Submersible Series, 350705-001 specifications

The Wayne Submersible Series 350705-001 is a highly regarded solution in the realm of sewage and wastewater management. This powerful submersible pump is engineered to deliver high performance and reliability, making it an essential tool for residential and commercial applications alike.One of the standout features of the Wayne Submersible 350705-001 is its robust construction. The durable cast iron housing is designed to withstand the harsh conditions typically found in sewage applications, ensuring longevity and resilience. With a power rating of 1/2 horsepower, this pump is capable of handling high volumes of wastewater, while its efficient motor operates quietly, reducing noise pollution in the environment.

The pump boasts a maximum flow rate of approximately 60 gallons per minute, making it suitable for a variety of settings, including basements, drainage pits, and effluent waste management systems. It features a reliable vortex impeller, which efficiently handles solids up to 2 inches in diameter, preventing clogging and ensuring uninterrupted operation. The unique design of the impeller also allows for better flow rates and higher efficiency, ultimately leading to reduced energy consumption.

Another significant aspect of the Wayne Submersible 350705-001 is its innovative float switch technology. Designed for automatic operation, this float switch can detect water levels and activate the pump as needed, providing hassle-free operation and peace of mind for users. This feature not only aids in maintaining desired water levels but also significantly reduces the risk of flooding in critical areas.

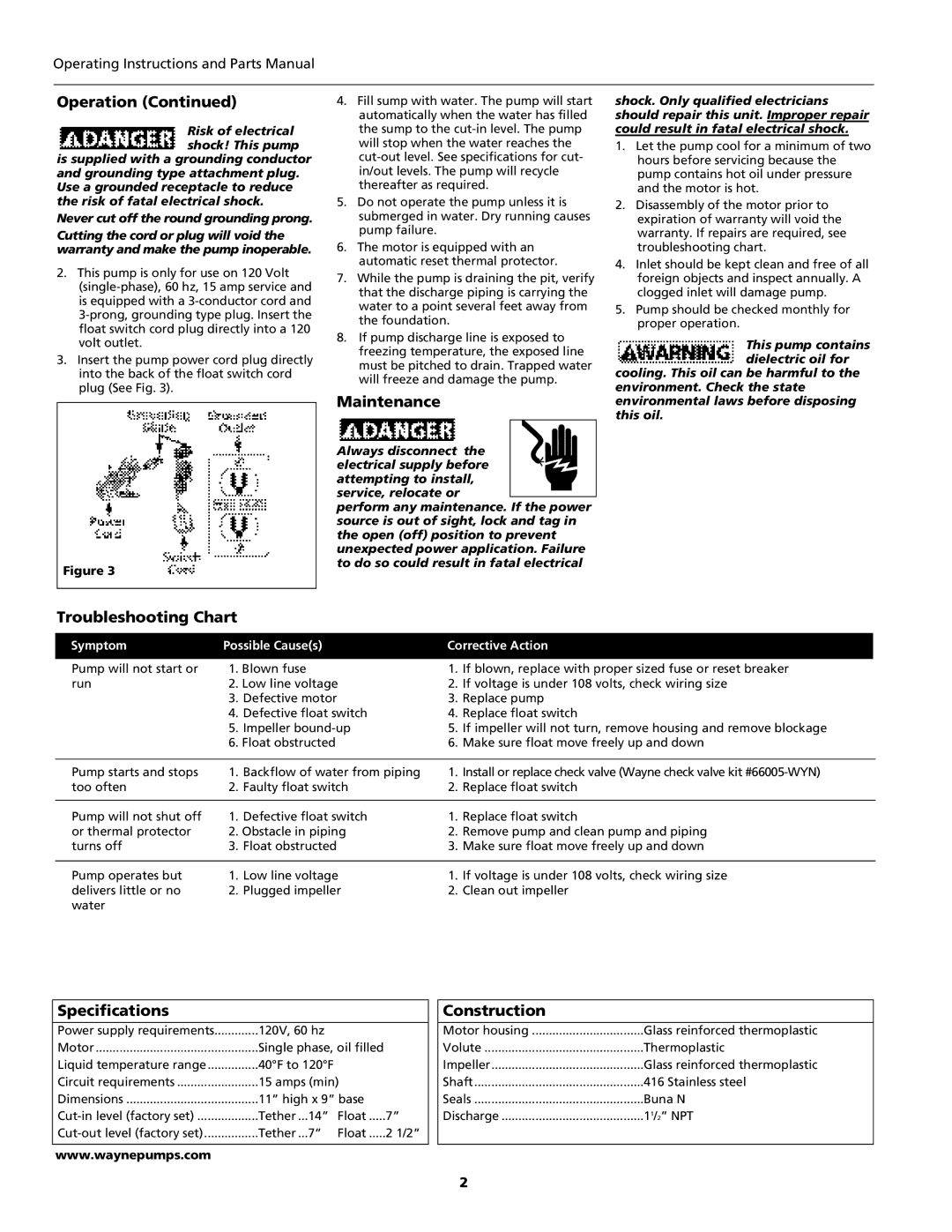

Easy installation is a hallmark of the Wayne Submersible pump series. The 350705-001 comes with a standard 1-1/2 inch discharge, compatible with most existing plumbing systems. Its compact design also allows it to fit in tight spaces, making it versatile for various setups.

With a commitment to quality and performance, Wayne stands behind its products with a warranty, offering customers further assurance of their investment. The combination of strength, efficiency, and user-friendly design makes the Wayne Submersible Series 350705-001 an excellent choice for anyone in need of effective wastewater management solutions. Whether for residential use in a basement or for more extensive commercial systems, this pump stands out as a reliable ally in tackling challenging water removal tasks.