Operating Instructions and Parts Manual | Deep Well Submersible Pump |

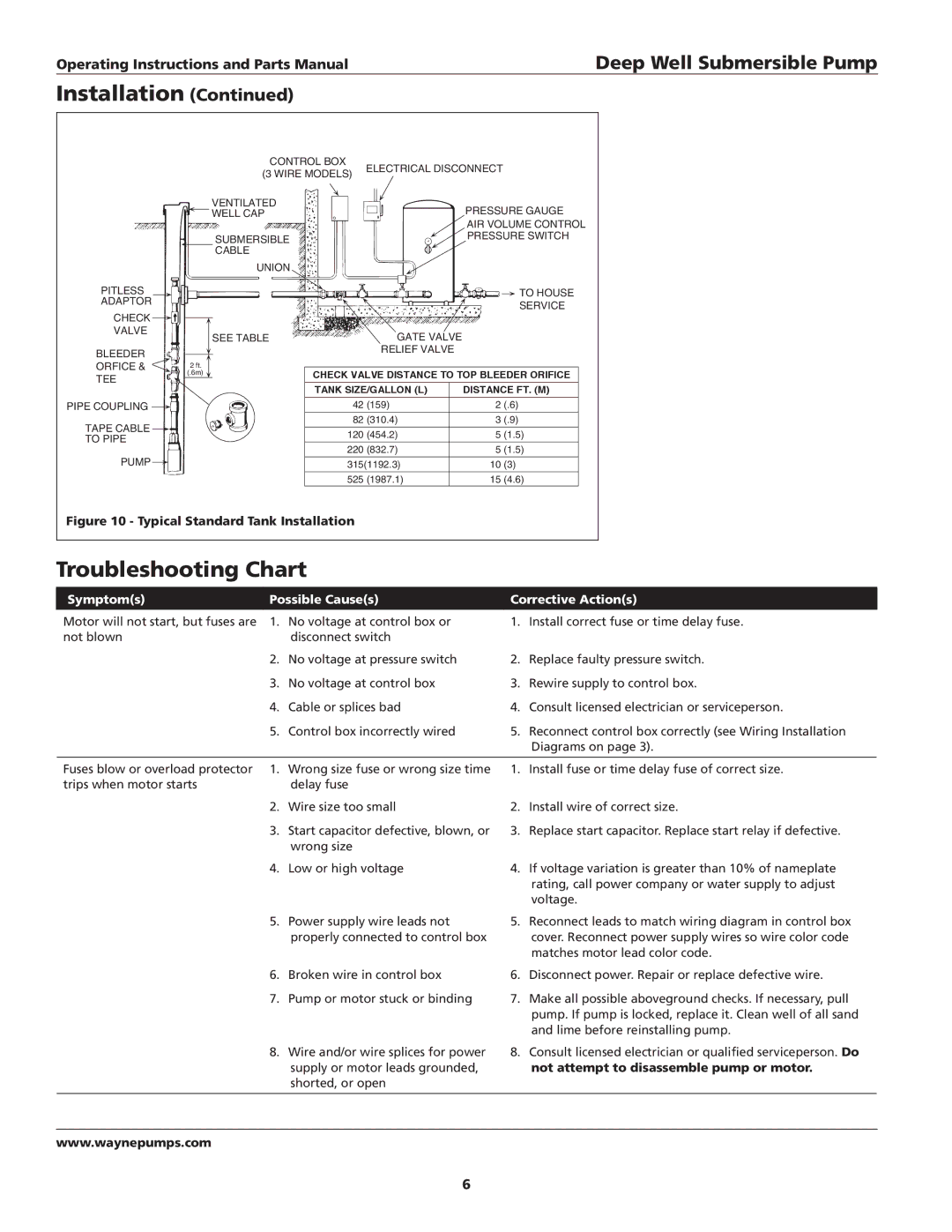

Installation (Continued) |

|

|

|

| |

| CONTROL BOX |

| ELECTRICAL DISCONNECT | ||

| (3 WIRE MODELS) | ||||

|

|

| |||

| VENTILATED |

|

|

| PRESSURE GAUGE |

| WELL CAP |

|

|

| |

|

|

|

|

| AIR VOLUME CONTROL |

| SUBMERSIBLE |

|

|

| PRESSURE SWITCH |

|

|

|

|

| |

| CABLE |

|

|

|

|

| UNION |

|

|

|

|

PITLESS |

|

|

|

| TO HOUSE |

ADAPTOR |

|

|

|

| SERVICE |

|

|

|

|

| |

CHECK |

|

|

|

|

|

VALVE | SEE TABLE |

|

| GATE VALVE |

|

|

|

|

| ||

BLEEDER |

|

|

| RELIEF VALVE |

|

|

|

|

|

| |

ORFICE & | 2 ft. | CHECK VALVE DISTANCE TO TOP BLEEDER ORIFICE | |||

TEE | (.6m) | ||||

| |||||

|

| TANK SIZE/GALLON (L) | DISTANCE FT. (M) | ||

PIPE COUPLING |

|

|

| 42 (159) | 2 (.6) |

TAPE CABLE |

|

|

| 82 (310.4) | 3 (.9) |

|

| 120 (454.2) | 5 (1.5) | ||

TO PIPE |

|

| |||

|

| 220 (832.7) | 5 (1.5) | ||

|

|

| |||

PUMP |

|

| 315(1192.3) | 10 (3) | |

|

|

| 525 (1987.1) | 15 (4.6) | |

Figure 10 - Typical Standard Tank Installation |

| ||||

Troubleshooting Chart

Symptom(s)

Motor will not start, but fuses are not blown

Possible Cause(s)

1.No voltage at control box or disconnect switch

2.No voltage at pressure switch

3.No voltage at control box

4.Cable or splices bad

5.Control box incorrectly wired

Corrective Action(s)

1.Install correct fuse or time delay fuse.

2.Replace faulty pressure switch.

3.Rewire supply to control box.

4.Consult licensed electrician or serviceperson.

5.Reconnect control box correctly (see Wiring Installation Diagrams on page 3).

Fuses blow or overload protector trips when motor starts

1.Wrong size fuse or wrong size time delay fuse

2.Wire size too small

3.Start capacitor defective, blown, or wrong size

1.Install fuse or time delay fuse of correct size.

2.Install wire of correct size.

3.Replace start capacitor. Replace start relay if defective.

4. Low or high voltage | 4. If voltage variation is greater than 10% of nameplate |

| rating, call power company or water supply to adjust |

| voltage. |

5.Power supply wire leads not properly connected to control box

5.Reconnect leads to match wiring diagram in control box cover. Reconnect power supply wires so wire color code matches motor lead color code.

6.Broken wire in control box

7.Pump or motor stuck or binding

8.Wire and/or wire splices for power supply or motor leads grounded, shorted, or open

6.Disconnect power. Repair or replace defective wire.

7.Make all possible aboveground checks. If necessary, pull pump. If pump is locked, replace it. Clean well of all sand and lime before reinstalling pump.

8.Consult licensed electrician or qualified serviceperson. Do not attempt to disassemble pump or motor.

www.waynepumps.com

6