FX25, XT250 specifications

The Weed Eater XT250 and FX25 are two powerful options in the realm of outdoor power equipment, designed specifically for homeowners seeking efficient and reliable solutions for their lawn care needs. These trimmers stand out due to their thoughtful engineering and user-friendly features, making yard maintenance a breeze.Starting with the Weed Eater XT250, one of its main features is the lightweight design, which allows for easy maneuverability. Weighing in at just under 10 pounds, it’s designed to reduce user fatigue, enabling longer periods of use without discomfort. This trimmer is equipped with a robust 25cc Gas-Powered Engine, offering ample power to tackle a range of grass and weed types. The XT250 also incorporates an automatic line feed system that ensures continuous cutting, reducing downtime for line replacement.

Additionally, the XT250’s adjustable cutting width allows users to adapt the trimmer to different tasks, whether it’s edging along sidewalks or clearing thick brush. The curved shaft design enhances control and precision while trimming in tight spaces, making it perfect for intricate yard work.

Shifting to the FX25 model, it boasts an impressive combination of performance and technology. Similar to the XT250, the FX25 features a 25cc engine but incorporates advanced vibration-dampening technology to minimize user fatigue during extended use. This model is ideal for users who require a dependable trimmer for both residential lawn care and light commercial use.

The FX25 also includes a dual-line bump feed head, which allows users to easily advance cutting line with just a tap on the ground, increasing efficiency and convenience. Its ergonomic handle design enhances comfort and grip, providing a secure hold while tackling tough jobs. Furthermore, the FX25's easy-start mechanism reduces the pull effort needed to start the engine, streamlining the user experience.

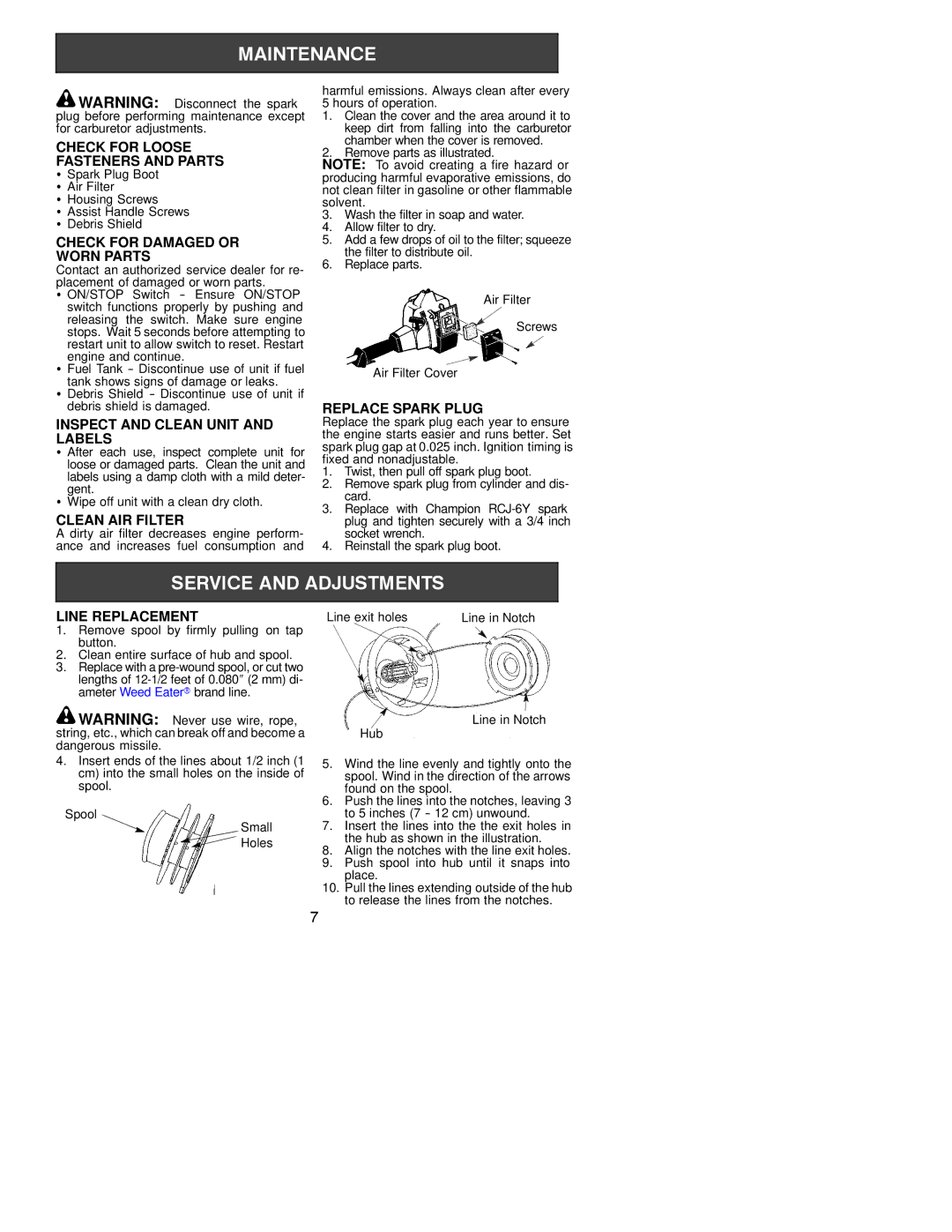

Both models are engineered for durability, featuring rugged construction that withstands the rigors of yard work. They are also designed for easy maintenance, with accessible air filters and spark plug locations that enable effortless servicing.

In summary, the Weed Eater XT250 and FX25 combine power, comfort, and innovative technology, making them excellent choices for anyone seeking to maintain a pristine lawn. Their user-friendly features, coupled with robust performance, ensure that whether you are tackling stubborn weeds or simply tidying up your yard, these trimmers will deliver reliability and efficiency. Perfect for homeowners and light commercial users alike, these models exemplify the commitment to quality that Weed Eater is known for.