4.6PUMP

When using the pump scrupulously observe the instructions in the enclosed handbook supplied by the manufacturer.

The pump can be identified by the ratings plate on the same; the main data on the pressure and delivery are easy to find on this plate.

Normally the pumps mustn’t exceed 550 RPM; a higher speed won’t improve performance but there is a risk of compromising the life and safety of the pump.

There is a safety valve on the pump, calibrated to prevent overpressure. Don’t tamper with this valve for any reason and don’t block or obstruct the pipes connected to it in any way.

4.7SUCTION FILTER

The sprayer is fitted with a suction filter with filter cartridges that have roughly a

An efficient filter lets the sprayer work properly.

You should periodically check that the filter cartridge is clean, this check should be done more often if there are impurities in the liquid.

To inspect the filter cartridge wear rubber

Don’t perform this operation with the pump running as the depression produced blocks the cover preventing the removal.

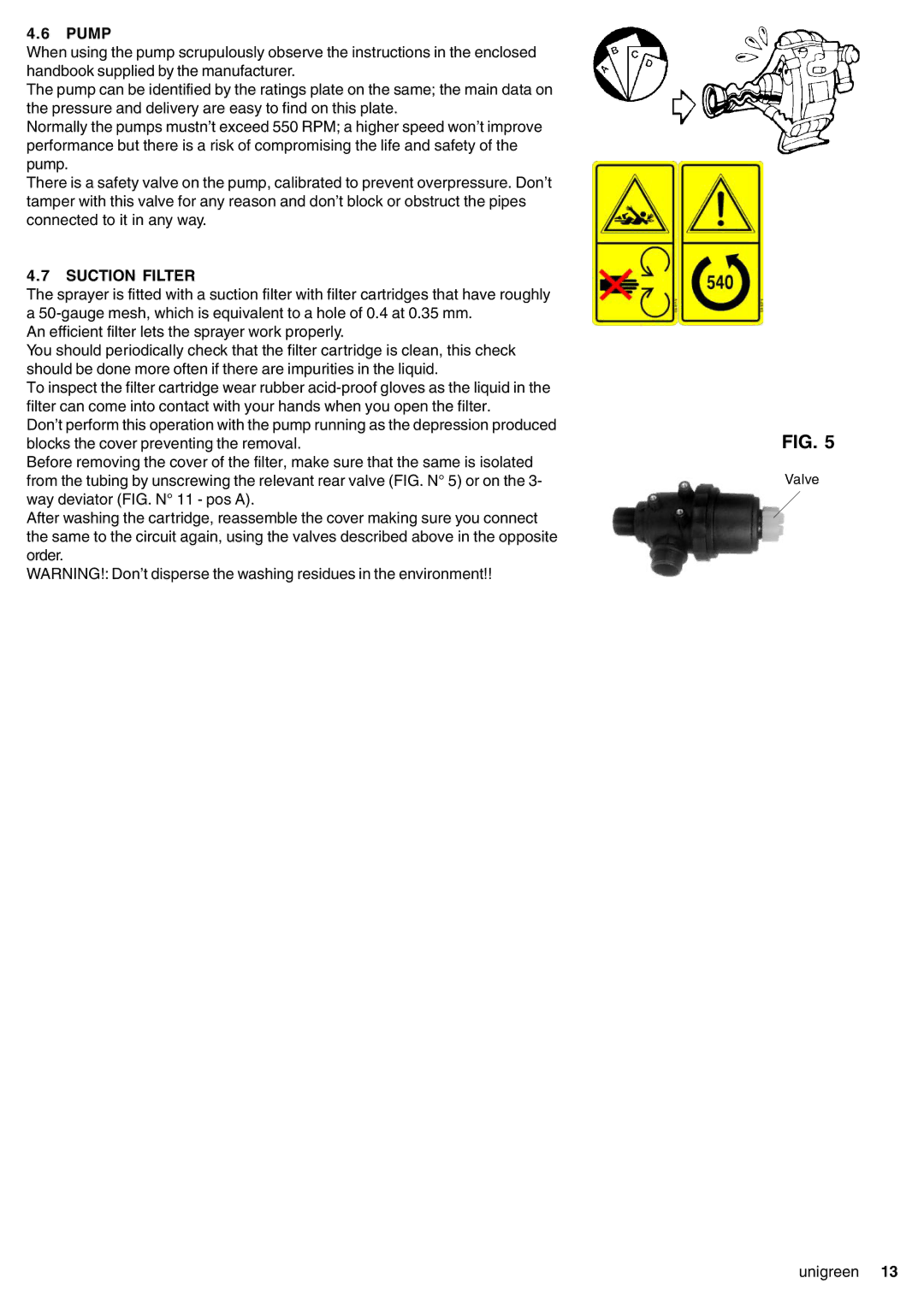

Before removing the cover of the filter, make sure that the same is isolated from the tubing by unscrewing the relevant rear valve (FIG. N° 5) or on the 3- way deviator (FIG. N° 11 - pos A).

After washing the cartridge, reassemble the cover making sure you connect the same to the circuit again, using the valves described above in the opposite order.

WARNING!: Don’t disperse the washing residues in the environment!!

FIG. 5

Valve