5255, 5150, 5200, 5155 specifications

Wayne-Dalton is recognized for its high-quality garage doors, and its models 5155, 5255, 5150, and 5200 stand out for their durability, aesthetics, and advanced technology. These models are designed to cater to a variety of residential needs while ensuring reliability and performance.The Wayne-Dalton 5155 and 5255 models are part of the brand’s premium line of insulated garage doors. The 5155 features a polystyrene core that provides excellent insulation, while the 5255 enhances energy efficiency with a polyurethane core, offering higher R-values for superior thermal performance. This makes them especially suitable for homeowners in climates with extreme temperatures, as they help maintain consistent indoor conditions.

Both models boast a beautiful design that complements any home style. The doors come in various panel designs and colors, allowing homeowners to customize their garage doors to fit their personal aesthetic. The 5155 and 5255 also feature a durable, low-maintenance exterior, crafted from high-quality materials that resist rust and corrosion, ensuring long-lasting performance.

Moving on to the Wayne-Dalton 5150 and 5200 models, these doors focus more on traditional designs while still offering modern functionality. The 5150 model features a classic raised panel design, perfect for those seeking a timeless look. On the other hand, the 5200 is known for its versatility and range of design options, allowing for greater customization.

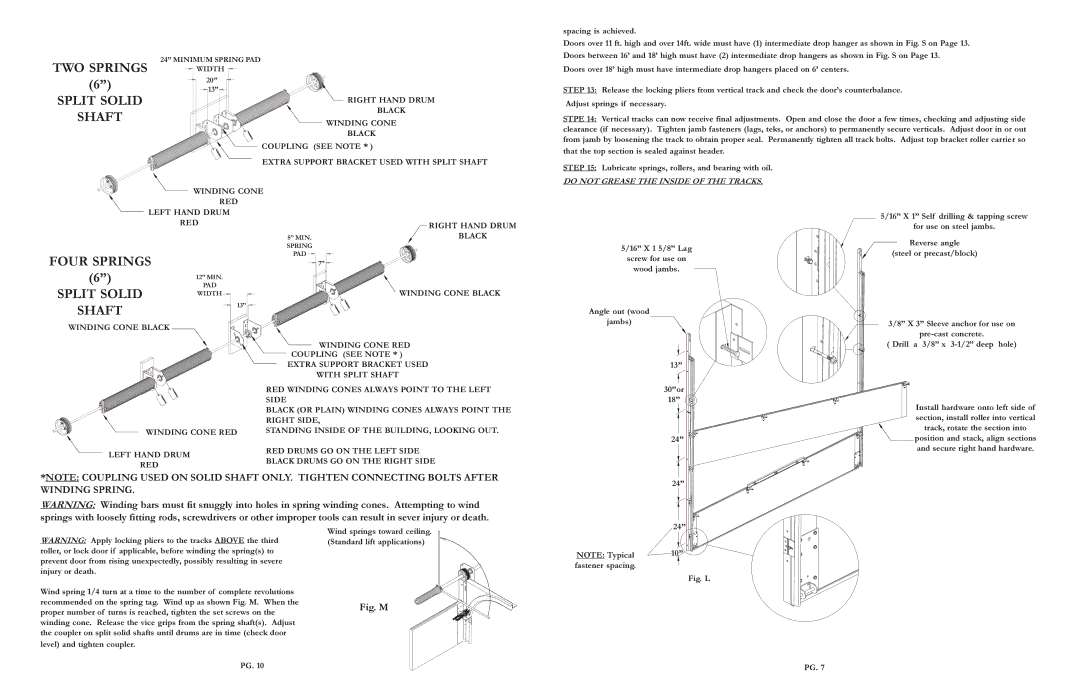

Both models integrate advanced safety features such as pinch-resistant design, ensuring the safety of family members and pets. They are equipped with a reliable torsion spring system that offers smooth and quiet operation, making them ideal for homes where noise reduction is a priority.

Furthermore, the innovative technology employed in these Wayne-Dalton models enhances their operability and security. The doors are compatible with automatic door openers, and some models can integrate smart technology, allowing for remote access and monitoring through smartphones.

In summary, Wayne-Dalton’s 5155, 5255, 5150, and 5200 models exemplify the brand’s commitment to quality, aesthetics, and technology. Each model caters to different homeowner needs, whether it's insulation, design, or advanced features, ensuring there is a perfect garage door for every residential application.