CLEANUP (CONTINUED)

INLET/OUTLET VALVES

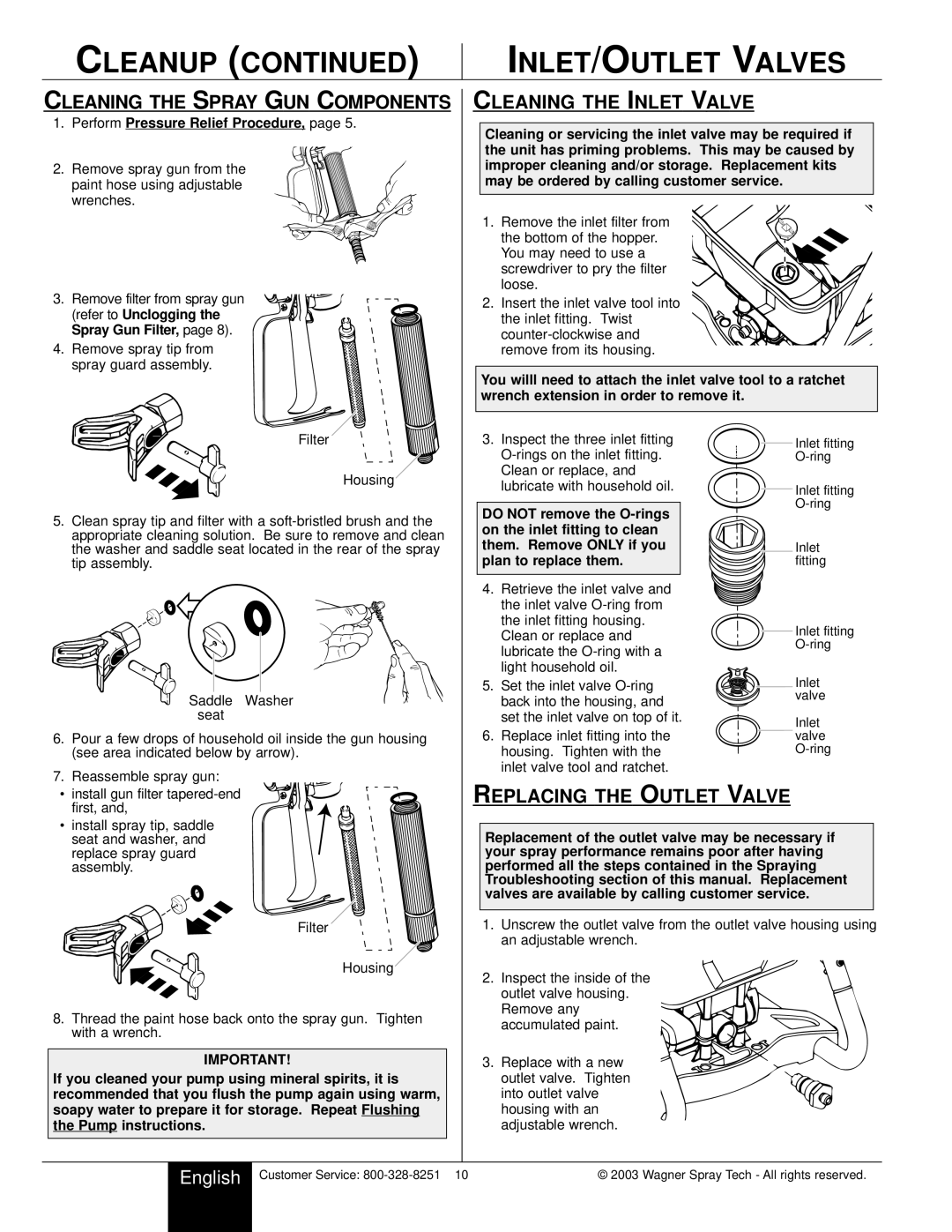

CLEANING THE SPRAY GUN COMPONENTS

1.Perform Pressure Relief Procedure, page 5.

2. Remove spray gun from the paint hose using adjustable wrenches.

3. Remove filter from spray gun (refer to Unclogging the Spray Gun Filter, page 8).

4. Remove spray tip from spray guard assembly.

CLEANING THE INLET VALVE

Cleaning or servicing the inlet valve may be required if the unit has priming problems. This may be caused by improper cleaning and/or storage. Replacement kits may be ordered by calling customer service.

1. Remove the inlet filter from the bottom of the hopper. You may need to use a screwdriver to pry the filter loose.

2. Insert the inlet valve tool into the inlet fitting. Twist

You willl need to attach the inlet valve tool to a ratchet wrench extension in order to remove it.

Filter

Housing

5.Clean spray tip and filter with a

Saddle Washer seat

6.Pour a few drops of household oil inside the gun housing (see area indicated below by arrow).

7.Reassemble spray gun:

3.Inspect the three inlet fitting

DO NOT remove the

4.Retrieve the inlet valve and the inlet valve

5.Set the inlet valve

6.Replace inlet fitting into the housing. Tighten with the inlet valve tool and ratchet.

![]() Inlet fitting

Inlet fitting

![]() Inlet fitting

Inlet fitting

![]() Inlet fitting

Inlet fitting

![]() Inlet fitting

Inlet fitting

![]() Inlet valve

Inlet valve

Inlet valve

• install gun filter

• install spray tip, saddle seat and washer, and replace spray guard assembly.

Filter

Housing

8.Thread the paint hose back onto the spray gun. Tighten with a wrench.

IMPORTANT!

If you cleaned your pump using mineral spirits, it is recommended that you flush the pump again using warm, soapy water to prepare it for storage. Repeat Flushing the Pump instructions.

REPLACING THE OUTLET VALVE

Replacement of the outlet valve may be necessary if your spray performance remains poor after having performed all the steps contained in the Spraying Troubleshooting section of this manual. Replacement valves are available by calling customer service.

1.Unscrew the outlet valve from the outlet valve housing using an adjustable wrench.

2. Inspect the inside of the outlet valve housing. Remove any accumulated paint.

3. Replace with a new outlet valve. Tighten into outlet valve housing with an adjustable wrench.

English | Customer Service: | © 2003 Wagner Spray Tech - All rights reserved. |

|

|

|