CHECKOPERATION

START-UPANDCHECK-OFF

1.Start the unrt by opening water valve and turning the service switch to “ON ”

2.NOTE: In “CLEAN” positron, only the water pump ooerates

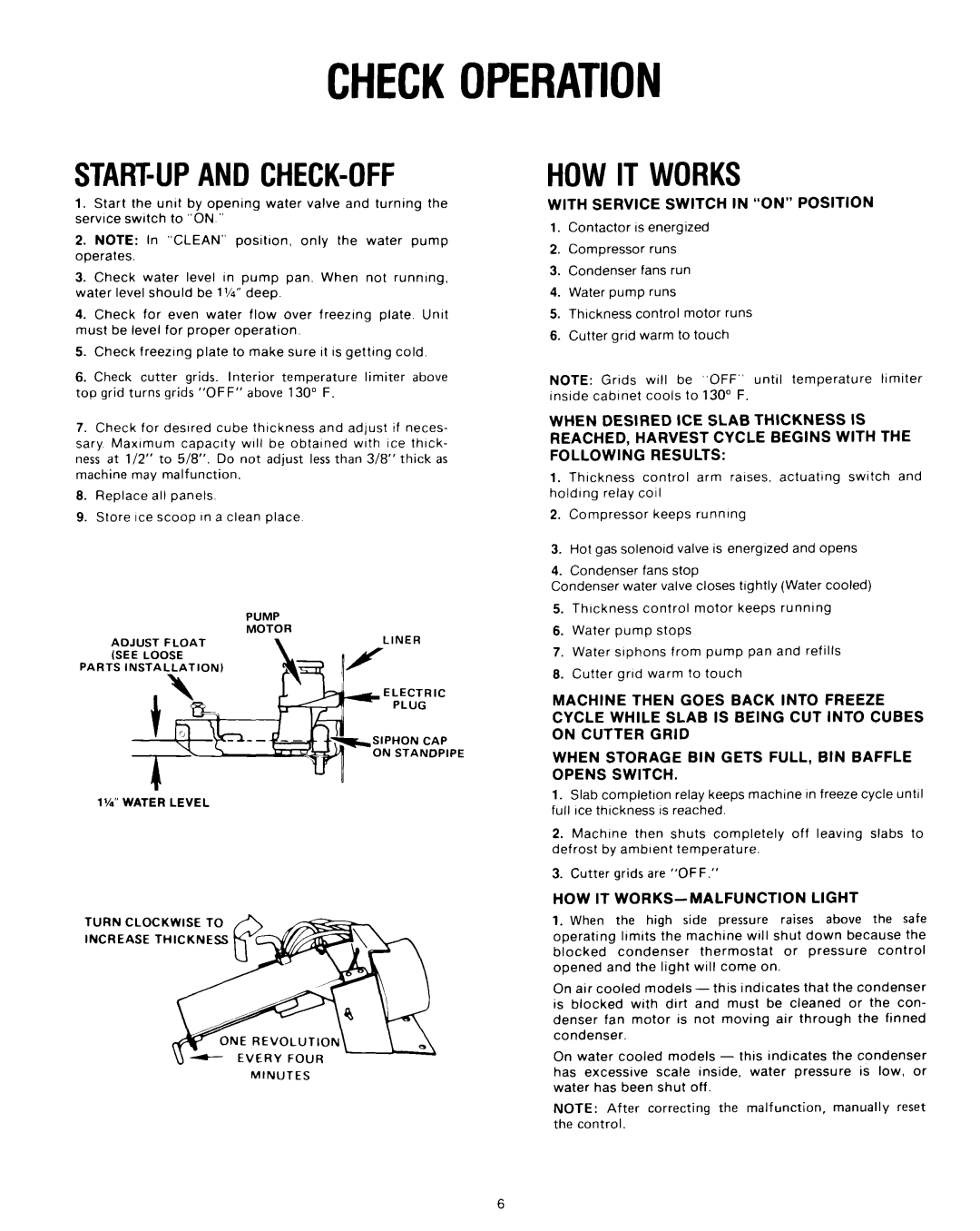

3.Check water level In pump pan. When not running, water level should be 11/4” deep.

4.Check for even water flow over freezrng plate. Unit must be level for proper operation.

5.Check freezrng plate to make sure It IS getting cold.

6.Check cutter grids. Interior temperature limiter above top grid turns grids “OFF” above 130” F.

7.Check for desired cube thrckness and adjust if neces-

sary. Maximum capacity will be obtarned with Ice thrck- ness at l/2” to 5/8”. Do not adjust less than 3/8” thick as machine may malfunction.

8.Replace all panels

9.Store Ice scoop In a clean place.

PUMP

MOTOR

AD | LINER |

(SE

PARTS I

ELECTRIC

PLUG

SIPHON CAP

ON STANDPIPE

1%” WATER LEVEL

TURN CLOCKWISE TO

INCREASE THICKNESS

EVERY FOUR

MINUTES

HOWIT WORKS

WITH SERVICE SWITCH IN “ON” POSITION

1.Contactor IS energized

2.Compressor runs

3.Condenser fans run

4.Water pump runs

5.Thickness control motor runs

6.Cutter grid warm to touch

NOTE: Grids will be “OFF” until temperature limiter inside cabinet cools to 130” F.

WHEN DESIRED ICE SLAB THICKNESS IS REACHED, HARVEST CYCLE BEGINS WITH THE FOLLOWING RESULTS:

1. | Thickness | control | arm raises. | actuating | switch | and | |

holding | relay | co11 |

|

|

|

| |

2. | Compressor | keeps | runnrng |

|

|

| |

3.Hot gas solenord valve is energized and opens

4.Condenser fans stop

Condenser water valve closes tightly (Water cooled)

5. Thickness control motor keeps running

6.Water pump stops

7.Water siphons from pump pan and refills

8.Cutter grid warm to touch

MACHINE THEN GOES BACK INTO FREEZE CYCLE WHILE SLAB IS BEING CUT INTO CUBES ON CUTTER GRID

WHEN STORAGE BIN GETS FULL, BIN BAFFLE OPENS SWITCH.

1.Slab completion relay keeps machine In freeze cycle until full Ice thickness IS reached.

2.Machine then shuts completely off leaving slabs to defrost by ambient temperature.

3.Cutter grids are “OFF.”

HOW IT WORKS-MALFUNCTION LIGHT

1.When the high side pressure raises above the safe

operating lrmits the machine will shut down because the

blocked condenser thermostat or pressure Control opened and the light will come on.

On | air | cooled |

| indicates | that | the | condenser | ||||||||

is | blocked |

| with |

| dirt | and | must | be | cleaned |

| or the | con- | |||

denser | fan | motor | is | not | moving | air | through | the | finned | ||||||

condenser. |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

On | water | cooled |

| models | - | this | indicates | the | condenser | ||||||

has | excessive |

| scale | inside, | water | pressure | is | low, | or | ||||||

water | has | been | shut | off. |

|

|

|

|

|

|

|

| |||

NOTE: After correcting the malfunction, manually reset the control.