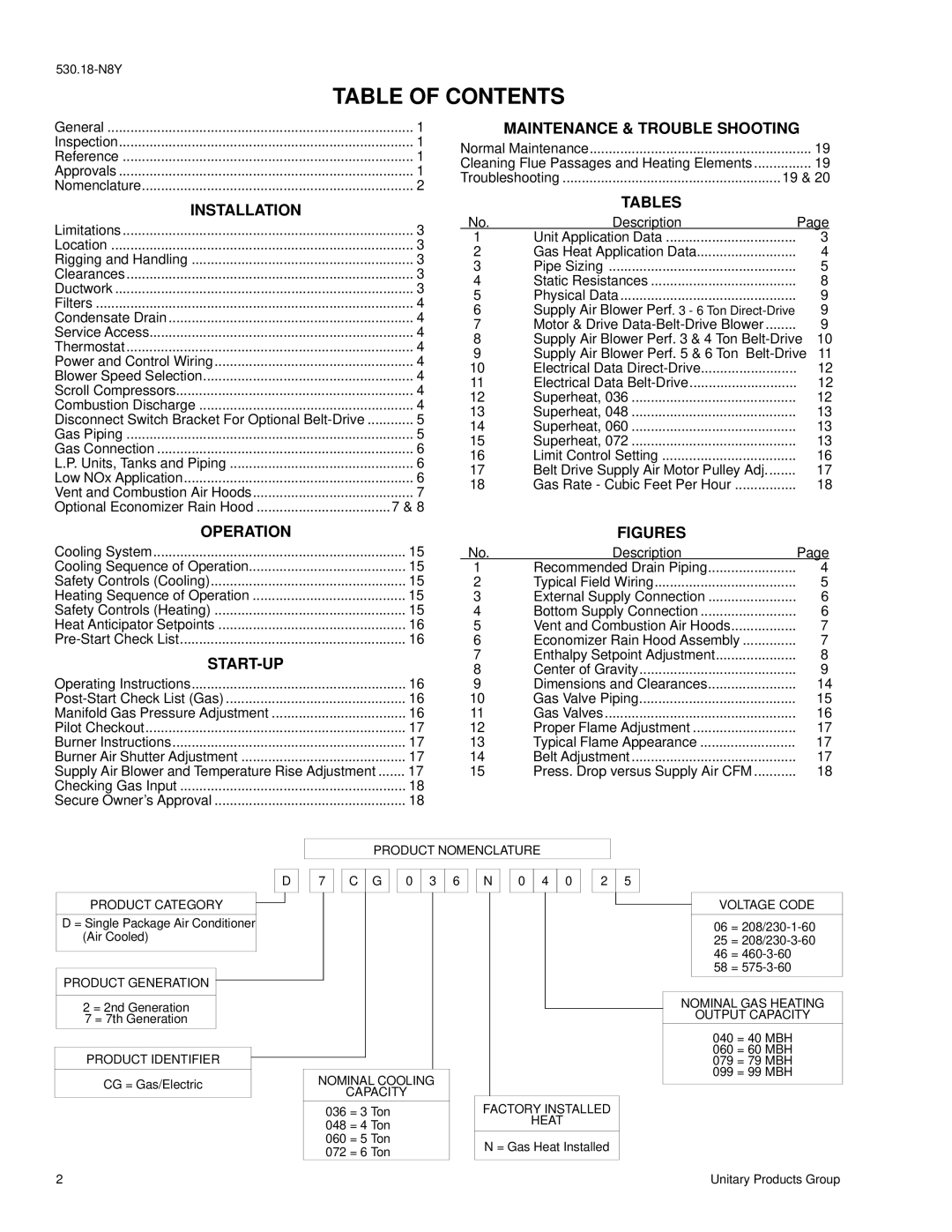

D2CG 072, D7CG 060, D7CG 048, D7CG 036 specifications

The York D7CG 060, D7CG 048, D7CG 036, and D2CG 072 are advanced rooftop unit models designed for enhanced energy efficiency, reliability, and ease of use in commercial HVAC applications. These models are known for their robust features and technologies aimed at providing optimal indoor climate control.The D7CG series, including the 060, 048, and 036 models, is built around a highly efficient design. They incorporate scroll compressors that operate quietly, contributing to a comfortable environment. The units are designed for high-ambient performance, enabling them to function efficiently even in extreme temperature conditions. The D7CG series also features an intelligent control system that allows for seamless integration with building management systems, optimizing energy usage and enhancing overall system performance.

One of the standout features of the D7CG models is their advanced heat exchanger technology, which improves heat transfer and overall efficiency. The coil design allows for superior airflow and enhanced temperature regulation, ensuring consistent comfort levels throughout the space. With variable-speed fans, these units adjust airflow dynamically, providing further energy savings and tailored climate control.

The D2CG 072 model, on the other hand, accentuates versatility and robustness. This unit also boasts a high-efficiency compressor and features a unique multi-stage heating and cooling process. Its modular design allows for easy installation and maintenance. The D2CG 072 is engineered for flexible configurations, accommodating various building sizes and layouts without compromising performance.

All four models are equipped with user-friendly digital controls that offer precise adjustments and monitoring capabilities. This feature allows building operators to quickly respond to changing conditions, ensuring optimal comfort for occupants while maintaining energy efficiency. Furthermore, they adhere to stringent environmental standards, incorporating low-GWP refrigerants that minimize their ecological footprint.

In summary, the York D7CG 060, D7CG 048, D7CG 036, and D2CG 072 models represent cutting-edge technology and innovative design in the commercial HVAC sector. Their high efficiency, advanced features, and user-centric controls make them suitable for a wide range of applications, ensuring reliable performance and comfort in diverse environments.