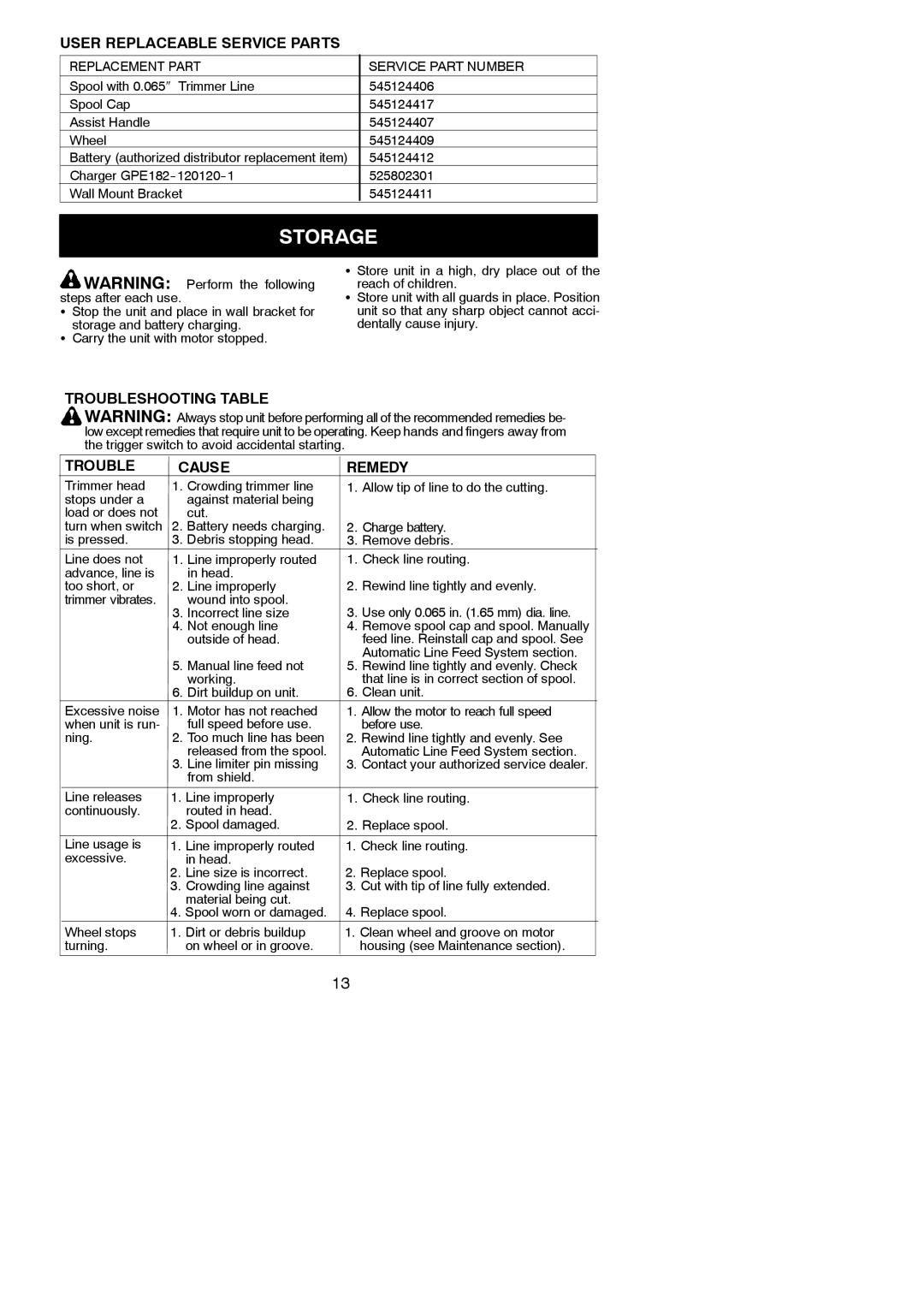

USER REPLACEABLE SERVICE PARTS

REPLACEMENT PART | SERVICE PART NUMBER |

Spool with 0.065″ Trimmer Line | 545124406 |

Spool Cap | 545124417 |

Assist Handle | 545124407 |

Wheel | 545124409 |

Battery (authorized distributor replacement item) | 545124412 |

Charger | 525802301 |

Wall Mount Bracket | 545124411 |

STORAGE

![]() WARNING: Perform the following steps after each use.

WARNING: Perform the following steps after each use.

SStop the unit and place in wall bracket for storage and battery charging.

SCarry the unit with motor stopped.

S Store unit in a high, dry place out of the reach of children.

SStore unit with all guards in place. Position unit so that any sharp object cannot acci- dentally cause injury.

TROUBLESHOOTING TABLE

WARNING: Always stop unit before performing all of the recommended remedies be- low except remedies that require unit to be operating. Keep hands and fingers away from the trigger switch to avoid accidental starting.

TROUBLE | CAUSE | REMEDY |

Trimmer head | 1. | Crowding trimmer line |

stops under a |

| against material being |

load or does not |

| cut. |

turn when switch | 2. | Battery needs charging. |

is pressed. | 3. | Debris stopping head. |

Line does not | 1. | Line improperly routed |

advance, line is |

| in head. |

too short, or | 2. | Line improperly |

trimmer vibrates. |

| wound into spool. |

| 3. | Incorrect line size |

| 4. | Not enough line |

|

| outside of head. |

| 5. | Manual line feed not |

|

| working. |

| 6. | Dirt buildup on unit. |

Excessive noise | 1. | Motor has not reached |

when unit is run- |

| full speed before use. |

ning. | 2. | Too much line has been |

|

| released from the spool. |

| 3. | Line limiter pin missing |

|

| from shield. |

1.Allow tip of line to do the cutting.

2.Charge battery.

3.Remove debris.

1.Check line routing.

2.Rewind line tightly and evenly.

3.Use only 0.065 in. (1.65 mm) dia. line.

4.Remove spool cap and spool. Manually feed line. Reinstall cap and spool. See Automatic Line Feed System section.

5.Rewind line tightly and evenly. Check that line is in correct section of spool.

6.Clean unit.

1.Allow the motor to reach full speed before use.

2.Rewind line tightly and evenly. See Automatic Line Feed System section.

3.Contact your authorized service dealer.

| Line releases | 1. Line improperly | 1. Check line routing. | ||

| continuously. |

| routed in head. |

|

|

|

| 2. | Spool damaged. | 2. Replace spool. | |

|

|

|

|

|

|

| Line usage is | 1. | Line improperly routed | 1. | Check line routing. |

| excessive. |

| in head. |

|

|

|

| 2. | Line size is incorrect. | 2. | Replace spool. |

|

| 3. | Crowding line against | 3. | Cut with tip of line fully extended. |

|

|

| material being cut. | 4. | Replace spool. |

|

| 4. | Spool worn or damaged. | ||

| Wheel stops | 1. | Dirt or debris buildup | 1. Clean wheel and groove on motor | |

| turning. |

| on wheel or in groove. |

| housing (see Maintenance section). |

13