OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE INJECTORS

✓Remove the gratings, the burner covers and the knobs;

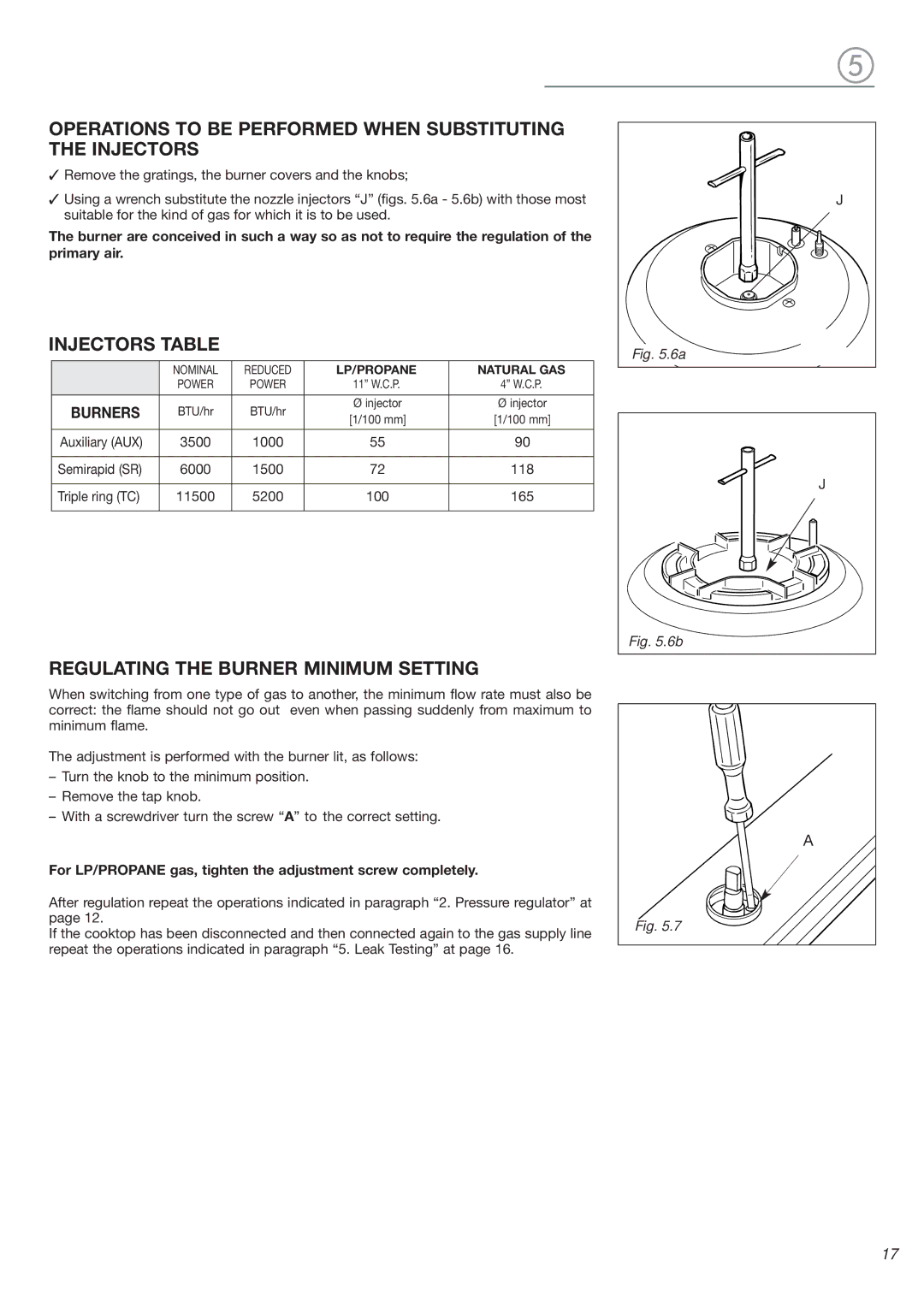

✓Using a wrench substitute the nozzle injectors “J” (figs. 5.6a - 5.6b) with those most suitable for the kind of gas for which it is to be used.

The burner are conceived in such a way so as not to require the regulation of the primary air.

INJECTORS TABLE

| NOMINAL | REDUCED | LP/PROPANE | NATURAL GAS | |

| POWER | POWER | 11” W.C.P. | 4” W.C.P. | |

BURNERS | BTU/hr | BTU/hr | Ø injector | Ø injector | |

[1/100 mm] | [1/100 mm] | ||||

|

|

| |||

Auxiliary (AUX) | 3500 | 1000 | 55 | 90 | |

Semirapid (SR) | 6000 | 1500 | 72 | 118 | |

Triple ring (TC) | 11500 | 5200 | 100 | 165 |

REGULATING THE BURNER MINIMUM SETTING

When switching from one type of gas to another, the minimum flow rate must also be correct: the flame should not go out even when passing suddenly from maximum to minimum flame.

The adjustment is performed with the burner lit, as follows:

–Turn the knob to the minimum position.

–Remove the tap knob.

–With a screwdriver turn the screw “A” to the correct setting.

For LP/PROPANE gas, tighten the adjustment screw completely.

After regulation repeat the operations indicated in paragraph “2. Pressure regulator” at page 12.

If the cooktop has been disconnected and then connected again to the gas supply line repeat the operations indicated in paragraph “5. Leak Testing” at page 16.

J

Fig. 5.6a

J

Fig. 5.6b

A |

Fig. 5.7 |

17