TABLE 1: Filter Sizes

Input / Output | CFM (cm/m) | Cabinet | Side (in) | Side (mm) | Bottom (in) | Bottom (mm) | |

BTU/H (kW) | Size | ||||||

|

|

|

|

| |||

|

|

|

|

|

|

| |

40/37 (11.71/10.84) | 1000 (28.32) | 16 x 25 | 406 x 635 | 14 x 25 | 356 x 635 | ||

60/55/ (17.57/16.10) | 1000 (28.32) | 16 x 25 | 406 x 635 | 16 x 25 | 406 x 635 | ||

80/75/ (23.42/21.96) | 1200 (33.98) | 16 x 25 | 406 x 635 | 16 x 25 | 406 x 635 | ||

80/75/ (23.42/21.96) | 1600 (45.31) | 21” (C) | 16 x 25 | 406 x 635 | 20 x 25 | 508 x 635 | |

100/95 (29.28/27.82) | 1400 (39.64) | 21” (C) | 16 x 25 | 406 x 635 | 20 x 25 | 508 x 635 | |

100/95 (29.28/27.82) | 2000 (56.63) | 21” (C) | (2) 16 x 25 | (2) 406 x 635 | 20 x 25 | 508 x 635 | |

120/112/ (35.14/32.80) | 2000 (56.63) | (2) 16 x 25 | (2) 406 x 635 | 22 x 25 | 559 x 635 | ||

140/130/ (40.99/38.06) | 2000 (56.63) | (2) 16 x 25 | (2) 406 x 635 | 22 x 25 | 559 x 635 |

How to Clean your Filter

Blower Care

Even with good filters properly in place, blower wheels and motors will become dust laden after long months of operation. The entire blower assembly should be inspected annually. If the motor and wheel are heavily coated with dust, they can be brushed and cleaned with a vac- uum cleaner. If the blower cannot be properly cleaned without removing it from the furnace, then this service must be performed by a qualified service agency.

Make sure you DO NOT move the clip on weight on the indoor fan wheel when cleaning the wheel. This weight is used to balance the wheel. Moving the weight will cause the fan wheel to vibrate.

Motor Lubrication

The motors in these furnaces are permanently lubricated, and do not require periodic oiling.

SEQUENCE OF OPERATION

The following describes the sequence of operation of the furnace. Refer to Figure 1 for component location.

Continuous Blower

Cooling/heating thermostats have a fan switch that has an ON and AUTO position. In the ON position the thermostat circuit is completed between terminals R and G. The motor will operate on the speed tap wire that is connected to the cooling terminal on the control board. To obtain a constant air circulation at lower flow rate, change the high- speed wire to either the medium speed wire or the low speed wire.

Intermittent Blower - Cooling

Cooling/heating thermostats have a fan switch that has an ON and AUTO position. In the AUTO position the thermostat circuit is completed between terminals R and G when there is a call for cooling. The motor will operate on the speed tap wire that is connected to the cooling termi- nal on the control board. The fan off setting is fixed at 60 seconds for SEER enhancement.

Heating Cycle

When the thermostat switch is set on HEAT and the fan is set on AUTO, and there is a call for heat, a circuit is completed between terminals R and W of the thermostat. When the proper amount of combustion air is being provided, the pressure switch will close, the ignition control pro- vides a

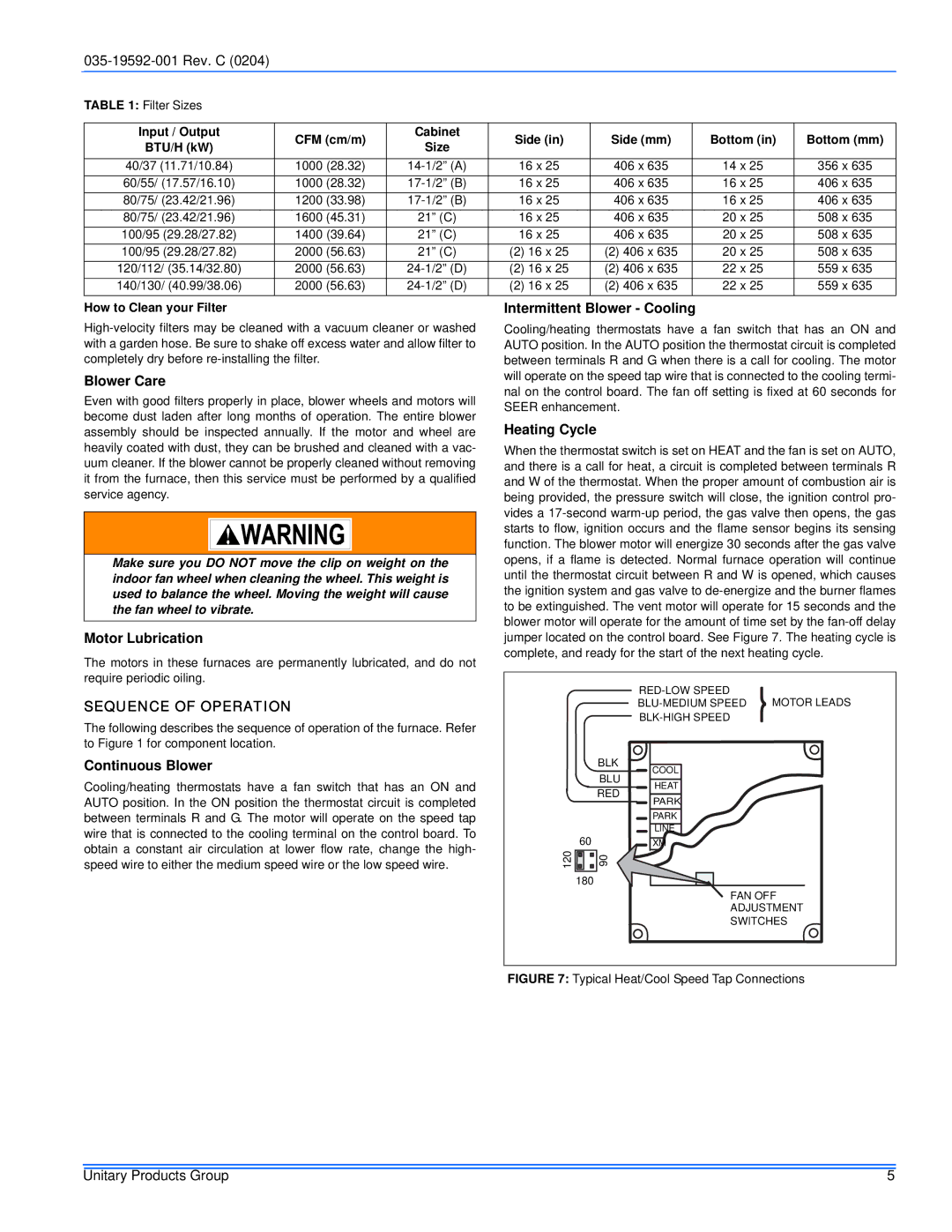

MOTOR LEADS | |

|

BLK

COOL

BLU HEAT

RED

PARK

PARK

LINE

60XM

120 |

| 90 |

| 180 |

|

FAN OFF

ADJUSTMENT

SWITCHES

FIGURE 7: Typical Heat/Cool Speed Tap Connections

Unitary Products Group | 5 |