IV. Operation and Adjustments

NOTE: An Industravac vacuum cleaning system consists of the Industravac unit and its associated components. The vacuum producer is designed for operation under load, hence it must always be connected directly to hose and tools or to a tubing system with hose and tools.

Machine startup

1.Turn the Industravac unit on, having fully completed the previous setup procedures.

2.(For units equipped with discharge air gate.) With a full vacuum system load connected to the separator inlet(s), connect an ammeter to the motor circuit. Measure the draw (amperage) of the motor. If it is below the full load current rating, open the air gate until the amperage reach- es, but does not exceed, the

3.(For units equipped with Electronic Modulating Bleed Control.) Follow adjustment instructions in the separate data sheet accompanying the EMBC.

4.Check the tubing system and vacuum equipment for leaks. At the separator, check the access door, dirt can seal and hose inlet valves. Examine all hoses, tubes, and fittings connected to the Industravac unit. Air leaks are highly detrimental to the overall system perfor- mance, wasting power and impairing the operating efficiency.

CAUTION: When the vacuum producer is operating, its housing will be hot to the touch. Use caution when making inspections or adjustments in this area.

Hose and tools

For optimum performance, Industravac units should be used only with complementary Spencer vacuum cleaning equip- ment system

V. Maintenance

CAUTION: Disconnect electrical power before performing any maintenance procedure.

1. Lubrication

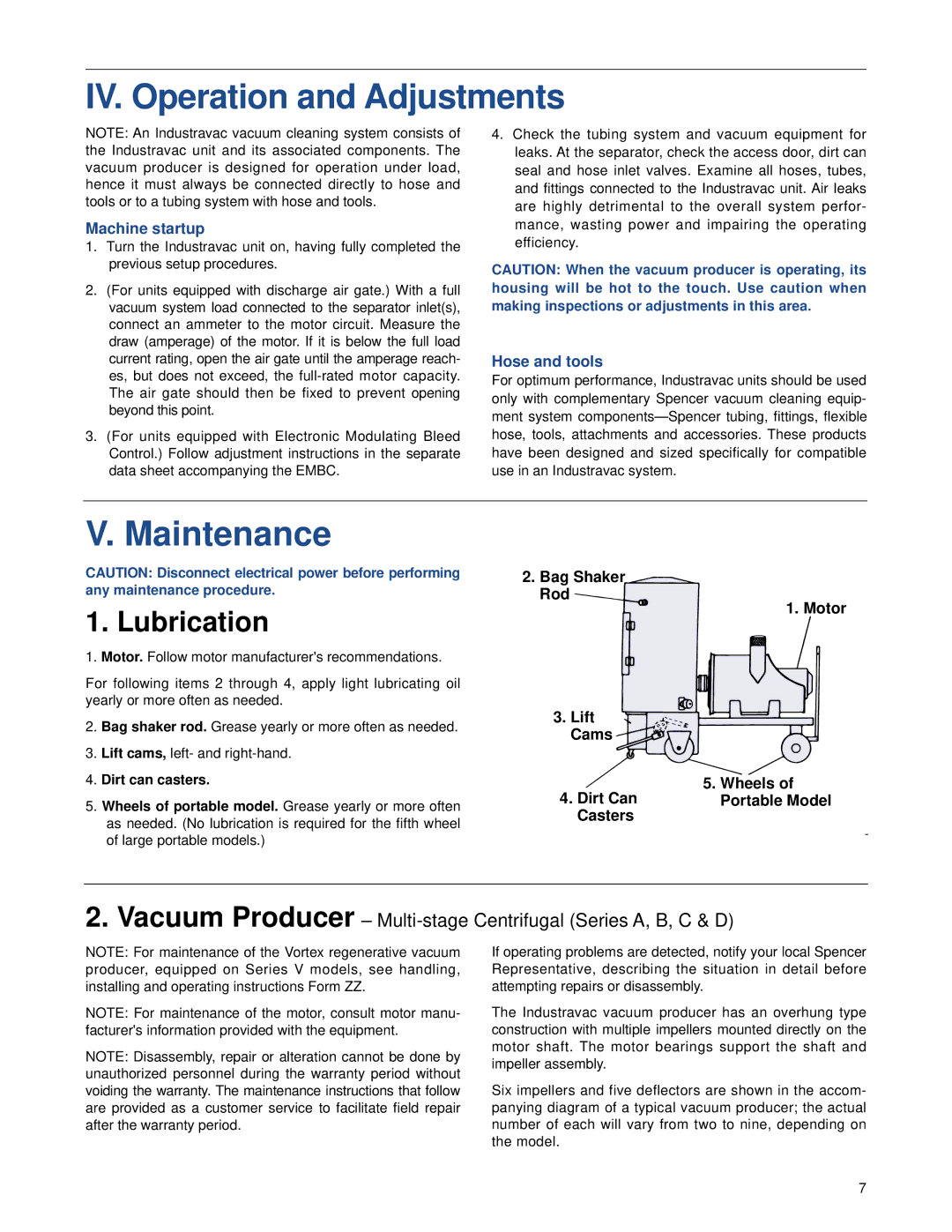

1. Motor. Follow motor manufacturer's recommendations.

For following items 2 through 4, apply light lubricating oil yearly or more often as needed.

2.Bag shaker rod. Grease yearly or more often as needed.

3.Lift cams, left- and

4.Dirt can casters.

5.Wheels of portable model. Grease yearly or more often as needed. (No lubrication is required for the fifth wheel of large portable models.)

2.Bag Shaker Rod

1. Motor

3. Lift

Cams

5. Wheels of

4. Dirt CanPortable Model

Casters

2. Vacuum Producer – Multi-stage Centrifugal (Series A, B, C & D)

NOTE: For maintenance of the Vortex regenerative vacuum producer, equipped on Series V models, see handling, installing and operating instructions Form ZZ.

NOTE: For maintenance of the motor, consult motor manu- facturer's information provided with the equipment.

NOTE: Disassembly, repair or alteration cannot be done by unauthorized personnel during the warranty period without voiding the warranty. The maintenance instructions that follow are provided as a customer service to facilitate field repair after the warranty period.

If operating problems are detected, notify your local Spencer Representative, describing the situation in detail before attempting repairs or disassembly.

The Industravac vacuum producer has an overhung type construction with multiple impellers mounted directly on the motor shaft. The motor bearings support the shaft and impeller assembly.

Six impellers and five deflectors are shown in the accom- panying diagram of a typical vacuum producer; the actual number of each will vary from two to nine, depending on the model.

7