WFGA-60FS specifications

The Wells WFGA-60FS is a standout commercial griddle that has been designed to meet the rigorous demands of bustling kitchens. Built to deliver excellent performance, this unit is perfect for breakfast, lunch, and dinner services, making it a versatile option for any food establishment.One of the defining features of the Wells WFGA-60FS is its expansive cooking surface. With a generous 60-inch width, the griddle provides ample space to cook multiple items simultaneously, significantly increasing production capabilities. The smooth, polished steel cooking surface ensures even heat distribution, resulting in perfectly cooked foods every time.

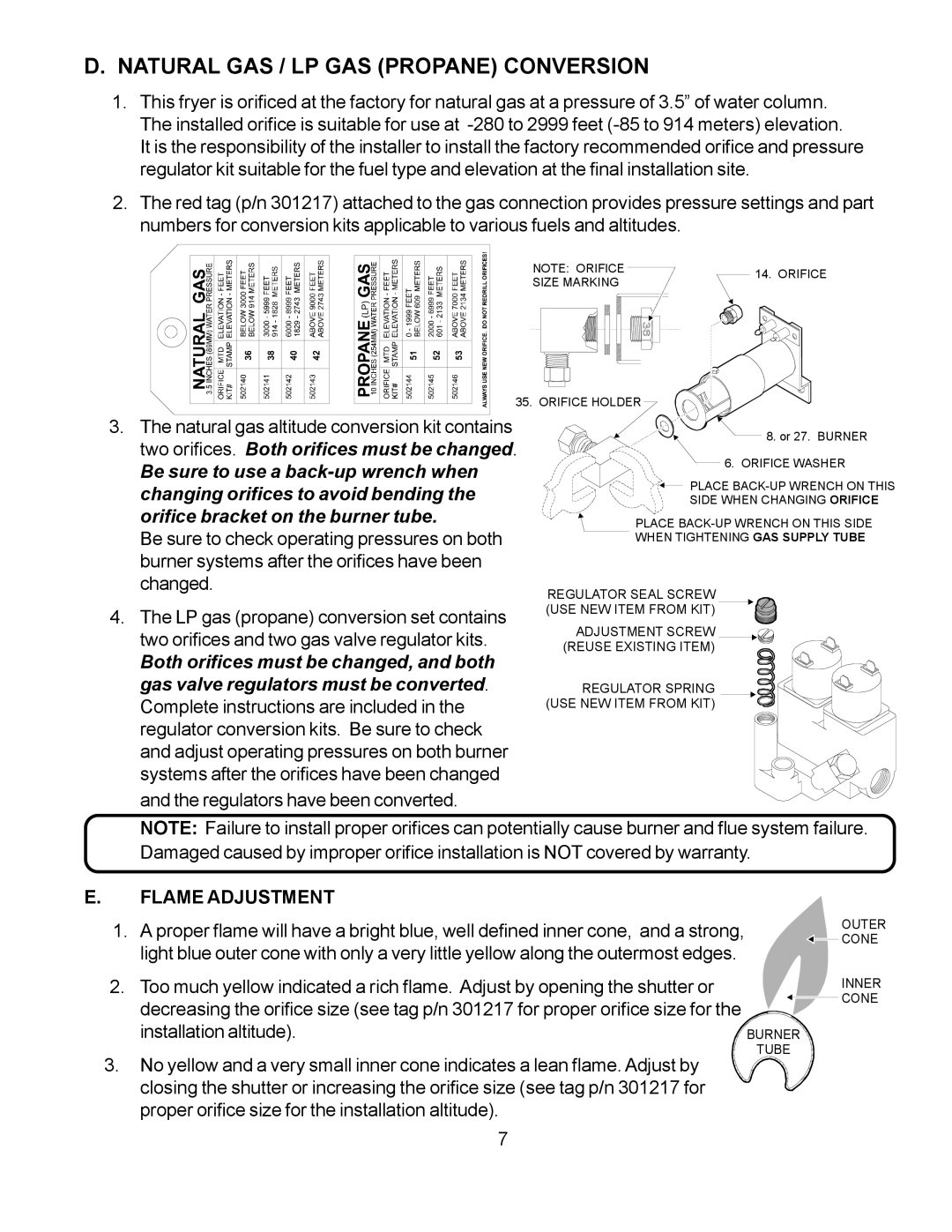

The Wells WFGA-60FS is equipped with a powerful gas system that delivers consistent heat with rapid recovery times. It utilizes high-performance cast iron burners that are designed to withstand heavy use while providing quick and effective heating. The adjustable thermostat allows chefs to maintain precise cooking temperatures, making it an ideal piece of equipment for various cooking techniques, whether it's searing meats, sautéing vegetables, or preparing pancakes.

Safety features are paramount in the design of the WFGA-60FS. It comes with a manual shut-off valve and a flame failure safety device, ensuring that gas supply is cut off if the flame goes out, contributing to a safer kitchen environment. The durable stainless-steel construction not only enhances the aesthetic appeal of the griddle but also ensures long-lasting durability and ease of cleaning.

Another notable characteristic is the grease management system integrated into the Wells WFGA-60FS. The griddle features a built-in grease drain that aids in efficient grease disposal, reducing the risk of flare-ups and promoting a cleaner cooking environment. This design helps maintain hygiene and simplifies the cleaning process after busy service periods.

Moreover, the Wells WFGA-60FS is designed for maximum energy efficiency. The gas consumption rate is optimized to offer high performance while keeping operating costs in check. By combining innovative technologies with user-friendly features, the WFGA-60FS stands as a premium choice for restaurant owners and chefs seeking reliability and efficiency in their kitchen equipment.

In summary, the Wells WFGA-60FS is a powerful and efficient gas griddle that is tailored for high-volume cooking. Its extensive cooking surface, advanced temperature control, safety features, and effective grease management system make it an indispensable tool for any professional kitchen. Whether it’s used in a diner, catering service, or restaurant, the Wells WFGA-60FS proves its worth by elevating culinary capabilities and enhancing the overall cooking experience.