GM 2000 EAC - EN

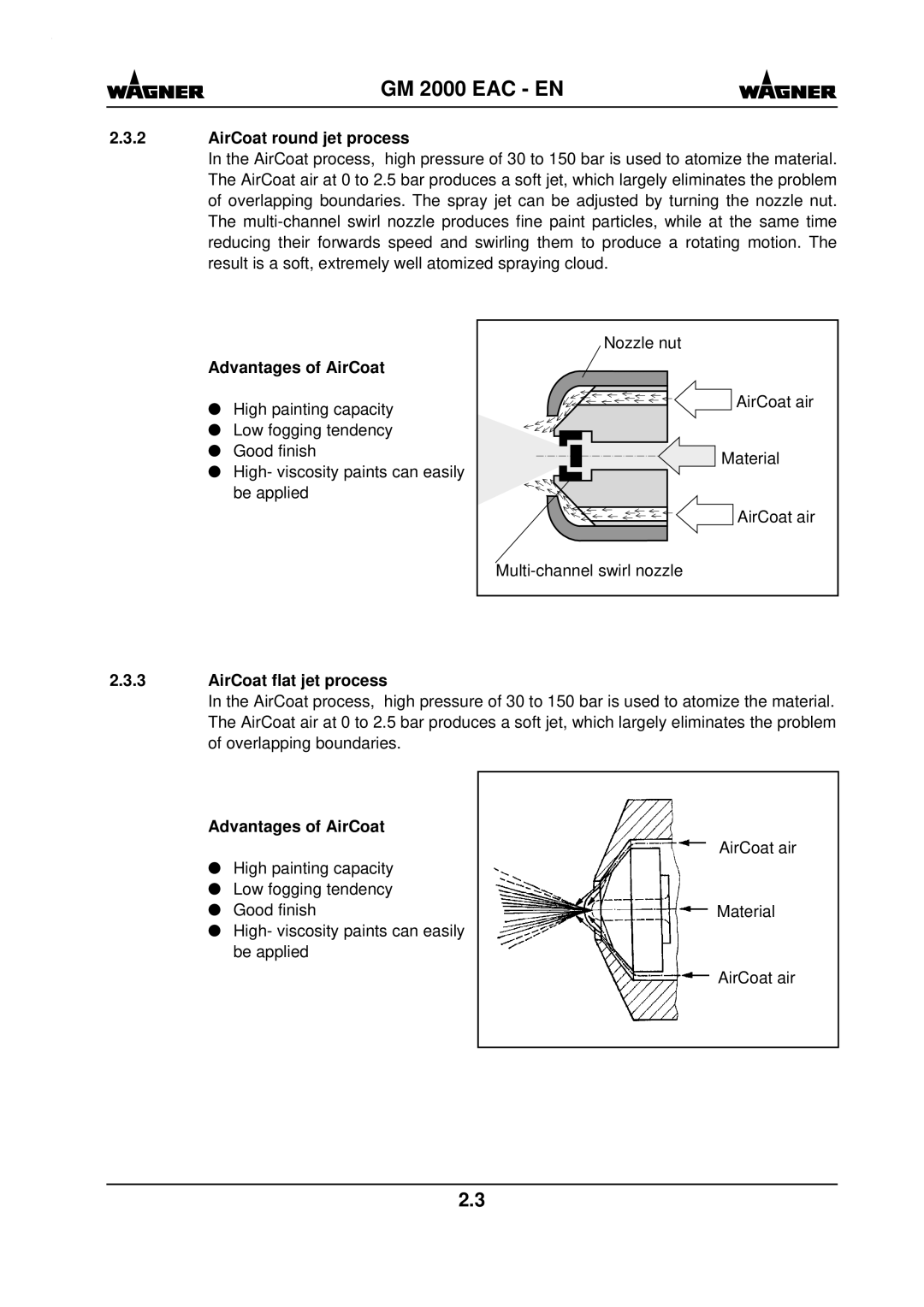

2.3.2AirCoat round jet process

In the AirCoat process, high pressure of 30 to 150 bar is used to atomize the material. The AirCoat air at 0 to 2.5 bar produces a soft jet, which largely eliminates the problem of overlapping boundaries. The spray jet can be adjusted by turning the nozzle nut. The

Advantages of AirCoat

●High painting capacity

●Low fogging tendency

●Good finish

●High- viscosity paints can easily be applied

Nozzle nut

AirCoat air

![]() Material

Material

AirCoat air

2.3.3AirCoat flat jet process

In the AirCoat process, high pressure of 30 to 150 bar is used to atomize the material. The AirCoat air at 0 to 2.5 bar produces a soft jet, which largely eliminates the problem of overlapping boundaries.

Advantages of AirCoat

●High painting capacity

●Low fogging tendency

●Good finish

●High- viscosity paints can easily be applied

AirCoat air

Material

AirCoat air

2.3