Model W1822 (For Machines Mfg. Since 9/10)

SETUP

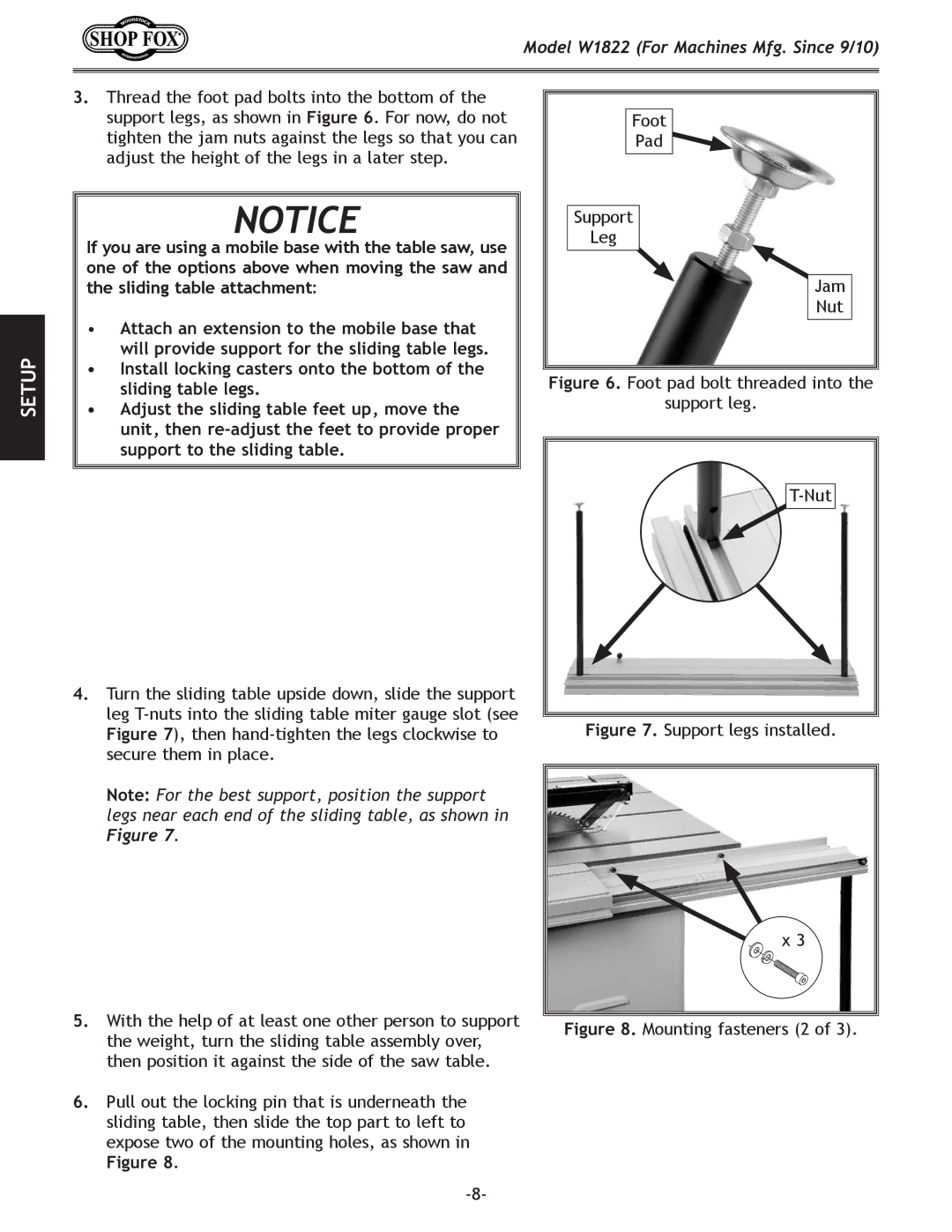

3.Thread the foot pad bolts into the bottom of the support legs, as shown in Figure 6. For now, do not tighten the jam nuts against the legs so that you can adjust the height of the legs in a later step.

NOTICE

If you are using a mobile base with the table saw, use one of the options above when moving the saw and the sliding table attachment:

•Attach an extension to the mobile base that will provide support for the sliding table legs.

•Install locking casters onto the bottom of the sliding table legs.

•Adjust the sliding table feet up, move the unit, then

4.Turn the sliding table upside down, slide the support leg

Note: For the best support, position the support legs near each end of the sliding table, as shown in Figure 7.

5.With the help of at least one other person to support the weight, turn the sliding table assembly over, then position it against the side of the saw table.

6.Pull out the locking pin that is underneath the sliding table, then slide the top part to left to expose two of the mounting holes, as shown in

Figure 8.

Foot

Pad ![]()

Support

Leg

Jam

Nut

Figure 6. Foot pad bolt threaded into the

support leg.

T-Nut

Figure 7. Support legs installed.

x 3