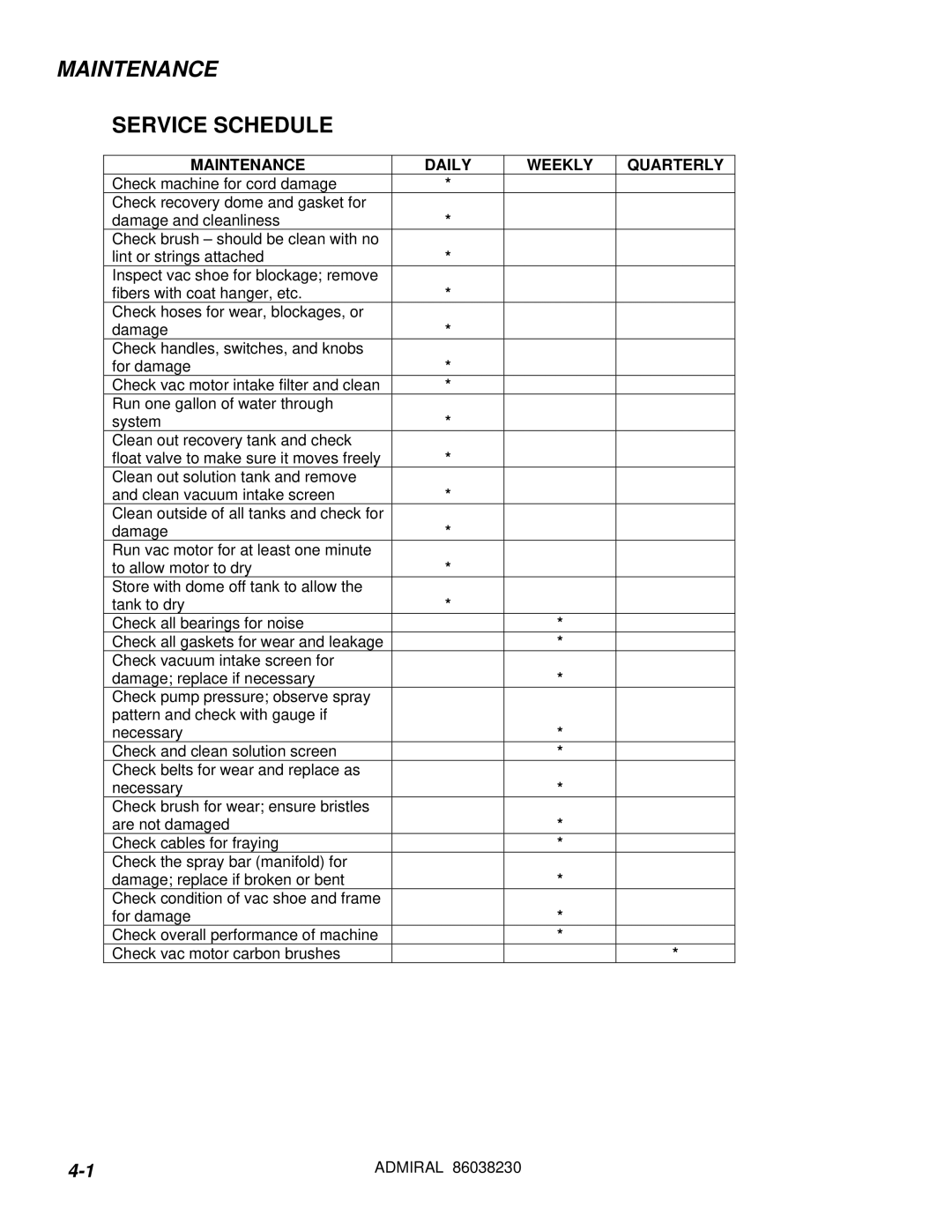

MAINTENANCE

SERVICE SCHEDULE

MAINTENANCE | DAILY | WEEKLY | QUARTERLY |

Check machine for cord damage | * |

|

|

Check recovery dome and gasket for |

|

|

|

damage and cleanliness | * |

|

|

Check brush – should be clean with no |

|

|

|

lint or strings attached | * |

|

|

Inspect vac shoe for blockage; remove |

|

|

|

fibers with coat hanger, etc. | * |

|

|

Check hoses for wear, blockages, or |

|

|

|

damage | * |

|

|

Check handles, switches, and knobs |

|

|

|

for damage | * |

|

|

Check vac motor intake filter and clean | * |

|

|

Run one gallon of water through |

|

|

|

system | * |

|

|

Clean out recovery tank and check |

|

|

|

float valve to make sure it moves freely | * |

|

|

Clean out solution tank and remove |

|

|

|

and clean vacuum intake screen | * |

|

|

Clean outside of all tanks and check for |

|

|

|

damage | * |

|

|

Run vac motor for at least one minute |

|

|

|

to allow motor to dry | * |

|

|

Store with dome off tank to allow the |

|

|

|

tank to dry | * |

|

|

Check all bearings for noise |

| * |

|

Check all gaskets for wear and leakage |

| * |

|

Check vacuum intake screen for |

|

|

|

damage; replace if necessary |

| * |

|

Check pump pressure; observe spray |

|

|

|

pattern and check with gauge if |

|

|

|

necessary |

| * |

|

Check and clean solution screen |

| * |

|

Check belts for wear and replace as |

|

|

|

necessary |

| * |

|

Check brush for wear; ensure bristles |

|

|

|

are not damaged |

| * |

|

Check cables for fraying |

| * |

|

Check the spray bar (manifold) for |

|

|

|

damage; replace if broken or bent |

| * |

|

Check condition of vac shoe and frame |

|

|

|

for damage |

| * |

|

Check overall performance of machine |

| * |

|

Check vac motor carbon brushes |

|

| * |

ADMIRAL 86038230 |