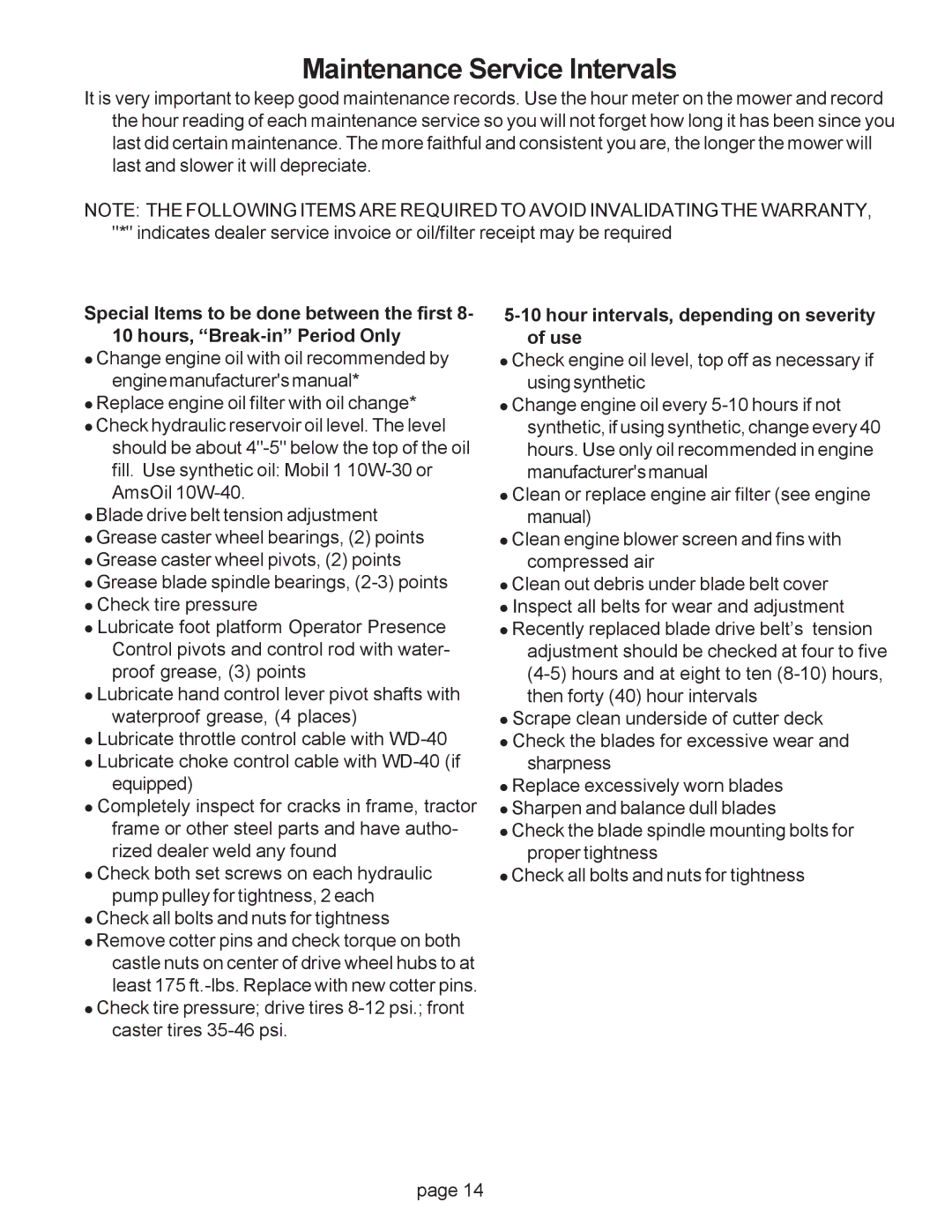

Maintenance Service Intervals

It is very important to keep good maintenance records. Use the hour meter on the mower and record the hour reading of each maintenance service so you will not forget how long it has been since you last did certain maintenance. The more faithful and consistent you are, the longer the mower will last and slower it will depreciate.

NOTE: THE FOLLOWING ITEMS ARE REQUIRED TO AVOID INVALIDATING THE WARRANTY, "*" indicates dealer service invoice or oil/filter receipt may be required

Special Items to be done between the first 8- 10 hours,

Change engine oil with oil recommended by engine manufacturer's manual*

Replace engine oil filter with oil change* Check hydraulic reservoir oil level. The level

should be about

Blade drive belt tension adjustment Grease caster wheel bearings, (2) points Grease caster wheel pivots, (2) points Grease blade spindle bearings,

Lubricate foot platform Operator Presence Control pivots and control rod with water- proof grease, (3) points

Lubricate hand control lever pivot shafts with waterproof grease, (4 places)

Lubricate throttle control cable with

equipped)

Completely inspect for cracks in frame, tractor frame or other steel parts and have autho- rized dealer weld any found

Check both set screws on each hydraulic pump pulley for tightness, 2 each

Check all bolts and nuts for tightness Remove cotter pins and check torque on both

castle nuts on center of drive wheel hubs to at least 175

Check tire pressure; drive tires

5-10 hour intervals, depending on severity of use

Check engine oil level, top off as necessary if using synthetic

Change engine oil every

Clean or replace engine air filter (see engine manual)

Clean engine blower screen and fins with compressed air

Clean out debris under blade belt cover Inspect all belts for wear and adjustment Recently replaced blade drive belt’s tension

adjustment should be checked at four to five

Scrape clean underside of cutter deck Check the blades for excessive wear and

sharpness

Replace excessively worn blades Sharpen and balance dull blades Check the blade spindle mounting bolts for

proper tightness

Check all bolts and nuts for tightness

page 14