8.Attach quick couplers to tractor hydraulic source.

9.Place jack stand in storage position.

OPERATING TECHNIQUE

1.Power for operating the stump grinder is supplied by the tractor PTO. Know how to stop the tractor and stump grinder quickly in an emergency.

2.Position stump grinder above stump to be removed. Engage PTO at low engine rpm to minimize stress on the drive system and gearbox. With PTO engaged, increase PTO speed to 540 rpm and maintain throughout grinding operation.

3.Lower tractor

4.Activate top cylinder to lower the cutting wheel onto the stump to desired depth.

NOTE: The amount of material removed may vary depending on tractor size and hardness of wood.

5.Start cutting wheel on left edge of stump and slowly activate side cylinder to begin grinding. Cutting wheel can pivot

6.With pass across stump completed, activate side cylinder to the left, lower top cylinder to remove more material, and activate side cylinder to the right. Continue this process until stump is removed.

NOTE: If stump is too large to remove in one pass, reposition tractor and start operating procedures over.

NOTICE

■Top cylinder must be completely raised to avoid driveline damage before raising

When finished grinding stump, disengage PTO, raise top cylinder, and raise stump grinder off the ground with the

STORE STUMP GRINDER

1.Raise stump grinder with

2.Remove lynch pin from jack stand.

3.Lower jack stand and align top hole in jack stand tube with hole in jack stand support bracket.

4.Insert lynch pin to secure jack stand into position.

5.Lower stump grinder with

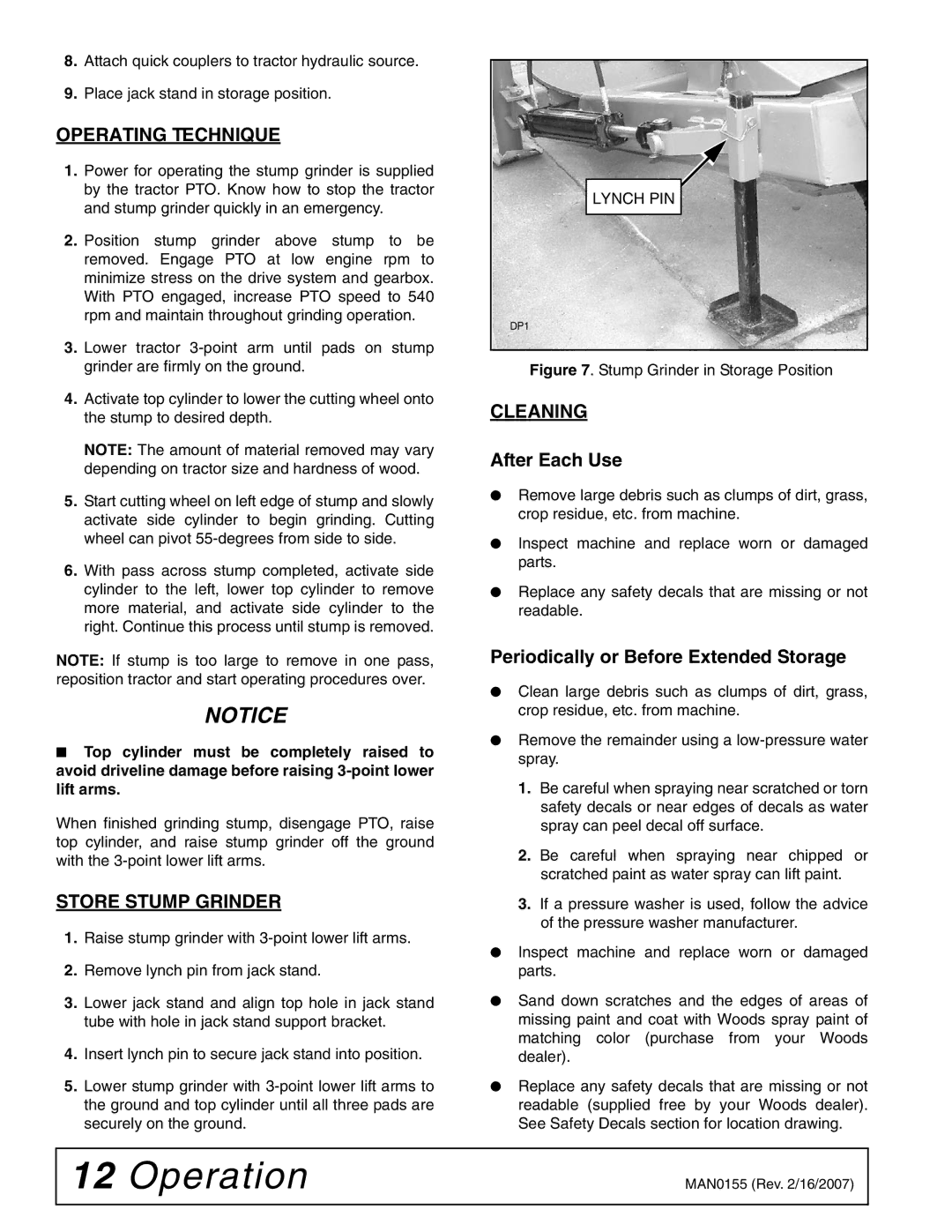

LYNCH PIN

DP1

Figure 7. Stump Grinder in Storage Position

CLEANING

After Each Use

●Remove large debris such as clumps of dirt, grass, crop residue, etc. from machine.

●Inspect machine and replace worn or damaged parts.

●Replace any safety decals that are missing or not readable.

Periodically or Before Extended Storage

●Clean large debris such as clumps of dirt, grass, crop residue, etc. from machine.

●Remove the remainder using a

1.Be careful when spraying near scratched or torn safety decals or near edges of decals as water spray can peel decal off surface.

2.Be careful when spraying near chipped or scratched paint as water spray can lift paint.

3.If a pressure washer is used, follow the advice of the pressure washer manufacturer.

●Inspect machine and replace worn or damaged parts.

●Sand down scratches and the edges of areas of missing paint and coat with Woods spray paint of matching color (purchase from your Woods dealer).

●Replace any safety decals that are missing or not readable (supplied free by your Woods dealer). See Safety Decals section for location drawing.

12 Operation | MAN0155 (Rev. 2/16/2007) |

|

|