4.13 WASHING THE SPRAYER

Thoroughly wash the machine after each treatment pumping clean water through the circuit and clean the suction and delivery filters.

Warning: Dirty equipment is very dangerous for the people and environment. Discharging the residues of washing in the environment without taking precautions is forbidden as this pollutes watercourses. Distribute the residues on the treated field.

WARNING: The tank washing is controlled by tap N. 1, premix N. 2 and stirrer N. 3.

4.13.1CIRCUIT WASHER AND TANK WASHER

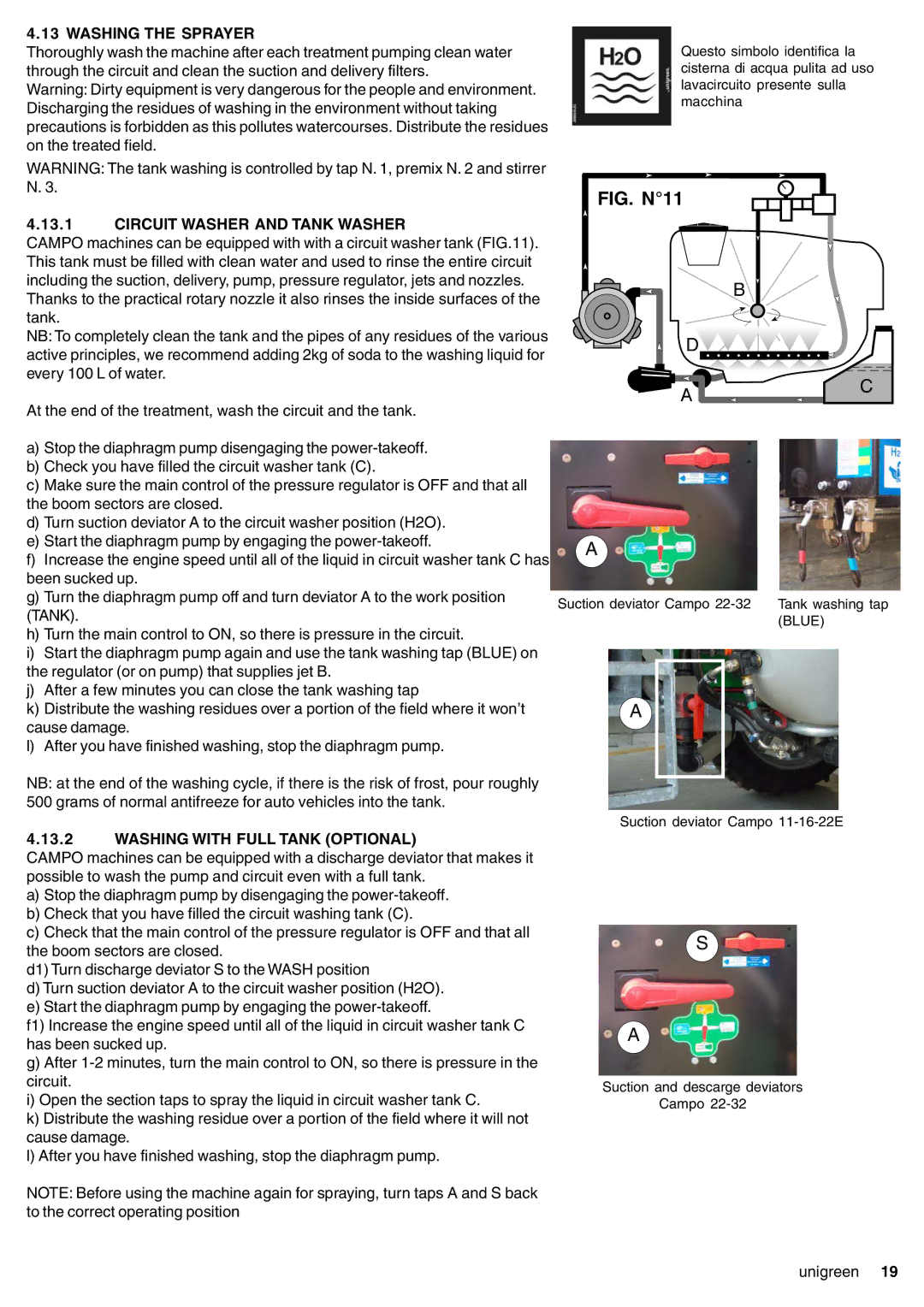

CAMPO machines can be equipped with with a circuit washer tank (FIG.11). This tank must be filled with clean water and used to rinse the entire circuit including the suction, delivery, pump, pressure regulator, jets and nozzles. Thanks to the practical rotary nozzle it also rinses the inside surfaces of the tank.

NB: To completely clean the tank and the pipes of any residues of the various active principles, we recommend adding 2kg of soda to the washing liquid for every 100 L of water.

At the end of the treatment, wash the circuit and the tank.

Questo simbolo identifica la cisterna di acqua pulita ad uso lavacircuito presente sulla macchina

FIG. N°11

| B |

D |

|

A | C |

|

a)Stop the diaphragm pump disengaging the

b)Check you have filled the circuit washer tank (C).

c)Make sure the main control of the pressure regulator is OFF and that all the boom sectors are closed.

d)Turn suction deviator A to the circuit washer position (H2O).

e)Start the diaphragm pump by engaging the

f)Increase the engine speed until all of the liquid in circuit washer tank C has been sucked up.

g)Turn the diaphragm pump off and turn deviator A to the work position (TANK).

h)Turn the main control to ON, so there is pressure in the circuit.

i)Start the diaphragm pump again and use the tank washing tap (BLUE) on the regulator (or on pump) that supplies jet B.

j)After a few minutes you can close the tank washing tap

k)Distribute the washing residues over a portion of the field where it won’t cause damage.

l)After you have finished washing, stop the diaphragm pump.

NB: at the end of the washing cycle, if there is the risk of frost, pour roughly 500 grams of normal antifreeze for auto vehicles into the tank.

A

Suction deviator Campo | Tank washing tap |

| (BLUE) |

A

Suction deviator Campo

4.13.2WASHING WITH FULL TANK (OPTIONAL)

CAMPO machines can be equipped with a discharge deviator that makes it possible to wash the pump and circuit even with a full tank.

a)Stop the diaphragm pump by disengaging the

b)Check that you have filled the circuit washing tank (C).

c)Check that the main control of the pressure regulator is OFF and that all the boom sectors are closed.

d1) Turn discharge deviator S to the WASH position

d)Turn suction deviator A to the circuit washer position (H2O).

e)Start the diaphragm pump by engaging the

f1) Increase the engine speed until all of the liquid in circuit washer tank C has been sucked up.

g)After

i)Open the section taps to spray the liquid in circuit washer tank C.

k)Distribute the washing residue over a portion of the field where it will not cause damage.

l)After you have finished washing, stop the diaphragm pump.

NOTE: Before using the machine again for spraying, turn taps A and S back to the correct operating position

S

A

Suction and descarge deviators

Campo