Operating Instructions and Parts Manual | | | Model ISP40 | Operating Instructions And Parts Manual | | | | | | Model ISP40 |

For Replacement Parts, call 1-800-237-0987 | | Battery Information | | CHART 2 - PS/BC STATUS LIGHTS | | |

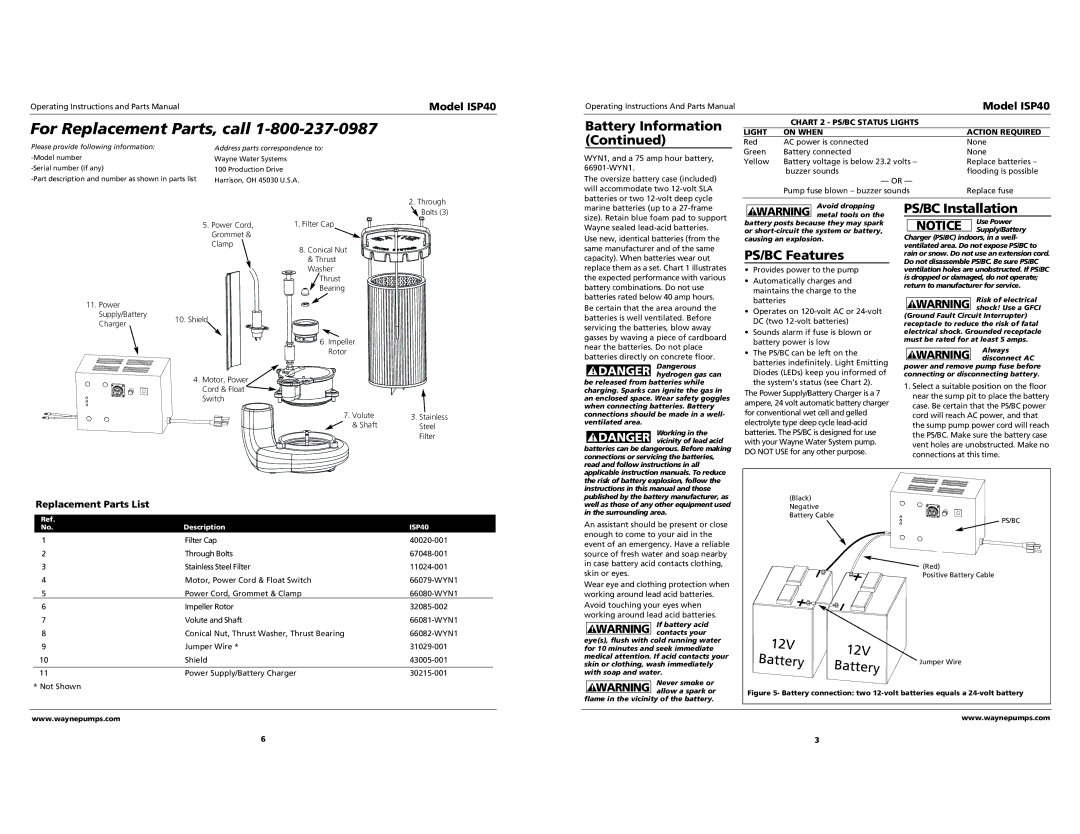

| LIGHT | ON WHEN | | ACTION REQUIRED |

Please provide following information: | | Address parts correspondence to: | | (Continued) | Red | AC power is connected | | None |

| | | Green | Battery connected | | None |

-Model number | | Wayne Water Systems | | | WYN1, and a 75 amp hour battery, | |

| | | Yellow | Battery voltage is below 23.2 volts – | Replace batteries – |

-Serial number (if any) | | 100 Production Drive | | | 66901-WYN1. |

| | | | buzzer sounds | | flooding is possible |

-Part description and number as shown in parts list | Harrison, OH 45030 U.S.A. | | The oversize battery case (included) | | | — OR — | | |

| | | | | will accommodate two 12-volt SLA | | Pump fuse blown – buzzer sounds | Replace fuse |

| | | | 2. Through | batteries or two 12-volt deep cycle | | | Avoid dropping | PS/BC Installation |

| | | | marine batteries (up to a 27-frame | ! WARNING |

| | | | Bolts (3) |

| | | | size). Retain blue foam pad to support | metal tools on the |

| | 5. Power Cord, | 1. Filter Cap | | battery posts because they may spark | NOTICE | | Use Power |

| | | Wayne sealed lead-acid batteries. | |

| | Grommet & | | | or short-circuit the system or battery, | | Supply/Battery |

| | | | Use new, identical batteries (from the | causing an explosion. | Charger (PS/BC) indoors, in a well- |

| | Clamp | | |

| | 8. Conical Nut | | same manufacturer and of the same | PS/BC Features | ventilated area. Do not expose PS/BC to |

| | | | rain or snow. Do not use an extension cord. |

| | | & Thrust | | capacity). When batteries wear out |

| | | | Do not disassemble PS/BC. Be sure PS/BC |

| | | Washer | | replace them as a set. Chart 1 illustrates | • Provides power to the pump | ventilation holes are unobstructed. If PS/BC |

| | | Thrust | | the expected performance with various | • Automatically charges and | is dropped or damaged, do not operate; |

| | | Bearing | | battery combinations. Do not use | maintains the charge to the | return to manufacturer for service. |

| | | | | batteries rated below 40 amp hours. | | | |

11. Power | | | | | batteries | | ! WARNING | Risk of electrical |

| | | | | |

| | | | Be certain that the area around the | • Operates on 120-volt AC or 24-volt | shock! Use a GFCI |

