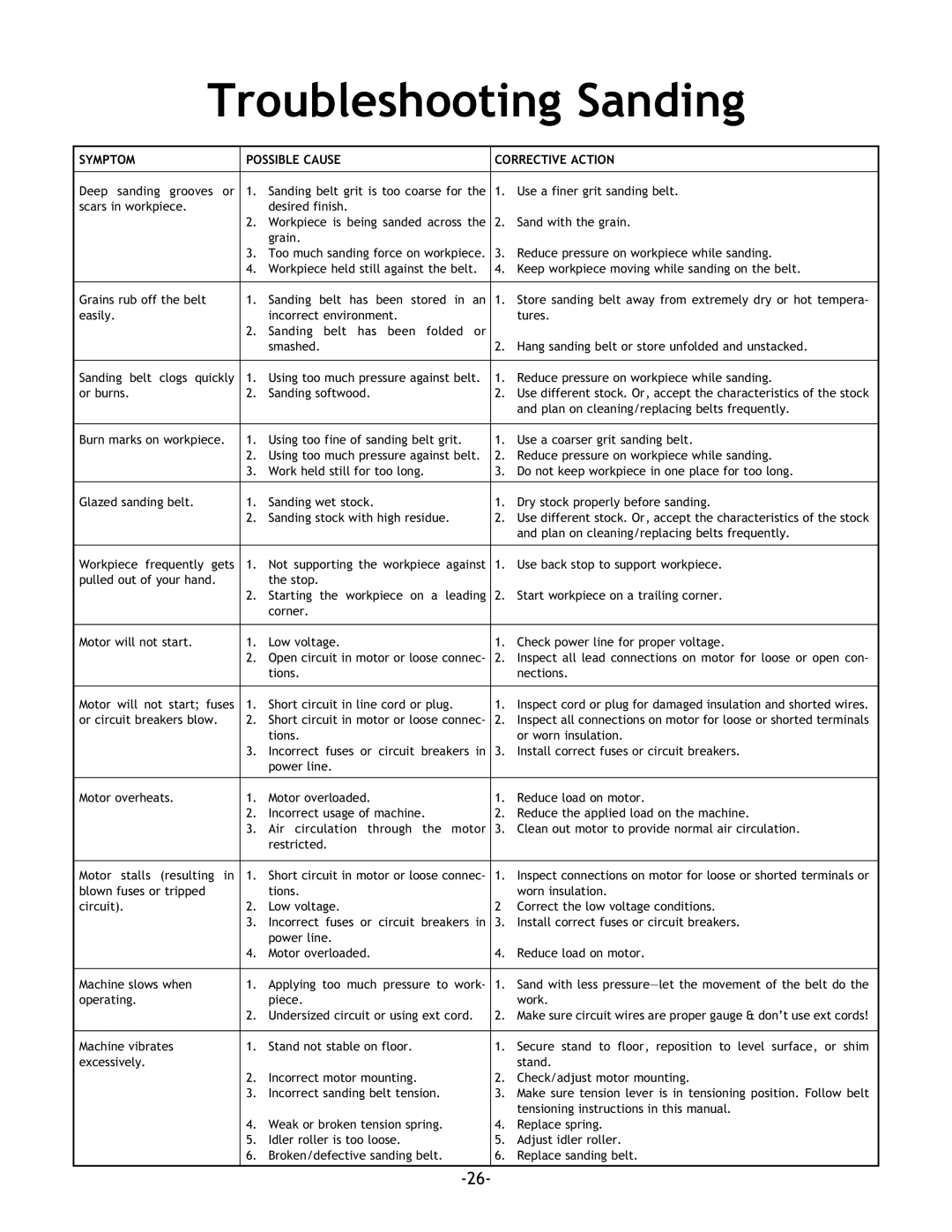

Troubleshooting Sanding

SYMPTOM |

| POSSIBLE CAUSE | CORRECTIVE ACTION |

|

| ||

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Deep sanding grooves | or | 1. | Sanding belt grit is too coarse for the | 1. | Use a finer grit sanding belt. | ||

scars in workpiece. |

|

| desired finish. |

|

|

|

|

|

| 2. | Workpiece is being sanded across the | 2. | Sand with the grain. | ||

|

|

| grain. |

|

|

|

|

|

| 3. | Too much sanding force on workpiece. | 3. | Reduce pressure on workpiece while sanding. | ||

|

| 4. | Workpiece held still against the belt. | 4. | Keep workpiece moving while sanding on the belt. | ||

