lever hard to shift into FORWARD–

•Follow advice for Problem

2 Wheel Speed Lever:

A.Lever hard to shift, or sticks in FAST or SLOW wheel gear positions–

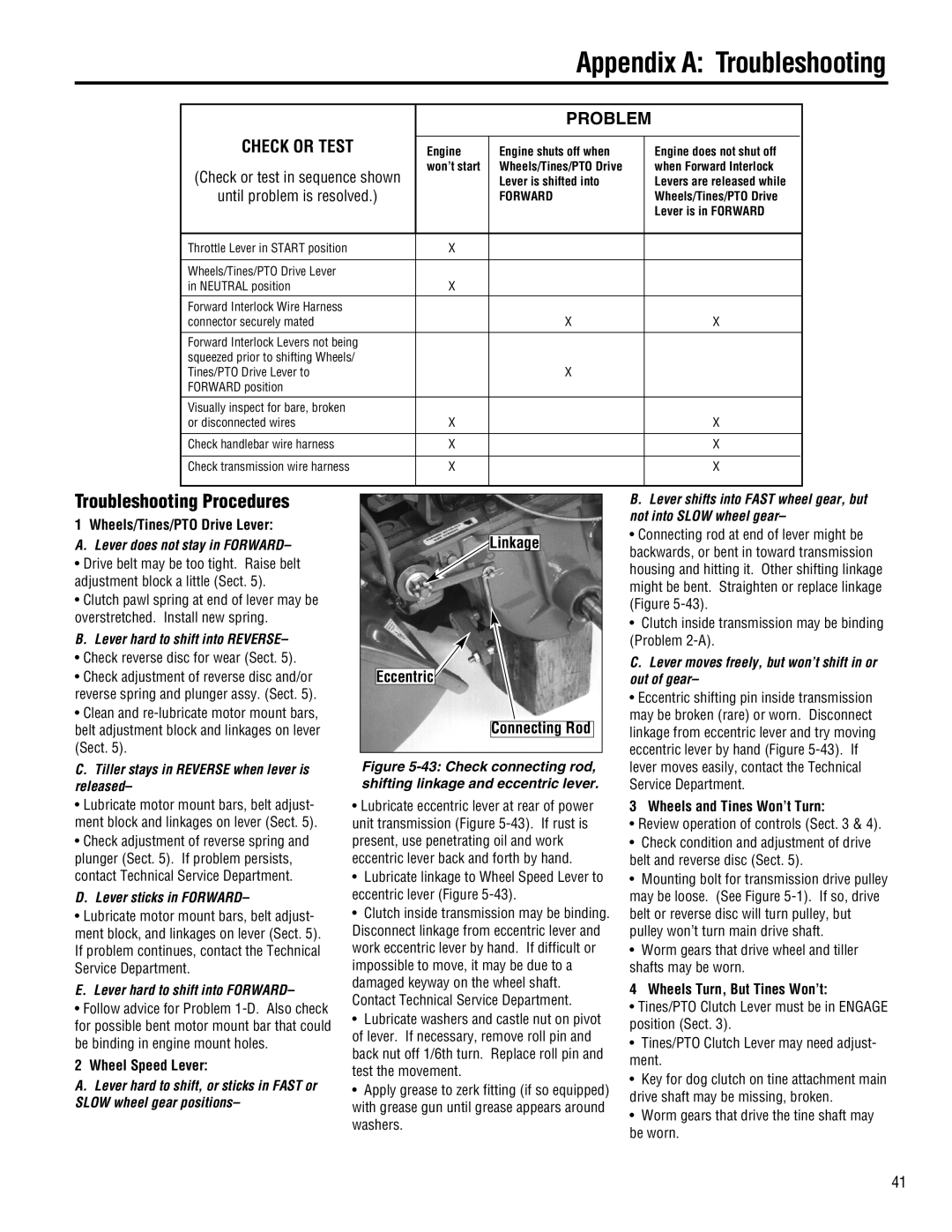

Linkage |

Eccentric |

Connecting Rod |

Figure 5-43: Check connecting rod, shifting linkage and eccentric lever.

•Lubricate eccentric lever at rear of power unit transmission (Figure

•Lubricate linkage to Wheel Speed Lever to eccentric lever (Figure

•Clutch inside transmission may be binding. Disconnect linkage from eccentric lever and work eccentric lever by hand. If difficult or impossible to move, it may be due to a damaged keyway on the wheel shaft. Contact Technical Service Department.

•Lubricate washers and castle nut on pivot of lever. If necessary, remove roll pin and back nut off 1/6th turn. Replace roll pin and test the movement.

•Apply grease to zerk fitting (if so equipped) with grease gun until grease appears around washers.

B.Lever shifts into FAST wheel gear, but not into SLOW wheel gear–

• Connecting rod at end of lever might be backwards, or bent in toward transmission housing and hitting it. Other shifting linkage might be bent. Straighten or replace linkage (Figure

• Clutch inside transmission may be binding (Problem

C.Lever moves freely, but won’t shift in or out of gear–

• Eccentric shifting pin inside transmission may be broken (rare) or worn. Disconnect linkage from eccentric lever and try moving eccentric lever by hand (Figure

3 Wheels and Tines Won’t Turn:

•Review operation of controls (Sect. 3 & 4).

•Check condition and adjustment of drive belt and reverse disc (Sect. 5).

•Mounting bolt for transmission drive pulley may be loose. (See Figure

•Worm gears that drive wheel and tiller shafts may be worn.

4 Wheels Turn, But Tines Won’t:

•Tines/PTO Clutch Lever must be in ENGAGE position (Sect. 3).

•Tines/PTO Clutch Lever may need adjust- ment.

•Key for dog clutch on tine attachment main drive shaft may be missing, broken.

•Worm gears that drive the tine shaft may be worn.

41