INSTALLATION - CLEANING - MAINTENANCE

INSTALLATION:

The mixer can be placed directly on the floor. Foundation bolts in the floor are necessary only under special conditions, e.g. in ships.

If the

shipping pallet.

Ensure that the voltage, phase and hertz printed on the identification plate of the mixer are the same as that at the place of installation. The identification plate is located at the top of the right side of the mixer. Be sure the mixer is properly connected to the incoming power supply and the ground or earth connection is made. The arrow on the front of the planetary head (see drawing 2, page 1), indicates the direction of rotation of the planetary head. On

the connecting cable or the motor. Electrical connections must be made in accordance with local regulations.

DOUGH HOOK CLEANING:

Special care should be given to cleaning the dough hook. The Varimixer dough hook is manufactured of stainless steel and we rec- ommend that it be cleaned and sanitized in a commercial dish machine. An alternate cleaning procedure is to vigorously scrub the dough hook with a hot water and detergent solution. Use a heavy bristled brush. After cleaning, sanitize the dough hook by rinsing with a 50 ppm solution of sodium hypochlorite.

CLEANING:

The mixer should be cleaned daily or after use. Wash with a soft brush and pure water. Synthetic detergents should be used with care as they destroy the lubricants of the mixer. Washing with a hose is not recommended. Bowls and mixing tools should be washed in detergents which do not attack aluminum. Detergent suppliers will be able to recommend the right type.

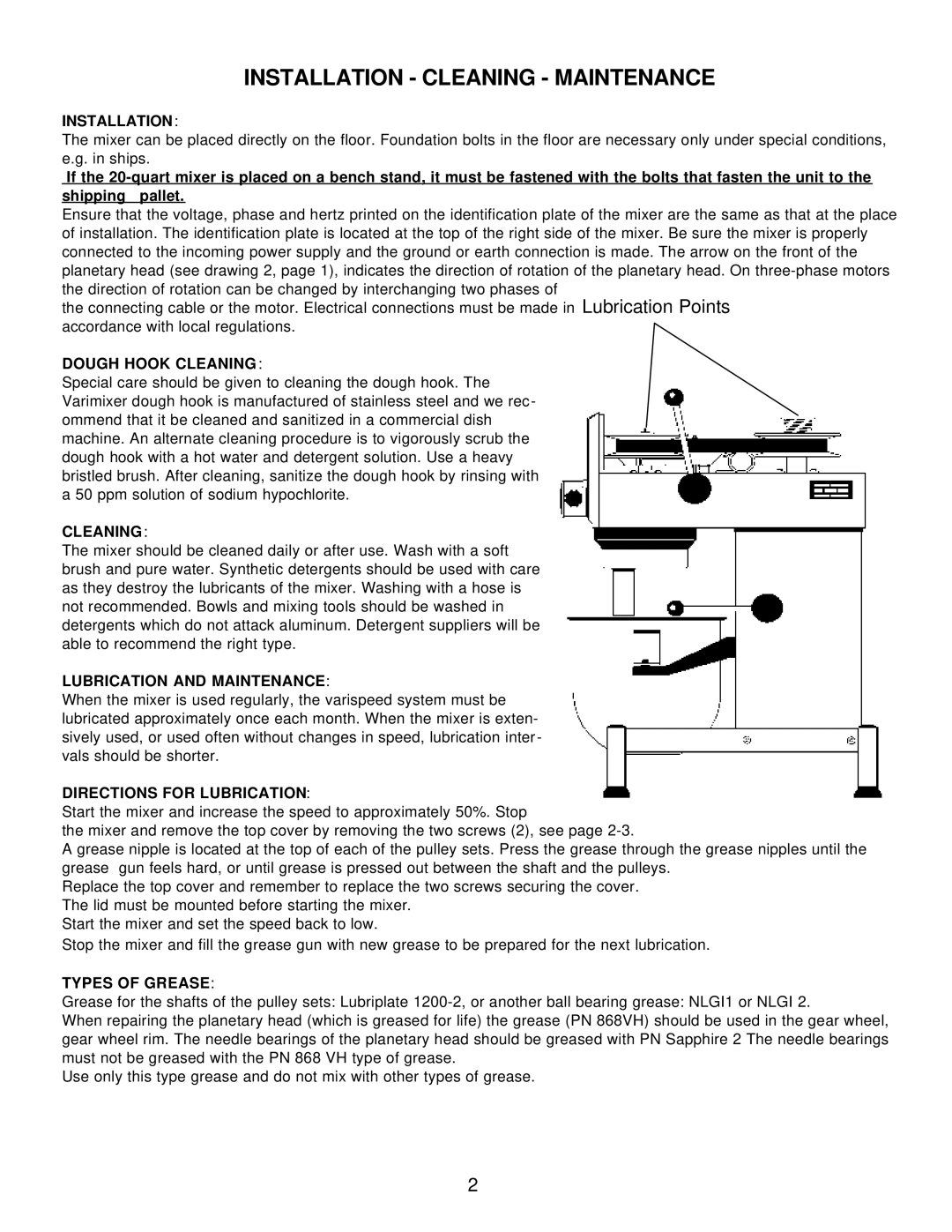

LUBRICATION AND MAINTENANCE:

When the mixer is used regularly, the varispeed system must be lubricated approximately once each month. When the mixer is exten- sively used, or used often without changes in speed, lubrication inter- vals should be shorter.

DIRECTIONS FOR LUBRICATION:

Start the mixer and increase the speed to approximately 50%. Stop

the mixer and remove the top cover by removing the two screws (2), see page

A grease nipple is located at the top of each of the pulley sets. Press the grease through the grease nipples until the grease gun feels hard, or until grease is pressed out between the shaft and the pulleys.

Replace the top cover and remember to replace the two screws securing the cover. The lid must be mounted before starting the mixer.

Start the mixer and set the speed back to low.

Stop the mixer and fill the grease gun with new grease to be prepared for the next lubrication.

TYPES OF GREASE:

Grease for the shafts of the pulley sets: Lubriplate

When repairing the planetary head (which is greased for life) the grease (PN 868VH) should be used in the gear wheel, gear wheel rim. The needle bearings of the planetary head should be greased with PN Sapphire 2 The needle bearings must not be greased with the PN 868 VH type of grease.

Use only this type grease and do not mix with other types of grease.

2