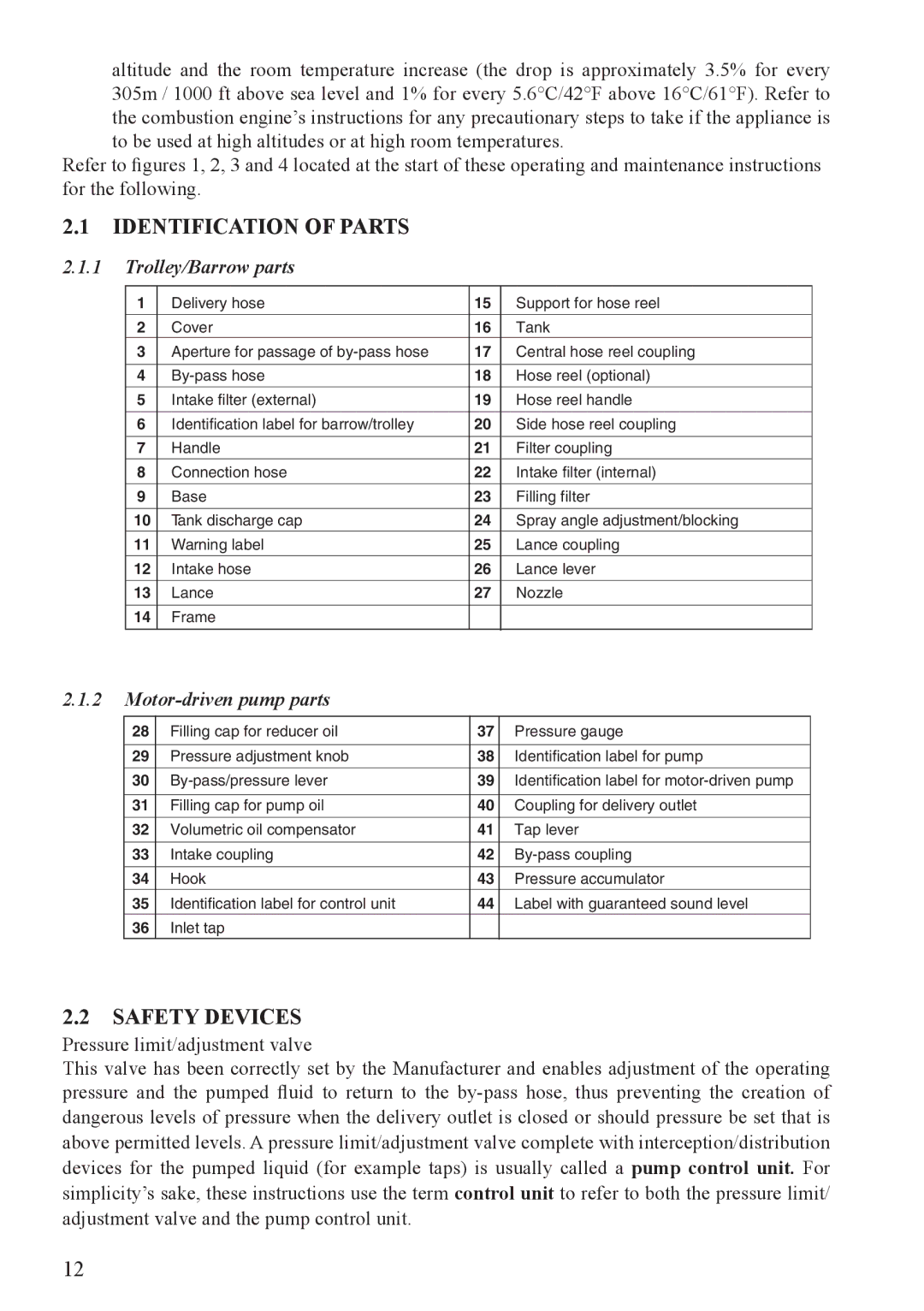

Trolleys and Barrows specifications

Unigreen Trolleys and Barrows are designed to meet the diverse needs of professionals in various industries, including gardening, agriculture, and landscaping. These innovative tools combine practicality with advanced technology, making them essential for efficient outdoor work.One of the main features of Unigreen Trolleys is their robust construction. Built from high-quality materials, these trolleys exhibit impressive durability and longevity, ensuring they can withstand the rigors of daily use. The design often includes reinforced frames and tough wheels that can handle uneven terrains, making them perfect for outdoor applications.

Another significant characteristic of Unigreen Barrows is their ergonomic design. Many models come equipped with adjustable handles that allow users to find a comfortable grip, reducing strain during prolonged use. This aspect is particularly crucial for tasks that require considerable physical effort, as it helps prevent injuries and discomfort.

Unigreen also embraces innovation through their integration of advanced technologies. Some trolleys feature smart storage solutions that maximize payload capacity while maintaining a lightweight feel. This ensures users can transport larger quantities of materials without compromising maneuverability. Additionally, several models include custom compartments for tools or supplies, aiding in organization and efficiency during tasks.

The versatility of Unigreen Trolleys and Barrows is another standout feature. They can be utilized for various purposes, whether it's transporting soil, plants, or landscaping materials. Some trolleys even offer the ability to convert into different configurations, catering to specific tasks on the go.

In terms of maintenance, Unigreen products are designed for easy cleaning and upkeep. Smooth surfaces and detachable components allow users to quickly maintain their equipment, ensuring longevity and consistent performance.

Ultimately, Unigreen Trolleys and Barrows present a compelling combination of strength, ergonomics, and versatility. Their advanced design and technology make them an excellent choice for anyone looking to enhance productivity in their outdoor work. Whether you're a professional landscaper or a gardening enthusiast, Unigreen offers a reliable solution that supports your efforts and elevates your experience in the field.