|

|

|

|

|

|

|

|

Grains rub off the belt |

| 1. | Sanding belt has been stored in an | 1. | Store sanding belt away from extremely dry or hot tempera- | ||

easily. |

|

| incorrect environment. |

| tures. | ||

|

| 2. | Sanding belt has been folded or |

|

|

|

|

|

|

| smashed. | 2. | Hang sanding belt or store unfolded and unstacked. | ||

|

|

|

|

|

|

| |

Sanding belt clogs quickly | 1. | Using too much pressure against belt. | 1. | Reduce pressure on workpiece while sanding. | |||

or burns. |

| 2. | Sanding softwood. | 2. | Use different stock. Or, accept the characteristics of the stock | ||

|

|

|

|

| and plan on cleaning/replacing belts frequently. | ||

|

|

|

|

|

|

| |

Burn marks on workpiece. | 1. | Using too fine of sanding belt grit. | 1. | Use a coarser grit sanding belt. | |||

|

| 2. | Using too much pressure against belt. | 2. | Reduce pressure on workpiece while sanding. | ||

|

| 3. | Work held still for too long. | 3. | Do not keep workpiece in one place for too long. | ||

|

|

|

|

|

|

|

|

Glazed sanding belt. |

| 1. | Sanding wet stock. | 1. | Dry stock properly before sanding. | ||

|

| 2. | Sanding stock with high residue. | 2. | Use different stock. Or, accept the characteristics of the stock | ||

|

|

|

|

| and plan on cleaning/replacing belts frequently. | ||

|

|

|

|

|

|

| |

Workpiece frequently gets | 1. | Not supporting the workpiece against | 1. | Use back stop to support workpiece. | |||

pulled out of your hand. |

|

| the stop. |

|

|

|

|

|

| 2. | Starting the workpiece on a leading | 2. | Start workpiece on a trailing corner. | ||

|

|

| corner. |

|

|

|

|

|

|

|

|

|

|

|

|

Motor will not start. |

| 1. | Low voltage. | 1. | Check power line for proper voltage. | ||

|

| 2. | Open circuit in motor or loose connec- | 2. | Inspect all lead connections on motor for loose or open con- | ||

|

|

| tions. |

| nections. | ||

|

|

|

|

|

|

| |

Motor will not start; fuses | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and shorted wires. | |||

or circuit breakers blow. |

| 2. | Short circuit in motor or loose connec- | 2. | Inspect all connections on motor for loose or shorted terminals | ||

|

|

| tions. |

| or worn insulation. | ||

|

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. | ||

|

|

| power line. |

|

|

|

|

|

|

|

|

|

|

|

|

Motor overheats. |

| 1. | Motor overloaded. | 1. | Reduce load on motor. | ||

|

| 2. | Incorrect usage of machine. | 2. | Reduce the applied load on the machine. | ||

|

| 3. | Air circulation through the motor | 3. | Clean out motor to provide normal air circulation. | ||

|

|

| restricted. |

|

|

|

|

|

|

|

|

|

|

|

|

Motor stalls (resulting | in | 1. | Short circuit in motor or loose connec- | 1. | Inspect connections on motor for loose or shorted terminals or | ||

blown fuses or tripped |

|

| tions. |

| worn insulation. | ||

circuit). |

| 2. | Low voltage. | 2 | Correct the low voltage conditions. | ||

|

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. | ||

|

|

| power line. |

|

|

|

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. | ||

|

|

|

|

|

|

|

|

Machine slows when |

| 1. | Applying too much pressure to work- | 1. | Sand with less | ||

operating. |

|

| piece. |

| work. | ||

|

| 2. | Undersized circuit or using ext cord. | 2. | Make sure circuit wires are proper gauge & don’t use ext cords! | ||

|

|

|

|

|

|

|

|

Machine vibrates |

| 1. | Stand not stable on floor. | 1. | Secure stand to floor, reposition to level surface, or shim | ||

excessively. |

|

|

|

| stand. | ||

|

| 2. | Incorrect motor mounting. | 2. | Check/adjust motor mounting. | ||

|

| 3. | Incorrect sanding belt tension. | 3. | Make sure tension lever is in tensioning position. Follow belt | ||

|

|

|

|

| tensioning instructions in this manual. | ||

|

| 4. | Weak or broken tension spring. | 4. | Replace spring. | ||

|

| 5. | Idler roller is too loose. | 5. | Adjust idler roller. | ||

|

| 6. | Broken/defective sanding belt. | 6. | Replace sanding belt. | ||

|

|

|

|

|

|

|

|