SECTION 1 OVERVIEW

INTRODUCTION

Featuring

Switches:

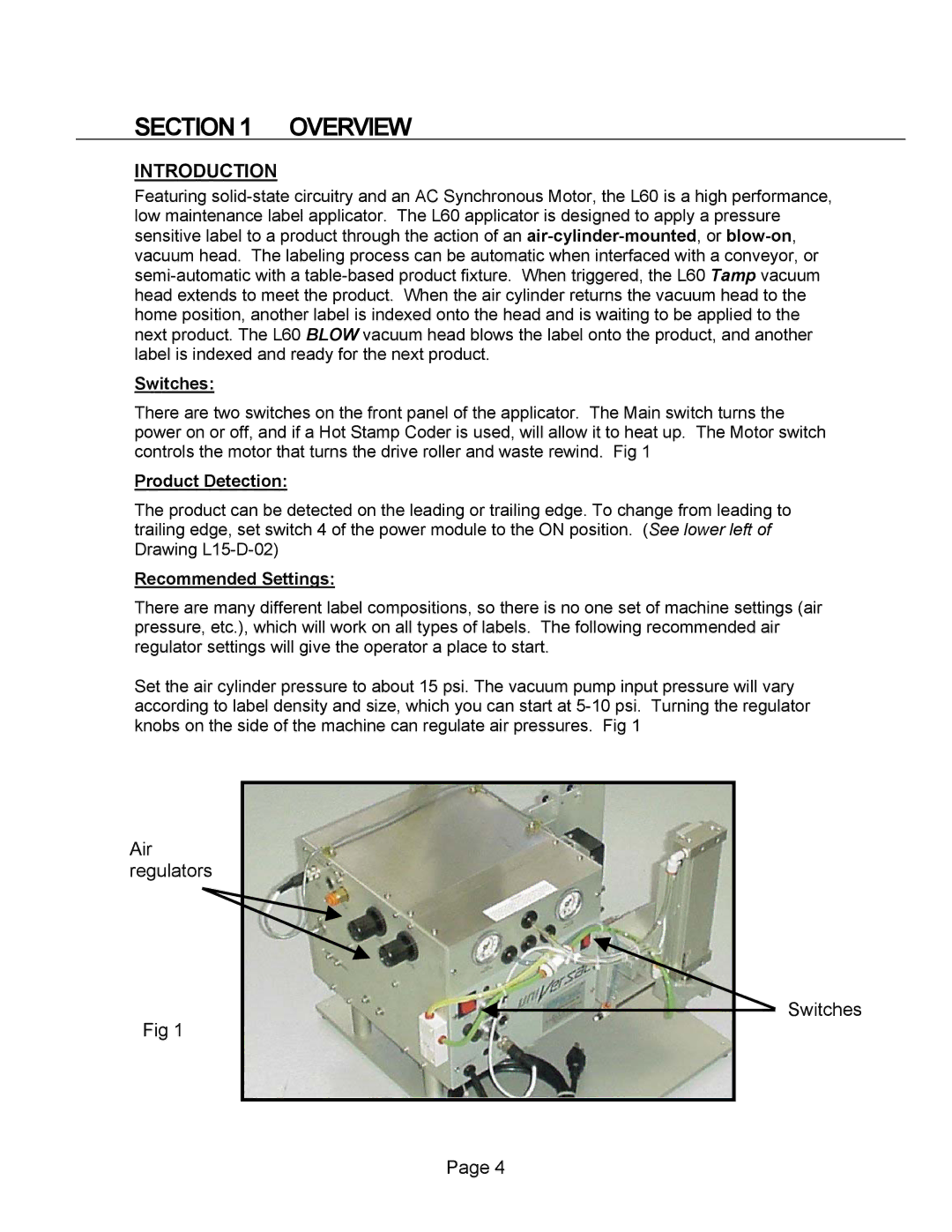

There are two switches on the front panel of the applicator. The Main switch turns the power on or off, and if a Hot Stamp Coder is used, will allow it to heat up. The Motor switch controls the motor that turns the drive roller and waste rewind. Fig 1

Product Detection:

The product can be detected on the leading or trailing edge. To change from leading to trailing edge, set switch 4 of the power module to the ON position. (See lower left of Drawing

Recommended Settings:

There are many different label compositions, so there is no one set of machine settings (air pressure, etc.), which will work on all types of labels. The following recommended air regulator settings will give the operator a place to start.

Set the air cylinder pressure to about 15 psi. The vacuum pump input pressure will vary according to label density and size, which you can start at

Air regulators

Fig 1

Switches

Page 4