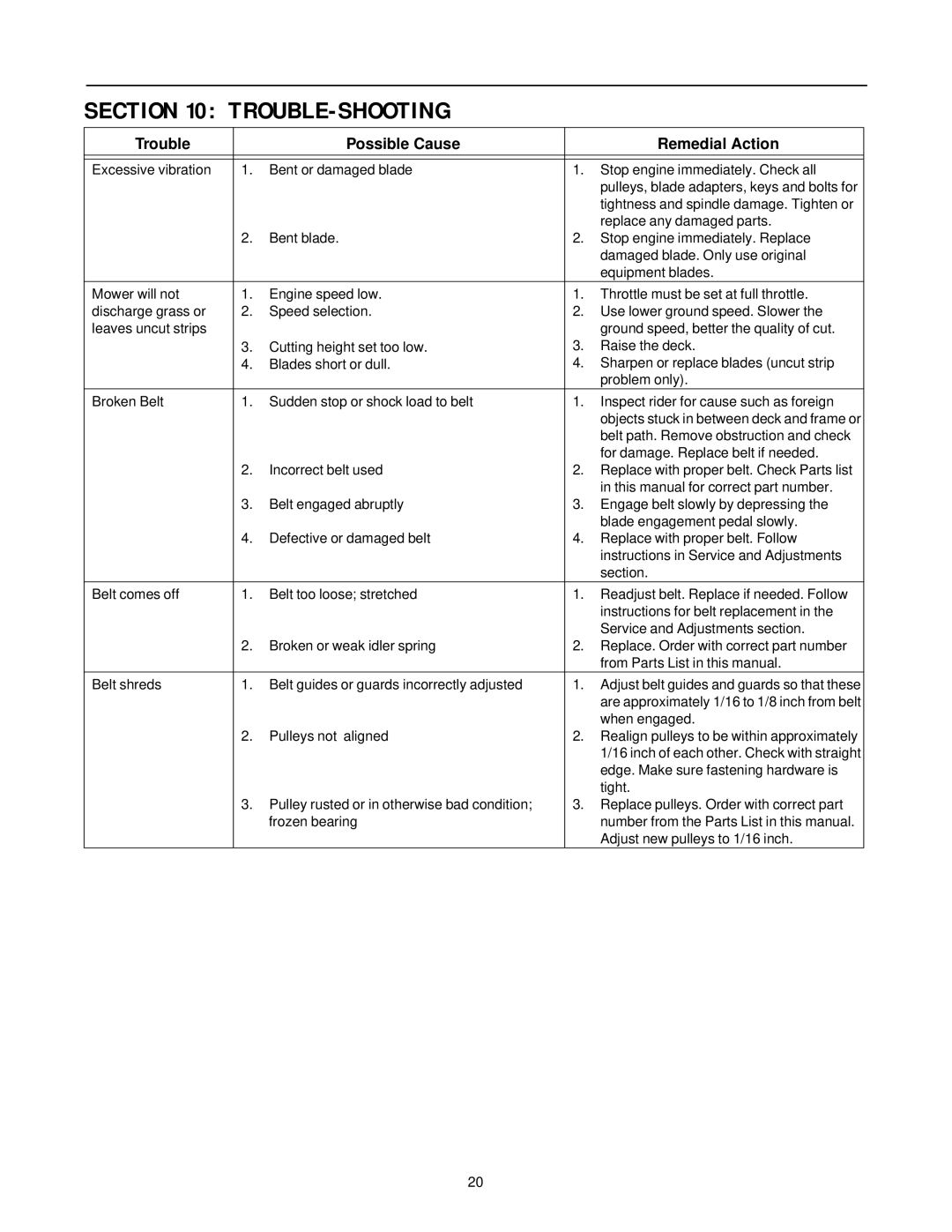

SECTION 10: TROUBLE-SHOOTING

Trouble |

| Possible Cause |

| Remedial Action |

|

|

|

|

|

|

|

|

|

|

Excessive vibration | 1. | Bent or damaged blade | 1. | Stop engine immediately. Check all |

|

|

|

| pulleys, blade adapters, keys and bolts for |

|

|

|

| tightness and spindle damage. Tighten or |

|

|

|

| replace any damaged parts. |

| 2. | Bent blade. | 2. | Stop engine immediately. Replace |

|

|

|

| damaged blade. Only use original |

|

|

|

| equipment blades. |

Mower will not | 1. | Engine speed low. | 1. | Throttle must be set at full throttle. |

discharge grass or | 2. | Speed selection. | 2. | Use lower ground speed. Slower the |

leaves uncut strips |

|

|

| ground speed, better the quality of cut. |

| 3. | Cutting height set too low. | 3. | Raise the deck. |

| 4. | Blades short or dull. | 4. | Sharpen or replace blades (uncut strip |

|

|

|

| problem only). |

Broken Belt | 1. | Sudden stop or shock load to belt | 1. | Inspect rider for cause such as foreign |

|

|

|

| objects stuck in between deck and frame or |

|

|

|

| belt path. Remove obstruction and check |

|

|

|

| for damage. Replace belt if needed. |

| 2. | Incorrect belt used | 2. | Replace with proper belt. Check Parts list |

|

|

|

| in this manual for correct part number. |

| 3. | Belt engaged abruptly | 3. | Engage belt slowly by depressing the |

|

|

|

| blade engagement pedal slowly. |

| 4. | Defective or damaged belt | 4. | Replace with proper belt. Follow |

|

|

|

| instructions in Service and Adjustments |

|

|

|

| section. |

Belt comes off | 1. | Belt too loose; stretched | 1. | Readjust belt. Replace if needed. Follow |

|

|

|

| instructions for belt replacement in the |

|

|

|

| Service and Adjustments section. |

| 2. | Broken or weak idler spring | 2. | Replace. Order with correct part number |

|

|

|

| from Parts List in this manual. |

Belt shreds | 1. | Belt guides or guards incorrectly adjusted | 1. | Adjust belt guides and guards so that these |

|

|

|

| are approximately 1/16 to 1/8 inch from belt |

|

|

|

| when engaged. |

| 2. | Pulleys not aligned | 2. | Realign pulleys to be within approximately |

|

|

|

| 1/16 inch of each other. Check with straight |

|

|

|

| edge. Make sure fastening hardware is |

|

|

|

| tight. |

| 3. | Pulley rusted or in otherwise bad condition; | 3. | Replace pulleys. Order with correct part |

|

| frozen bearing |

| number from the Parts List in this manual. |

|

|

|

| Adjust new pulleys to 1/16 inch. |

20