WSS10, WSS20, WSS30

Maintenance - Back-up Pump (continued)

3.For batteries with top caps that can be removed, the electrolyte level should be checked and filled to manufacturer’s specifications. The charge for each cell should be checked with a hydrometer. A specific gravity of 1.265 indicates the battery is at full charge. If the specific gravity of any of the cells varies more than .050, the battery should be replaced.

NOTE: An inexpensive hydrometer can be purchased at an automotive parts dealer.

4.Inspect the terminals and clamps for corrosion and tightness. Clean and tighten as required.

5.Unplug the main pump and fill sump with water until back up pump turns on. Repeat process two times to be sure pump is operating normally.

6.If pump operates normally, plug charger into wall outlet, turn on main pump. If pump fails to operate normally, see Troubleshooting guide and correct problem. Repeat step 5.

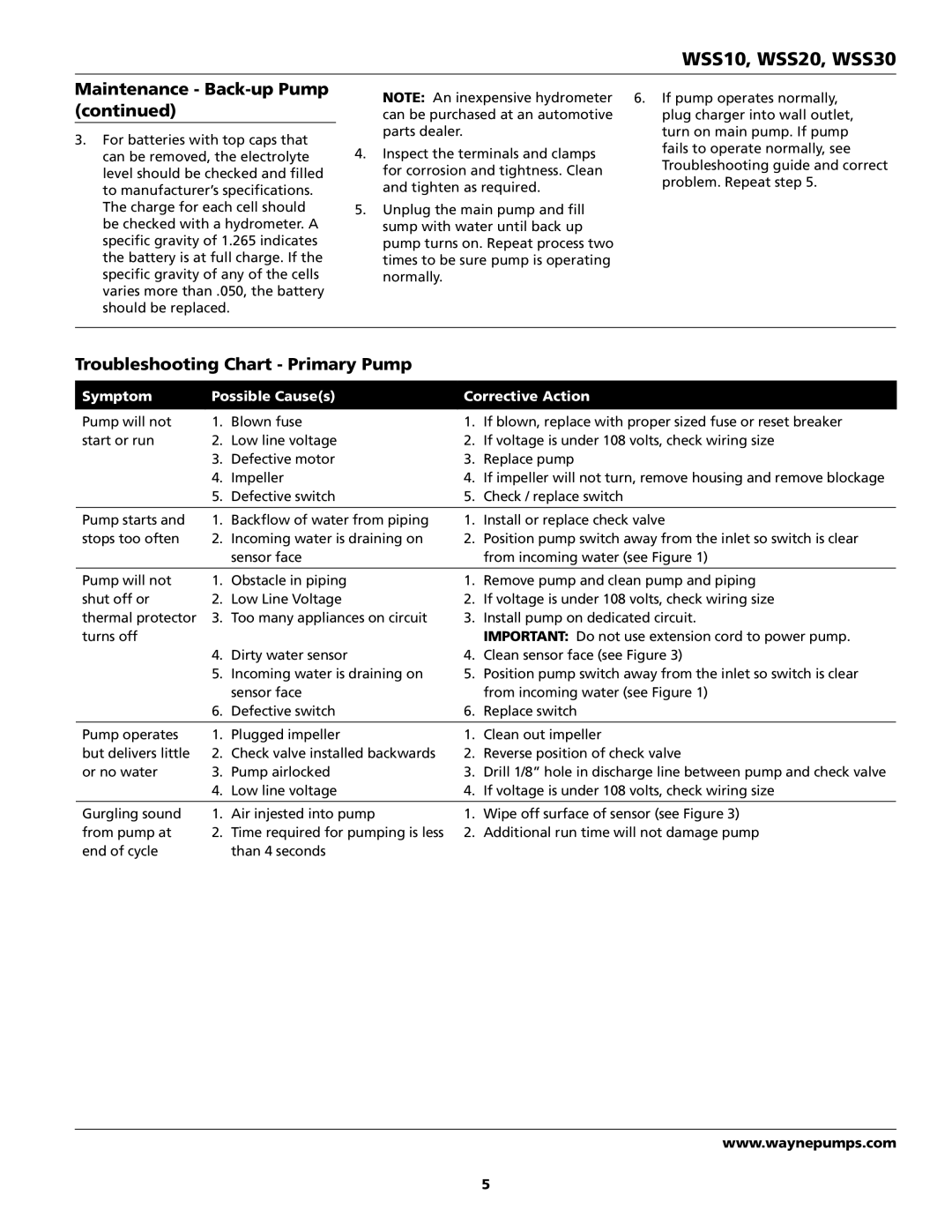

Troubleshooting Chart - Primary Pump

Symptom

Possible Cause(s)

Corrective Action

Pump will not | 1. | Blown fuse | 1. | If blown, replace with proper sized fuse or reset breaker |

start or run | 2. | Low line voltage | 2. | If voltage is under 108 volts, check wiring size |

| 3. | Defective motor | 3. | Replace pump |

| 4. | Impeller | 4. | If impeller will not turn, remove housing and remove blockage |

| 5. | Defective switch | 5. | Check / replace switch |

|

|

|

|

|

Pump starts and | 1. | Backflow of water from piping | 1. | Install or replace check valve |

stops too often | 2. | Incoming water is draining on | 2. | Position pump switch away from the inlet so switch is clear |

|

| sensor face |

| from incoming water (see Figure 1) |

|

|

|

| |

Pump will not | 1. Obstacle in piping | 1. | Remove pump and clean pump and piping | |

shut off or | 2. | Low Line Voltage | 2. | If voltage is under 108 volts, check wiring size |

thermal protector | 3. | Too many appliances on circuit | 3. | Install pump on dedicated circuit. |

turns off |

|

|

| IMPORTANT: Do not use extension cord to power pump. |

| 4. | Dirty water sensor | 4. | Clean sensor face (see Figure 3) |

| 5. | Incoming water is draining on | 5. | Position pump switch away from the inlet so switch is clear |

|

| sensor face |

| from incoming water (see Figure 1) |

| 6. | Defective switch | 6. | Replace switch |

|

|

|

|

|

Pump operates | 1. | Plugged impeller | 1. | Clean out impeller |

but delivers little | 2. | Check valve installed backwards | 2. | Reverse position of check valve |

or no water | 3. | Pump airlocked | 3. | Drill 1/8” hole in discharge line between pump and check valve |

| 4. | Low line voltage | 4. | If voltage is under 108 volts, check wiring size |

|

|

|

|

|

Gurgling sound | 1. | Air injested into pump | 1. | Wipe off surface of sensor (see Figure 3) |

from pump at | 2. | Time required for pumping is less | 2. | Additional run time will not damage pump |

end of cycle |

| than 4 seconds |

|

|

www.waynepumps.com

5