ZM400/ZM600

VIII. APPENDIX A (ZM400)

Technical Specifications Sheets

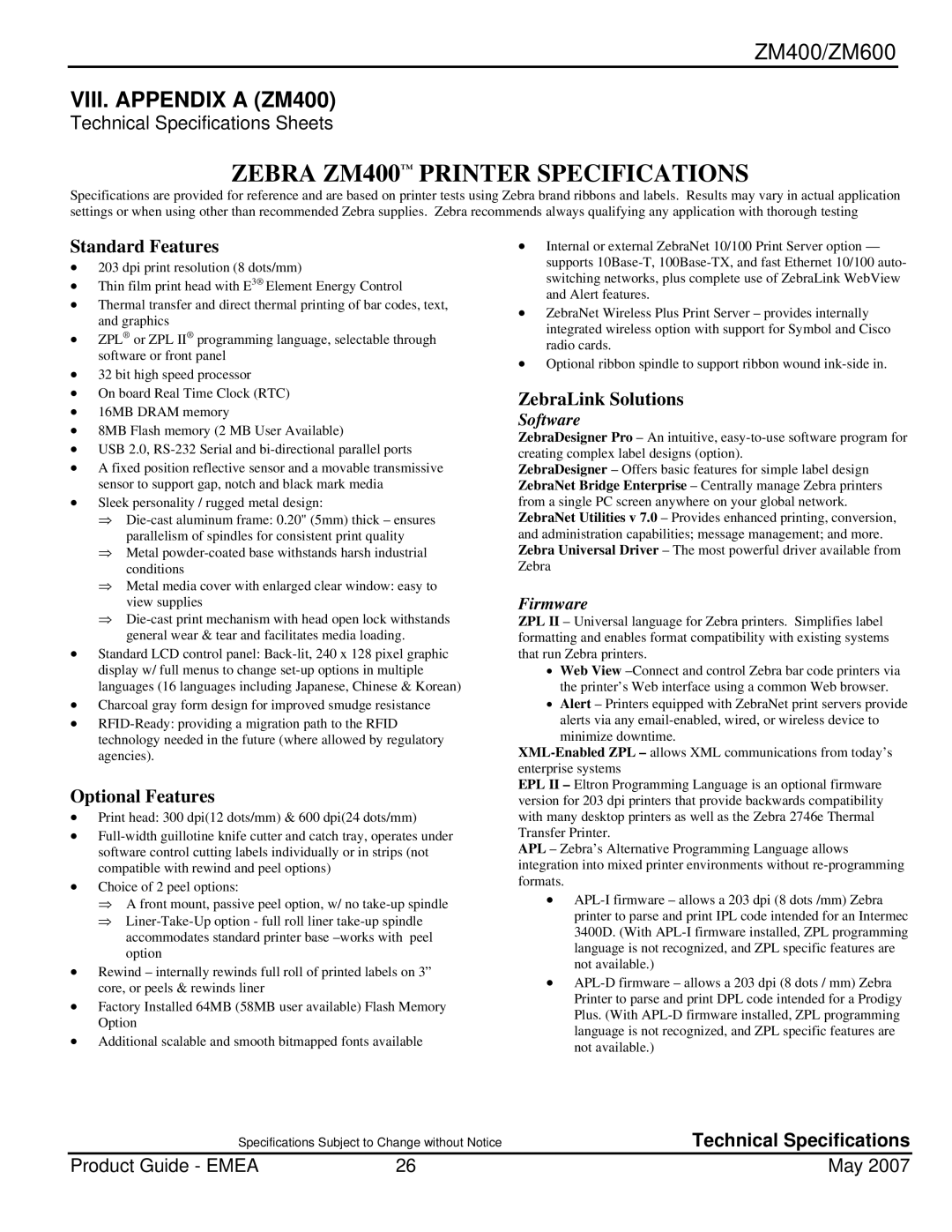

ZEBRA ZM400™ PRINTER SPECIFICATIONS

Specifications are provided for reference and are based on printer tests using Zebra brand ribbons and labels. Results may vary in actual application settings or when using other than recommended Zebra supplies. Zebra recommends always qualifying any application with thorough testing

