Model W1775 Nailer/Stapler Kit

2. To test for proper nail penetration, |

| — If the nail/staple either went too |

| ||||||||

hold the nailer/stapler perpendicular |

| far or not far enough, then go to |

| ||||||||

to the surface of a piece of clean |

| the Adjusting Depth section on |

| ||||||||

scrap wood that is thick enough for |

| this page. |

| ||||||||

the length of nails/staples you have |

| Adjusting Depth |

| ||||||||

loaded. |

|

| |||||||||

|

|

|

|

|

|

|

|

| |||

3. Depress the safety nose mechanism |

| A depth adjustment knob is attached |

| ||||||||

against your workpiece. |

| to the nose for setting the nail/staple |

| ||||||||

4. Before pulling the trigger, make sure |

| depth. |

| ||||||||

|

|

|

|

|

|

|

|

| |||

your free hand and other body parts |

| To adjust the depth, do these steps: |

| ||||||||

are positioned out of the way of a |

|

|

|

|

|

|

|

|

| ||

potential path of a nail/staple in case |

| 1. DISCONNECT NAILER/STAPLER FROM |

| ||||||||

of deflection. |

| THE AIR SUPPLY! |

| ||||||||

Deflection is caused when grain |

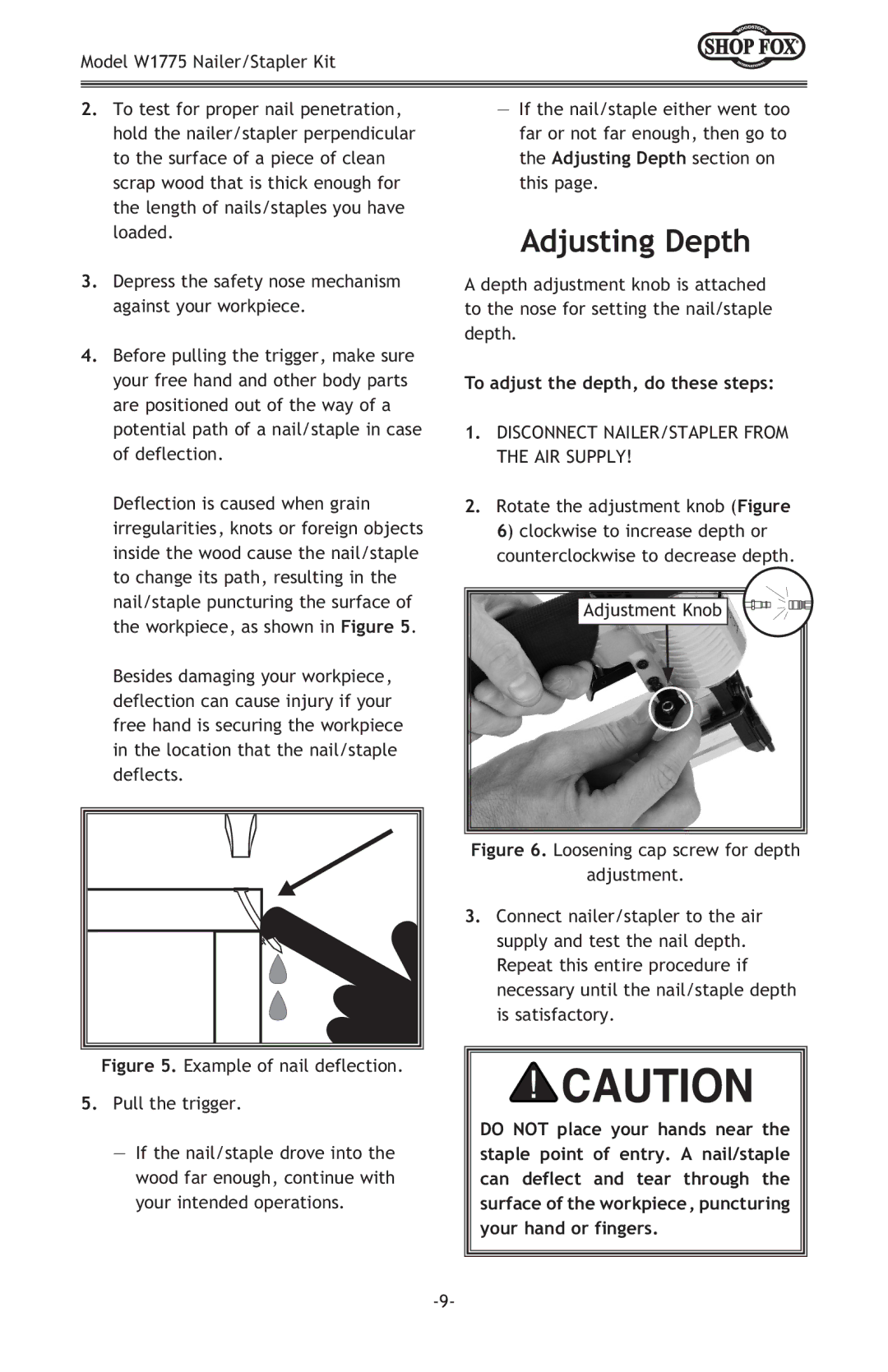

| 2. Rotate the adjustment knob (Figure |

| ||||||||

irregularities, knots or foreign objects |

| 6) clockwise to increase depth or |

| ||||||||

inside the wood cause the nail/staple |

| counterclockwise to decrease depth. |

| ||||||||

to change its path, resulting in the |

|

|

|

|

|

|

|

|

| ||

nail/staple puncturing the surface of |

|

|

|

|

|

|

|

|

| ||

the workpiece, as shown in Figure 5. |

|

| Adjustment Knob |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |||

Besides damaging your workpiece, |

|

|

|

|

|

|

|

|

| ||

deflection can cause injury if your |

|

|

|

|

|

|

|

|

| ||

free hand is securing the workpiece |

|

|

|

|

|

|

|

|

| ||

in the location that the nail/staple |

|

|

|

|

|

|

|

|

| ||

deflects. |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Figure 6. Loosening cap screw for depth |

| ||||||

|

|

|

|

| adjustment. |

| |||||

|

|

|

| 3. Connect nailer/stapler to the air |

| ||||||

|

|

|

| supply and test the nail depth. |

| ||||||

|

|

|

| Repeat this entire procedure if |

| ||||||

|

|

|

| necessary until the nail/staple depth |

| ||||||

|

|

|

| is satisfactory. |

| ||||||

Figure 5. Example of nail deflection. |

|

|

5. Pull the trigger. |

|

|

|

| DO NOT place your hands near the |

— If the nail/staple drove into the |

| staple point of entry. A nail/staple |

wood far enough, continue with |

| can deflect and tear through the |

your intended operations. |

| surface of the workpiece, puncturing |

|

| your hand or fingers. |

|

| |

|

|