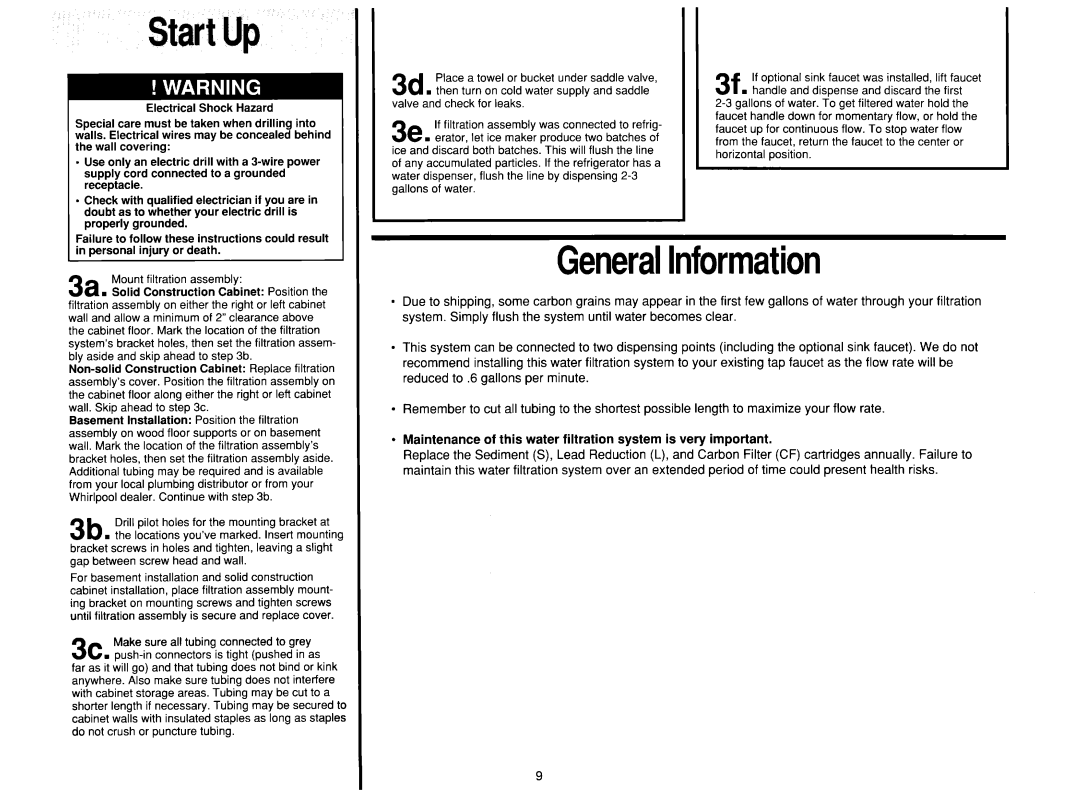

StartUp

Electrical Shock Hazard

Special care must be taken when drilling into walls. Electrical wires may be concealed behind the wall covering:

-Use only an electric drill with a

l Check with qualified electrician if you are in doubt as to whether your electric drill is properly grounded.

3d Place a towel or bucket under saddle valve,

. then turn on cold water supply and saddle valve and check for leaks.

3e If filtration assembly was connected to refrig-

. erator, let ice maker produce two batches of ice and discard both batches. This will flush the line of any accumulated particles. If the refrigerator has a water dispenser, flush the line by dispensing

3f If optional sink faucet was installed, lift faucet

. handle and dispense and discard the first

Failure to follow these instructions could result in personal injury or death.

3a Mount filtration assembly:

. Solid Construction Cabinet: Position the filtration assembly on either the right or left cabinet wall and allow a minimum of 2” clearance above the cabinet floor. Mark the location of the filtration system’s bracket holes, then set the filtration assem- bly aside and skip ahead to step 3b.

Basement Installation: Position the filtration assembly on wood floor supports or on basement wall. Mark the location of the filtration assembly’s bracket holes, then set the filtration assembly aside. Additional tubing may be required and is available from your local plumbing distributor or from your Whirlpool dealer. Continue with step 3b.

3b Drill pilot holes for the mounting bracket at

. the locations you’ve marked. Insert mountin! bracket screws in holes and tighten, leaving a slight gap between screw head and wall.

For basement installation and solid construction cabinet installation, place filtration assembly mount- ing bracket on mounting screws and tighten screws until filtration assembly is secure and replace cover.

3c Make sure all tubing connected to grey

.

GeneralInformation

nDue to shipping, some carbon grains may appear in the first few gallons of water through your filtration system. Simply flush the system until water becomes clear.

lThis system can be connected to two dispensing points (including the optional sink faucet). We do not recommend installing this water filtration system to your existing tap faucet as the flow rate will be reduced to .6 gallons per minute.

lRemember to cut all tubing to the shortest possible length to maximize your flow rate.

lMaintenance of this water filtration system is very important.

Replace the Sediment (S), Lead Reduction (L), and Carbon Filter (CF) cartridges annually. Failure to maintain this water filtration system over an extended period of time could present health risks.

9