Table SAW with Riving Knife

Inventory Differences

Important Changes to Assembly

Blade Requirements

Blade Installation

Blade Size Requirements

Guard

Blade Guard

Spreader

Location to secure blade guard Screw

Installing Blade Guard & Spreader

To remove the pawls, do these steps

Anti-Kickback Pawls

When Not to Use the Blade Guard

When to Use the Blade Guard

Riving Knife

Installing Riving Knife

When to Use the Riving Knife

When Not to Use the Riving Knife

Checking Alignment

Spreader or Riving Knife Alignment

Tools Needed

Follow Checking Alignment, Steps 1-4, on

Adjusting Alignment

Adjusting Bent Spreader/Riving Knife

Possible Tools Needed

D3697-Standard Zero-Clearance Insert

Optional Table Insert

Description

New Parts

=\�FjVain�BVXcZh�VcY�Iddah

Page

Contents

Woodstock Technical Support

Introduction

Introduction

Introduction

Controls and Features

Standard Safety Instructions

Safety

Always Lock Mobile Bases if Used Before Operating Machinery

Additional Safety for Table Saws

Below are tips to avoid the most common causes of kickback

Preventing Kickback

Protecting Yourself from Kickback

Do not stand directly behind Blade when making a cut

Common Terms

W1761 Electrical Specifications

W1761 220V Single-Phase Operation

Extension Cords

Electrical Specifications

W1762 220V 3-Phase Operation

W1762 440V 3-Phase Operation

Phase Converter

Immediately discard all Plastic bags and pack

Items Needed for Set Up

Unpacking

Description Qty

Box Inventory Figure

Inventory

Machine Inventory

Fence Inventory

Extension Table Inventory

Fence Rail Inventory

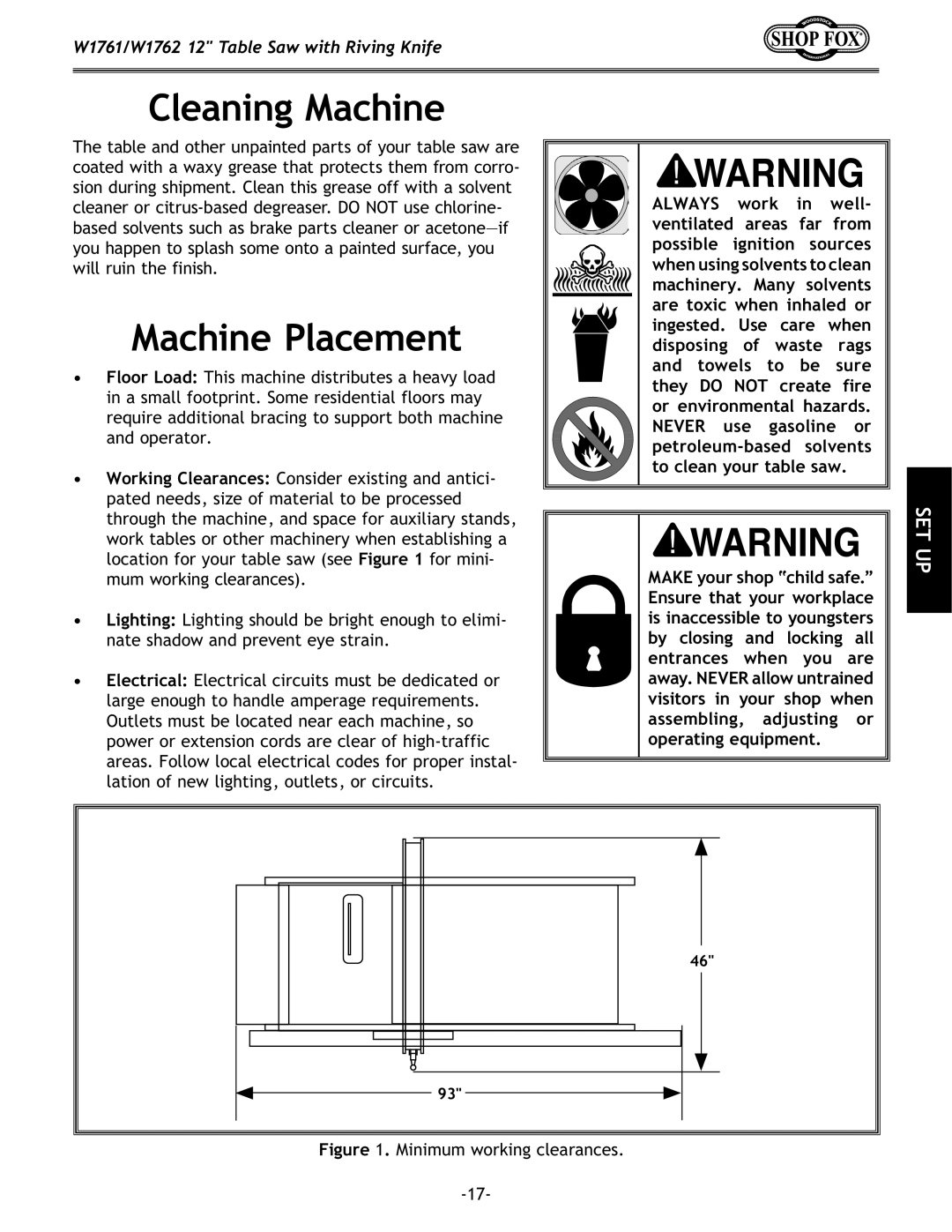

Machine Placement

Cleaning Machine

Extension Table

To install the front and rear rails, do these steps

Leveling main extension table Support Leg Hex Nut Foot

Support leg fastened to main Extension table

To change the arbor, do these steps

To install the blade, do these steps

Saw Blade

Arbor

Blade Guard & Splitter

To install and adjust the table insert, do these steps

To install the blade guard, do these steps

Table Insert

Splitter

To install the riving knife, do these steps

Miter Gauge

ON/OFF Switch

To install the switch, do these steps

To install the miter gauge, do these steps

Recommended CFM at Dust Port

Recommended Adjustments

Recommended adjustment checklist

Dust Collection

To test run the machine, do these steps

