Balancing (For Series V see Form ZZ)

Turn the machine on with inlet blocked to check balance. If there is excess vibration due to an unbalanced condition after reassemble, use the following balancing procedure:

1.Mark the position of the end impeller hub on the shaft.

2.Loosen the bolts or screws holding the impeller on the shaft.

3.Rotate the impeller 90° on the shaft, retighten the bolts or screws.

4.Run the machine again at operating speed and check vibration.

5.Repeat this procedure until the best balance (least vibration) is obtained. If satisfactory results are not achieved, contact the Spencer Service Department for recommendations.

3. Separator

Shaking the Filter Bags

NOTE: The vacuum producer must be turned off during bag shaking, or loosened dirt will immediately redeposit on the filter bags.

Grasp the external bag shaker handle and move it back and forth vigorously for 5 to 10 seconds. This action loosens dirt that has accumulated inside the filter bags, allowing it to fall into the dirt can.

For portable Industravac models, bag shaking should be done after each use; for stationary models, after each shift to maintain optimum vacuum performance.

Emptying the Dirt Can

For new Industravac applications, check the rate of dirt accu- mulation in the dirt can and then establish a regular emptying schedule. If the application characteristics change, modify the schedule to suit. The can should be emptied when it is no more than 3/4 full. Or, for convenience, it can be emptied by weight rather than volume, at any lesser level.

To remove the dirt can, lift the bail arm in front of the separator, lowering the container onto the floor where it can be wheeled away on its casters for emptying. To replace the can, simply push it into place under the separator. A

Changing Door and Dirt Can Gaskets

1.Peel off old gasket.

2.Clean old adhesive off gasket seat.

3.Check replacement gasket for fit; trim if necessary.

4.Coat gasket and seat with rubber cement, apply gasket.

5.Check for airtight seal after cement is dry.

Maintaining the Equalizing Line

Periodically check the equalizing line, if present, to be sure it is clear and free of leaks, If problems occur, replacement kits are available from Spencer.

NOTE: Spencer disposable dirt can liners must always be used if an equalizing line has been installed or mechanical and environmental damage will result.

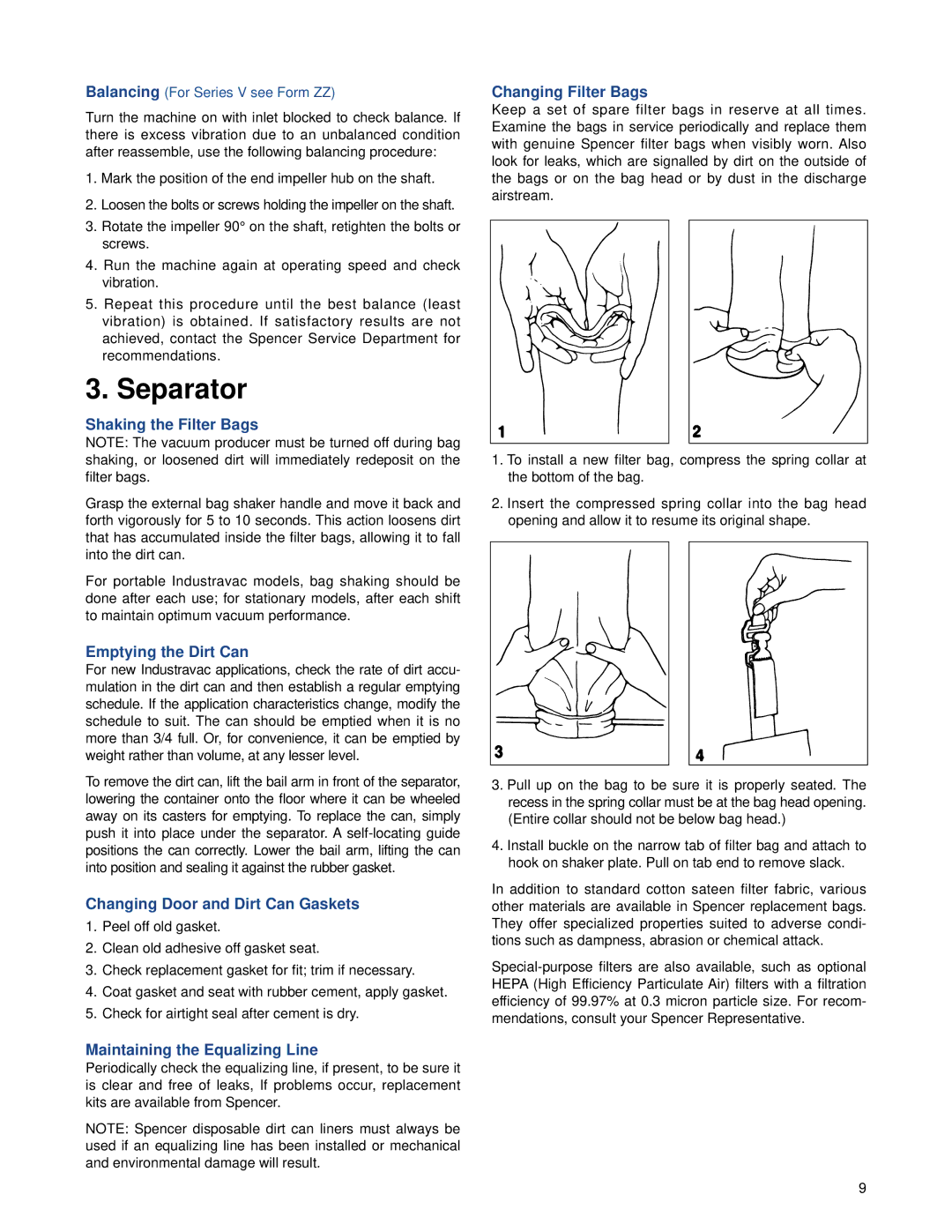

Changing Filter Bags

Keep a set of spare filter bags in reserve at all times. Examine the bags in service periodically and replace them with genuine Spencer filter bags when visibly worn. Also look for leaks, which are signalled by dirt on the outside of the bags or on the bag head or by dust in the discharge airstream.

1.To install a new filter bag, compress the spring collar at the bottom of the bag.

2.Insert the compressed spring collar into the bag head opening and allow it to resume its original shape.

3.Pull up on the bag to be sure it is properly seated. The recess in the spring collar must be at the bag head opening. (Entire collar should not be below bag head.)

4.Install buckle on the narrow tab of filter bag and attach to hook on shaker plate. Pull on tab end to remove slack.

In addition to standard cotton sateen filter fabric, various other materials are available in Spencer replacement bags. They offer specialized properties suited to adverse condi- tions such as dampness, abrasion or chemical attack.

9