ADJUSTING SLIP CLUTCH | 4. Hold | clutch support (19) solid and turn shaft to | |||

The slip clutch is designed to slip so that the gearbox | make sure clutch slips. | ||||

5. If clutch does not slip freely, disassemble and clean | |||||

and driveline are protected if the cutter strikes an | |||||

the inner clutch plate faces (21), flange yoke (17), | |||||

obstruction. | |||||

and clutch support (19). | |||||

A new slip clutch or one that has been in storage over | |||||

6. Reassemble clutch. | |||||

the winter may seize. Before operating the grinder, | |||||

|

|

| |||

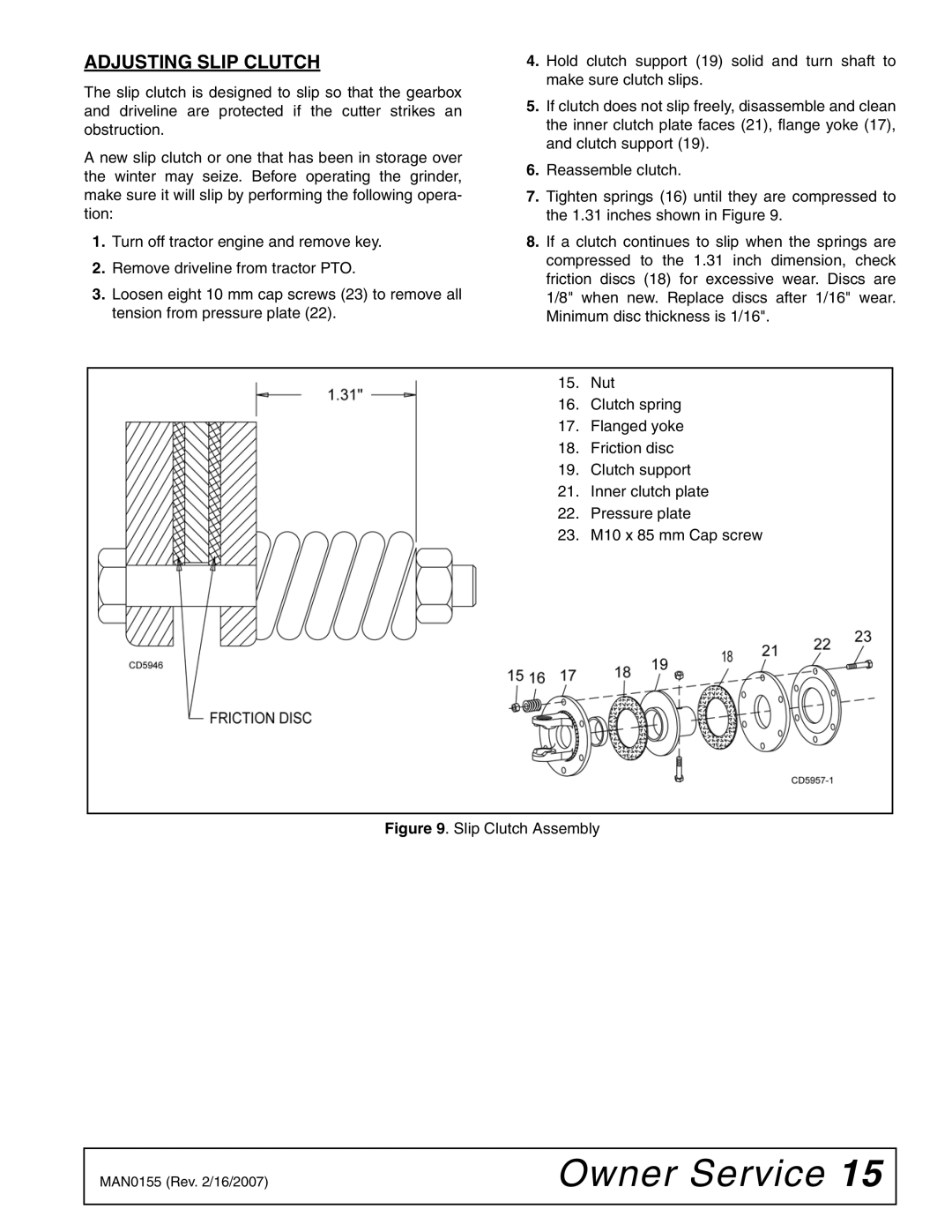

make sure it will slip by performing the following opera- | 7. Tighten springs (16) until they are compressed to | ||||

tion: | the 1.31 inches shown in Figure 9. | ||||

| 1. Turn off tractor engine and remove key. | 8. If a clutch continues to slip when the springs are | |||

| 2. Remove driveline from tractor PTO. | compressed to the 1.31 inch dimension, check | |||

| friction discs (18) for excessive wear. Discs are | ||||

| 3. Loosen eight 10 mm cap screws (23) to remove all | ||||

| 1/8" when new. Replace discs after 1/16" wear. | ||||

| tension from pressure plate (22). | Minimum disc thickness is 1/16". | |||

|

|

|

|

| |

|

| 15. | Nut |

| |

|

| 16. | Clutch spring |

| |

|

| 17. | Flanged yoke |

| |

|

| 18. | Friction disc |

| |

|

| 19. | Clutch support |

| |

|

| 21. | Inner clutch plate |

| |

|

| 22. | Pressure plate |

| |

|

| 23. | M10 x 85 mm Cap screw |

| |

|

|

|

|

| |

Figure 9. Slip Clutch Assembly

MAN0155 (Rev. 2/16/2007) | Owner Service 15 |

|

|