Test Run

Basic Controls

General

Blade Selection

Disabling On/Off Switch

Ripping blade features see Figure

Crosscut blade features see Figure

Laminate blade features see Figure

Combination blade features see Figure

Dado Blades see Figure

Through Cuts

Workpiece Inspection

Non-Through Through Cuts

Non-Through Cuts

Typical ripping operation

Ripping

Crosscutting

To make a crosscut using the miter gauge, do these steps

Blade Tilt & Bevel Cuts

Miter Cuts

To perform a miter cut, do these steps

To use a stacked or wobble dado blade, do these steps

Dado Cutting

Disconnect the SAW from Power

To cut rabbets with the dado blade, do these steps

Rabbet Cutting

First cut to create a rabbet With a standard blade

To cut rabbets with the standard blade, do these steps

Resaw Barrier

Resawing

To build the auxiliary fence, do these steps

Auxiliary Fence

To perform resawing operations, do these steps

Resawing Operations

Table Saw Accessories

D3585 Bore General Purpose D3586 Fine Finishing D3587 100

Operations

Weekly Check

Cleaning

Lubrication

Daily Check

Motor & Electrical

Troubleshooting

W1761/W1762 12 Table Saw with Riving Knife

Operations

To remove the flat belt, do these steps

Replacing Flat Belt

Deflect it no more than 1⁄8

To install the new belt, do these steps

To set the 90 stop bolt, do these steps

Blade Tilt Stops

To set the 45 stop bolt, do these steps

Digital Readout

To adjust the tilt indicator arrow, do these steps

To set the digital readout, do these steps

Miter Slot to Blade Parallelism

Example of adjusting blade to Miter slot

Blade Alignment

To adjust the blade by moving the table, do these steps

Square and Height

Adjusting Fence

Clamping Pressure and Parallelism

Miter gauge diagram

W1761 magnetic switch

Switch

See Figure

W1761 Wiring Diagram

W1762 Electrical Components

W1762 magnetic switch prewired to 220V, 3-phase

W1762 Wiring Diagram 220V, 3-Phase

W1762 Wiring Diagram 440V, 3-Phase

Parts

Blade Guard Assembly Blade Guard Assembly Parts List

Fence Assembly Fence Assembly Parts List

Miter Gauge Assembly Miter Gauge Parts List

Main Table, Motor & Cabinet

Motoraccesscover

Main Table, Motor & Cabinet Parts List

Mitergaugemountingbracket

Extension Table Assembly Extension Table Parts List

Label Placement

Warranty

Page

Page

Comments

Warranty Registration

BOX BELLINGHAM, WA