J150 COMPRESSOR

Installation and Operation

Manual

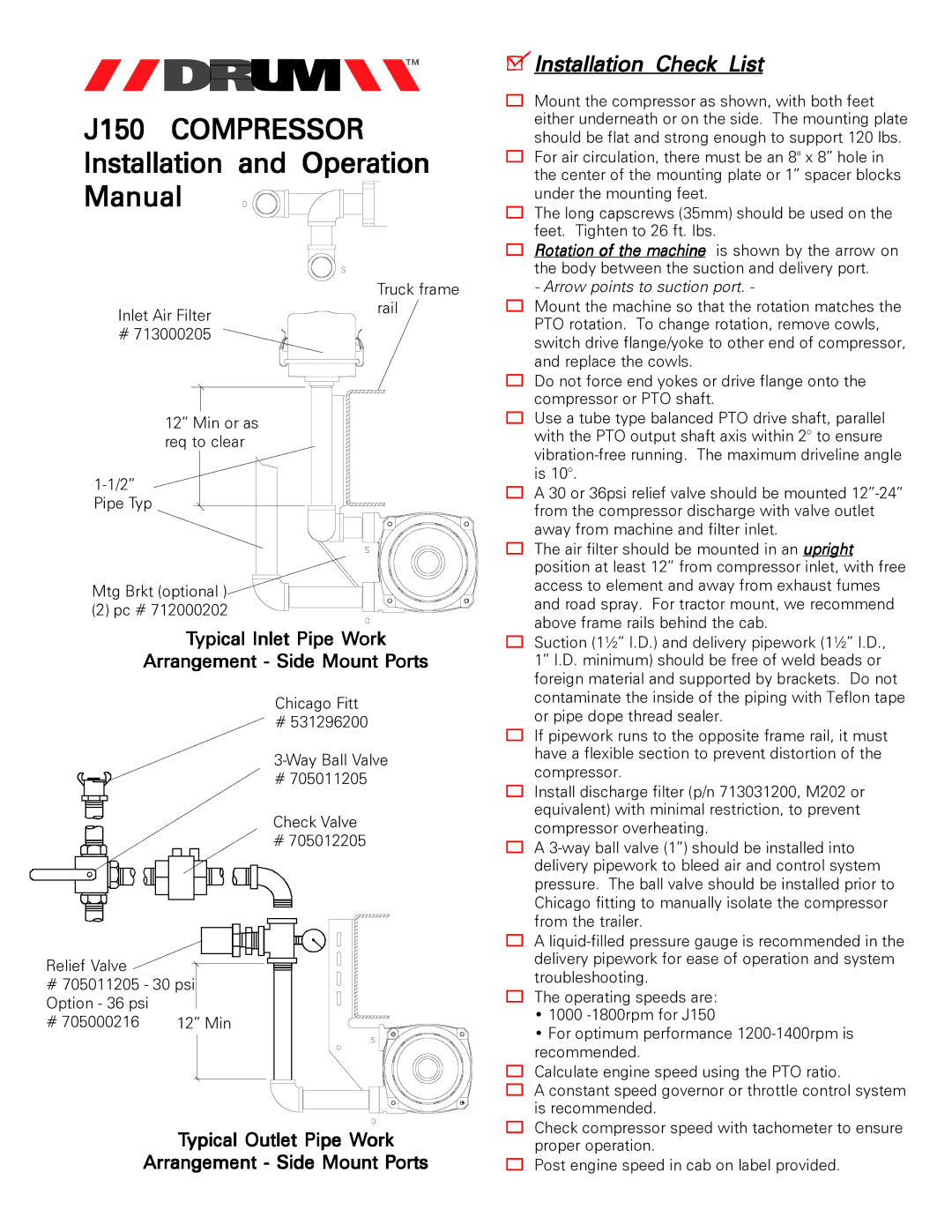

Truck frame

Inlet Air Filterrail

# 713000205

12” Min or as req to clear

Mtg Brkt (optional )![]()

(2) pc # 712000202

Typical Inlet Pipe Work

Arrangement - Side Mount Ports

Chicago Fitt

# 531296200

# 705011205

Check Valve

# 705012205

Relief Valve

#705011205 - 30 psi Option - 36 psi

# 705000216 | 12” Min |

Typical Outlet Pipe Work

Arrangement - Side Mount Ports

Installation Check List

Installation Check List

Mount the compressor as shown, with both feet either underneath or on the side. The mounting plate should be flat and strong enough to support 120 lbs.

For air circulation, there must be an 8" x 8” hole in the center of the mounting plate or 1” spacer blocks under the mounting feet.

The long capscrews (35mm) should be used on the feet. Tighten to 26 ft. lbs.

Rotation of the machine is shown by the arrow on the body between the suction and delivery port.

- Arrow points to suction port. -

Mount the machine so that the rotation matches the PTO rotation. To change rotation, remove cowls, switch drive flange/yoke to other end of compressor, and replace the cowls.

Do not force end yokes or drive flange onto the compressor or PTO shaft.

Use a tube type balanced PTO drive shaft, parallel with the PTO output shaft axis within 2° to ensure

A 30 or 36psi relief valve should be mounted

The air filter should be mounted in an upright position at least 12” from compressor inlet, with free access to element and away from exhaust fumes and road spray. For tractor mount, we recommend above frame rails behind the cab.

Suction (1½” I.D.) and delivery pipework (1½” I.D., 1” I.D. minimum) should be free of weld beads or foreign material and supported by brackets. Do not contaminate the inside of the piping with Teflon tape or pipe dope thread sealer.

If pipework runs to the opposite frame rail, it must have a flexible section to prevent distortion of the compressor.

Install discharge filter (p/n 713031200, M202 or equivalent) with minimal restriction, to prevent compressor overheating.

A

A

The operating speeds are:

•1000

•For optimum performance

Calculate engine speed using the PTO ratio.

A constant speed governor or throttle control system is recommended.

Check compressor speed with tachometer to ensure proper operation.

Post engine speed in cab on label provided.