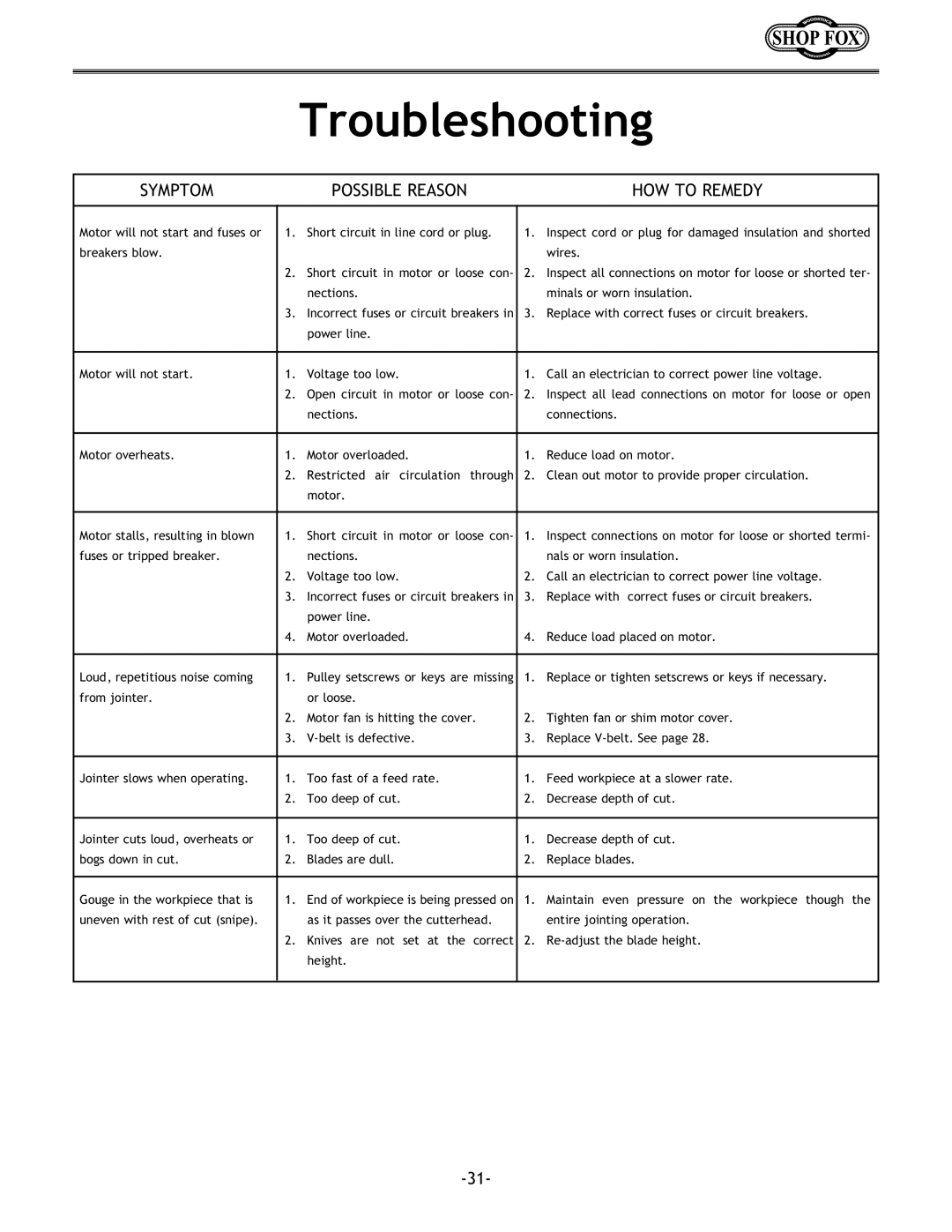

Troubleshooting

|

|

|

|

|

|

|

|

|

| SYMPTOM |

|

| POSSIBLE REASON |

|

| HOW TO REMEDY |

|

|

|

|

|

|

|

|

|

|

| Motor will not start and fuses or |

| 1. | Short circuit in line cord or plug. |

| 1. | Inspect cord or plug for damaged insulation and shorted |

|

| breakers blow. |

|

|

|

|

| wires. |

|

|

|

| 2. | Short circuit in motor or loose con- |

| 2. | Inspect all connections on motor for loose or shorted ter- |

|

|

|

|

| nections. |

|

| minals or worn insulation. |

|

|

|

| 3. | Incorrect fuses or circuit breakers in |

| 3. | Replace with correct fuses or circuit breakers. |

|

|

|

|

| power line. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Motor will not start. |

| 1. | Voltage too low. |

| 1. | Call an electrician to correct power line voltage. |

|

|

|

| 2. | Open circuit in motor or loose con- |

| 2. | Inspect all lead connections on motor for loose or open |

|

|

|

|

| nections. |

|

| connections. |

|

|

|

|

|

|

|

|

|

|

| Motor overheats. |

| 1. | Motor overloaded. |

| 1. | Reduce load on motor. |

|

|

|

| 2. | Restricted air circulation through |

| 2. | Clean out motor to provide proper circulation. |

|

|

|

|

| motor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Motor stalls, resulting in blown |

| 1. | Short circuit in motor or loose con- |

| 1. | Inspect connections on motor for loose or shorted termi- |

|

| fuses or tripped breaker. |

|

| nections. |

|

| nals or worn insulation. |

|

|

|

| 2. | Voltage too low. |

| 2. | Call an electrician to correct power line voltage. |

|

|

|

| 3. | Incorrect fuses or circuit breakers in |

| 3. | Replace with correct fuses or circuit breakers. |

|

|

|

|

| power line. |

|

|

|

|

|

|

| 4. | Motor overloaded. |

| 4. | Reduce load placed on motor. |

|

|

|

|

|

|

|

|

|

|

| Loud, repetitious noise coming |

| 1. | Pulley setscrews or keys are missing |

| 1. | Replace or tighten setscrews or keys if necessary. |

|

| from jointer. |

|

| or loose. |

|

|

|

|

|

|

| 2. | Motor fan is hitting the cover. |

| 2. | Tighten fan or shim motor cover. |

|

|

|

| 3. |

| 3. | Replace |

| |

|

|

|

|

|

|

|

|

|

| Jointer slows when operating. |

| 1. | Too fast of a feed rate. |

| 1. | Feed workpiece at a slower rate. |

|

|

|

| 2. | Too deep of cut. |

| 2. | Decrease depth of cut. |

|

|

|

|

|

|

|

|

|

|

| Jointer cuts loud, overheats or |

| 1. | Too deep of cut. |

| 1. | Decrease depth of cut. |

|

| bogs down in cut. |

| 2. | Blades are dull. |

| 2. | Replace blades. |

|

|

|

|

|

|

|

|

|

|

| Gouge in the workpiece that is |

| 1. | End of workpiece is being pressed on |

| 1. | Maintain even pressure on the workpiece though the |

|

| uneven with rest of cut (snipe). |

|

| as it passes over the cutterhead. |

|

| entire jointing operation. |

|

|

|

| 2. | Knives are not set at the correct |

| 2. |

| |

|

|

|

| height. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|