Supply/Battery | 10. Shield | | | batteries is well ventilated. Before | (Ground Fault Circuit Interrupter) |

| | DC (two 12-volt batteries) |

Charger | | | receptacle to reduce the risk of fatal |

| | | | servicing the batteries, blow away | | | |

| | | | | • Sounds alarm if fuse is blown or | electrical shock. Grounded receptacle |

| | | | | gasses by waving a piece of cardboard |

| | | 6. Impeller | | battery power is low | must be rated for at least 5 amps. |

| | | | near the batteries. Do not place |

| | | Rotor | | • The PS/BC can be left on the | ! WARNING | Always |

| | | | batteries directly on concrete floor. |

| | | | | batteries indefinitely. Light Emitting | disconnect AC |

| | | | | Dangerous | power and remove pump fuse before |

| | | | | | | |

| 4. Motor, Power | | | ! DANGER hydrogen gas can | Diodes (LEDs) keep you informed of | connecting or disconnecting battery. |

| | | be released from batteries while | the system’s status (see Chart 2). | 1. Select a suitable position on the floor |

| | Cord & Float | | |

| | | | charging. Sparks can ignite the gas in | The Power Supply/Battery Charger is a 7 |

| | | | near the sump pit to place the battery |

| | Switch | | | an enclosed space. Wear safety goggles |

| | | | ampere, 24 volt automatic battery charger |

| | | | | when connecting batteries. Battery | case. Be certain that the PS/BC power |

| | | | | for conventional wet cell and gelled |

| | | 7. Volute | 3. Stainless | connections should be made in a well- | cord will reach AC power, and that |

| | | ventilated area. | electrolyte type deep cycle lead-acid |

| | | & Shaft | Steel | the sump pump power cord will reach |

| | | Working in the | batteries. The PS/BC is designed for use |

| | | | Filter | the PS/BC. Make sure the battery case |

| | | | ! DANGER vicinity of lead acid | with your Wayne Water System pump. |

| | | | | vent holes are unobstructed. Make no |

| | | | | batteries can be dangerous. Before making | DO NOT USE for any other purpose. |

| | | | | connections at this time. |

| | | | | connections or servicing the batteries, |

| | | | | | | |

| | | | | read and follow instructions in all | | | | | | |

| | | | | applicable instruction manuals. To reduce | | | | | | |

| | | | | the risk of battery explosion, follow the | | | | | | |

| | | | | instructions in this manual and those | | | | | | |

Replacement Parts List | | | | | published by the battery manufacturer, as | | (Black) | | | | |

| | | | well as those of any other equipment used | | Negative | | | |

Ref. | | | | | in the surrounding area. | | Battery Cable | | | PS/BC |

| | | | | | | |

Description | | ISP40 | An assistant should be present or close | | | | | |

No. | | | | | | | |

1 | Filter Cap | | 40020-001 | enough to come to your aid in the | | | | | | |

| event of an emergency. Have a reliable | | | | | | |

| | | | | | | | | | |

2 | Through Bolts | | 67048-001 | source of fresh water and soap nearby | | | | | | |

3 | Stainless Steel Filter | | 11024-001 | in case battery acid contacts clothing, | | | | (Red) | | |

| skin or eyes. | | | | | |

4 | Motor, Power Cord & Float Switch | 66079-WYN1 | | | | Positive Battery Cable |

Wear eye and clothing protection when | | | | | | |

5 | Power Cord, Grommet & Clamp | 66080-WYN1 | | | | | | |

working around lead acid batteries. | | | | | | |

6 | Impeller Rotor | | 32085-002 | Avoid touching your eyes when | | | | | | |

7 | Volute and Shaft | | 66081-WYN1 | working around lead acid batteries. | | | | | | |

| If battery acid | | | | | | |

| | | | | | | | | | |

8 | Conical Nut, Thrust Washer, Thrust Bearing | 66082-WYN1 | ! WARNING contacts your | | 12V | | | | |

9 | Jumper Wire * | | 31029-001 | eye(s), flush with cold running water | | 12V | | | |

| for 10 minutes and seek immediate | | | | |

10 | Shield | | 43005-001 | medical attention. If acid contacts your | Battery | | | |

| Battery | Jumper Wire | | |

| skin or clothing, wash immediately | | |

11 | Power Supply/Battery Charger | 30215-001 | with soap and water. | | | | | |

| | | | | |

* Not Shown | | | | | Never smoke or | | | | | | |

| | | | ! WARNING allow a spark or | Figure 5- Battery connection: two 12-volt batteries equals a 24-volt battery |

| | | | |

| | | | | flame in the vicinity of the battery. | | | | | | |

www.waynepumps.com | | | | | | | | | www.waynepumps.com |

| | 6 | | | | | | 3 | | | |