GM 2000 EAC - EN

3. PREPARATION BEFORE STARTING WORK

Caution

The operating instructions and the safety regulations for the additional system components used must be read before

This spray gun must be used a part of an

The control units VM 200 EN, VM 2000 EN or EPP 200 EN and other various components are also needed (see

The spray gun and paint supply system must be flushed out with a suitable cleaning solvent before being used.

3.1Preparation of paint

The viscosity of the paints is of great importance. The best results are obtained with paints between 18 and 30 DIN sec. (measured in immersion flow cup DIN 4 mm). In most cases, the application of paints of up to

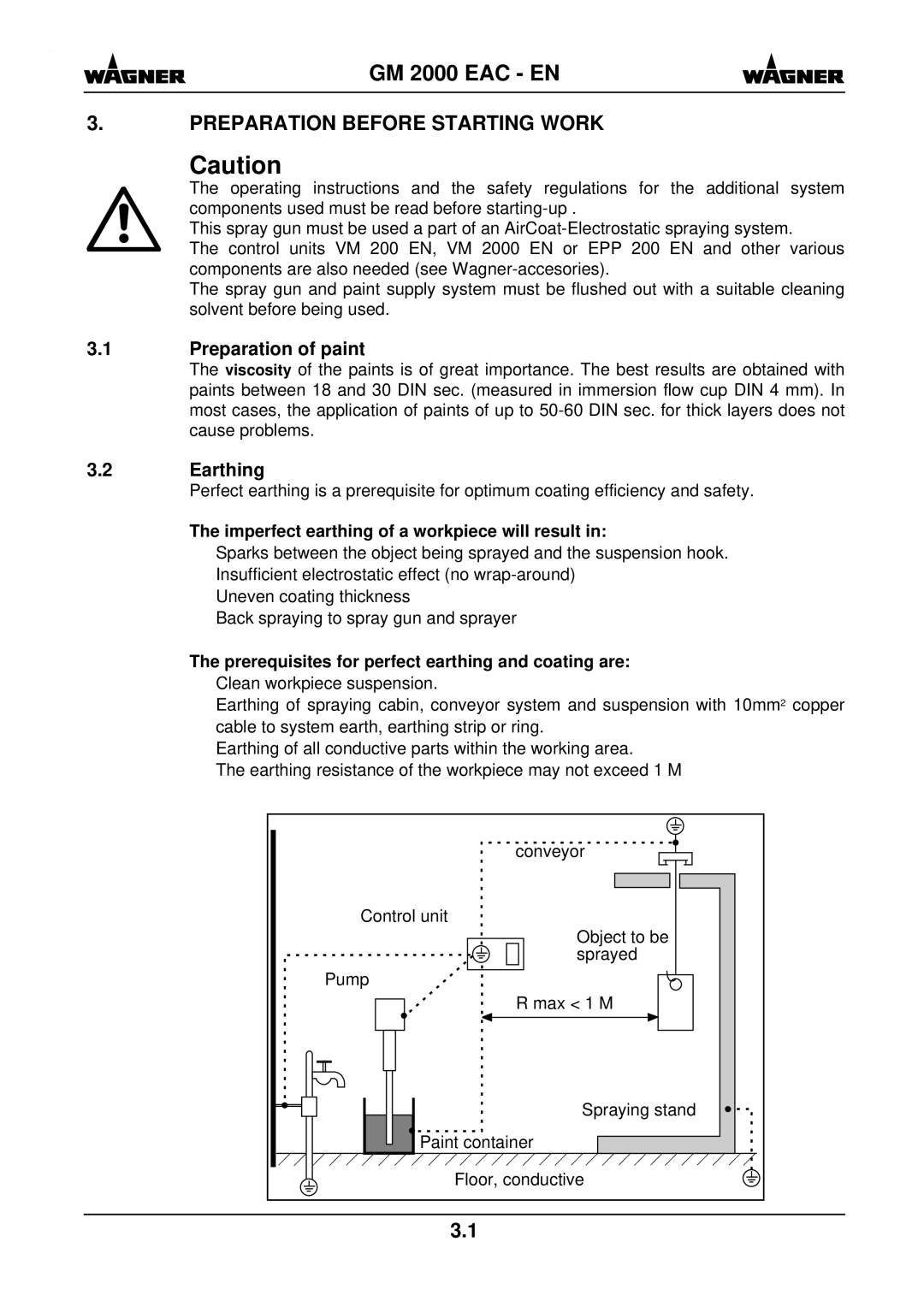

3.2Earthing

Perfect earthing is a prerequisite for optimum coating efficiency and safety.

The imperfect earthing of a workpiece will result in:

●Sparks between the object being sprayed and the suspension hook.

●Insufficient electrostatic effect (no

●Uneven coating thickness

●Back spraying to spray gun and sprayer

The prerequisites for perfect earthing and coating are:

●Clean workpiece suspension.

●Earthing of spraying cabin, conveyor system and suspension with 10mm2 copper cable to system earth, earthing strip or ring.

●Earthing of all conductive parts within the working area.

●The earthing resistance of the workpiece may not exceed 1 MΩ.

conveyor |

Control unit |

Object to be |

sprayed |

Pump |

R max < 1 M |

Spraying stand |

Paint container |

Floor, conductive |

3.1 |