VCBV30TN, VCBV10TP - 10, VCBV20TN, VCBV10TN, VCBV20TP - 20 specifications

Vermont Casting has long been synonymous with quality and innovation in the world of wood and gas stoves. Among their impressive line-up, the VCPV30TP, VCBV10TP, VCBV20TN, VCBV10TN, and VCBV30TP models stand out for their performance and craftsmanship.The VCPV30TP is a 30,000 BTU direct vent gas stove that combines classic styling with modern technology. One of its main features is its impressive efficiency, achieving an AFUE rating that assures homeowners of reduced energy costs and environmental impact. The stove's innovative catalytic combustion system enables a cleaner burn and enhanced heat output, making it an excellent choice for both new constructions and renovations. The unit is equipped with a large viewing window, framed by cast iron that not only adds to its rustic charm but also provides excellent heat retention.

On the other hand, the VCBV10TP and VCBV20TN models offer different BTU outputs, catering to various heating needs. The VCBV10TP produces up to 10,000 BTUs, perfect for smaller spaces, while the VCBV20TN, with its 20,000 BTU output, is ideal for medium-sized areas. Both units feature user-friendly thermostatic controls that allow for precise temperature regulation, contributing to comfort and efficiency. Their cast iron construction ensures durability and heat retention, allowing users to enjoy consistent warmth over extended periods.

The VCBV10TN and VCBV30TP-30 models also share similar engineering excellence. The VCBV10TN is designed to heat efficiently while maintaining a compact profile, ideal for homes with limited space. The VCBV30TP-30, with its enhanced features, focuses not only on performance but also on aesthetics. It boasts a stunning traditional design that complements a variety of interior styles, while still packing robust heating technologies.

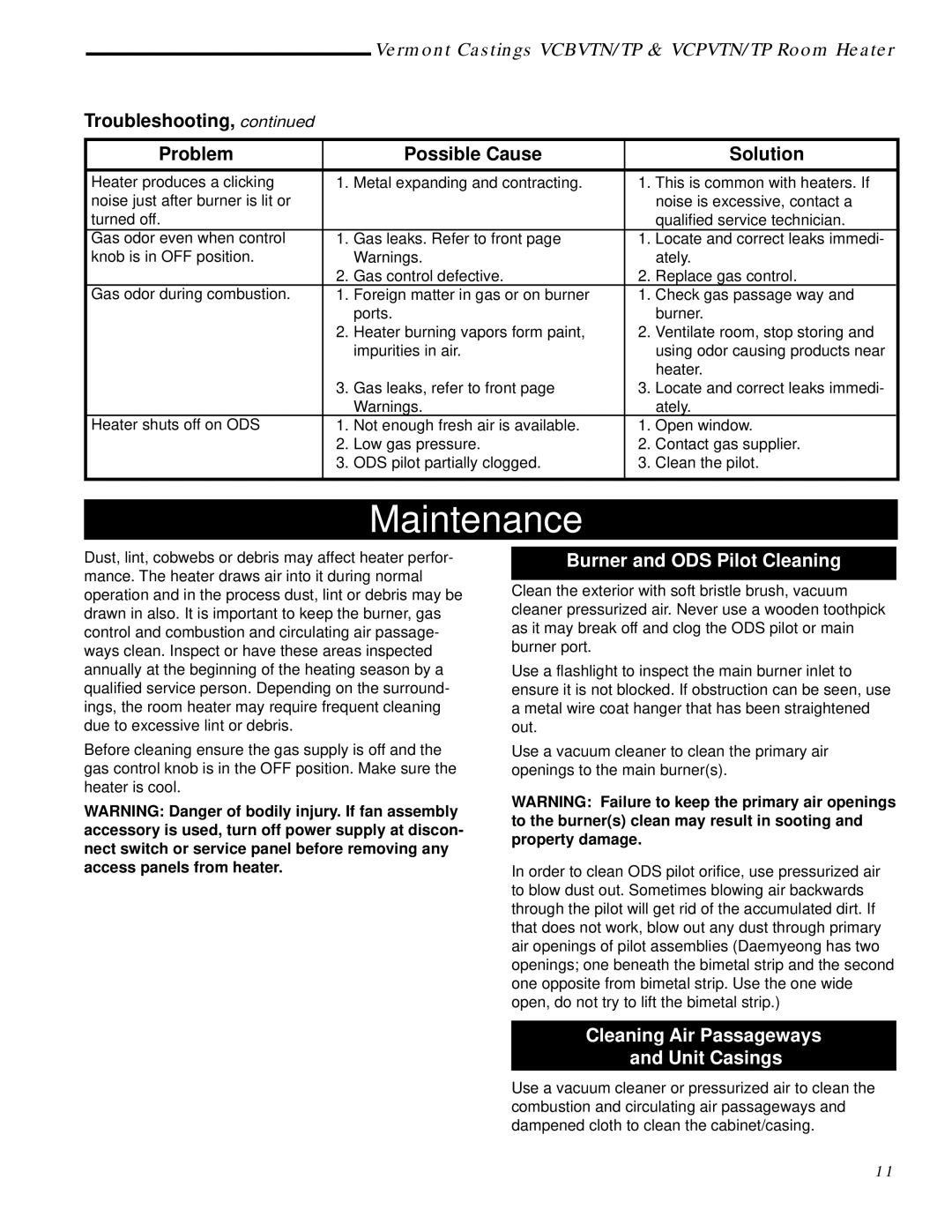

All models are designed for easy installation and maintenance, with features like clean-out access and adjustable air controls. This thoughtful engineering reflects Vermont Casting's commitment to creating products that balance performance, beauty, and practicality. In summary, the VCPV30TP, VCBV10TP, VCBV20TN, VCBV10TN, and VCBV30TP-30 embody the brand's legacy of quality and innovation, ensuring that homeowners not only stay warm but do so in style.