Standard Features | • Internal or external ZebraNet 10/100 Print Server option — | |||

• 203 dpi print resolution (8 dots/mm) | supports | |||

• | Thin film print head with E3® Element Energy Control | switching networks, plus complete use of ZebraLink WebView | ||

• Thermal transfer and direct thermal printing of bar codes, text, | and Alert features. | |||

• ZebraNet Wireless Plus Print Server – provides internally | ||||

| and graphics | |||

| integrated wireless option with support for Symbol and Cisco | |||

• ZPL® or ZPL II® programming language, selectable through | ||||

radio cards. | ||||

| software or front panel | |||

| • Optional ribbon spindle to support ribbon wound | |||

• 32 bit high speed processor | ||||

|

| |||

• On board Real Time Clock (RTC) | ZebraLink Solutions | |||

• | 16MB DRAM memory | Software | ||

• 8MB Flash memory (2 MB User Available) | ||||

ZebraDesigner Pro – An intuitive, | ||||

• USB 2.0, | ||||

creating complex label designs (option). | ||||

• A fixed position reflective sensor and a movable transmissive | ZebraDesigner – Offers basic features for simple label design | |||

| sensor to support gap, notch and black mark media | ZebraNet Bridge Enterprise – Centrally manage Zebra printers | ||

• Sleek personality / rugged metal design: | from a single PC screen anywhere on your global network. | |||

| ⇒ | ZebraNet Utilities v 7.0 – Provides enhanced printing, conversion, | ||

| parallelism of spindles for consistent print quality | and administration capabilities; message management; and more. | ||

| ⇒ Metal | Zebra Universal Driver – The most powerful driver available from | ||

| conditions | Zebra |

| |

| ⇒ Metal media cover with enlarged clear window: easy to | Firmware | ||

| view supplies | |||

| ⇒ | ZPL II – Universal language for Zebra printers. Simplifies label | ||

| general wear & tear and facilitates media loading. | formatting and enables format compatibility with existing systems | ||

• Standard LCD control panel: | that run Zebra printers. | |||

| display w/ full menus to change | • | Web View | |

| languages (16 languages including Japanese, Chinese & Korean) |

| the printer’s Web interface using a common Web browser. | |

• Charcoal gray form design for improved smudge resistance | • | Alert – Printers equipped with ZebraNet print servers provide | ||

• |

| alerts via any | ||

| technology needed in the future (where allowed by regulatory |

| minimize downtime. | |

| agencies). | |||

|

| enterprise systems | ||

Optional Features | EPL II – Eltron Programming Language is an optional firmware | |||

version for 203 dpi printers that provide backwards compatibility | ||||

• Print head: 300 dpi(12 dots/mm) & 600 dpi(24 dots/mm) | with many desktop printers as well as the Zebra 2746e Thermal | |||

• | Transfer Printer. | |||

| software control cutting labels individually or in strips (not | APL – Zebra’s Alternative Programming Language allows | ||

| compatible with rewind and peel options) | integration into mixed printer environments without | ||

• Choice of 2 peel options: | formats. | |||

| ⇒ A front mount, passive peel option, w/ no | • | ||

| ⇒ |

| printer to parse and print IPL code intended for an Intermec | |

| accommodates standard printer base | 3400D. (With | |

| language is not recognized, and ZPL specific features are | ||

| option | ||

• | not available.) | ||

Rewind – internally rewinds full roll of printed labels on 3” | |||

• | |||

| core, or peels & rewinds liner | ||

• | Printer to parse and print DPL code intended for a Prodigy | ||

Factory Installed 64MB (58MB user available) Flash Memory | |||

Plus. (With | |||

| Option | ||

• | language is not recognized, and ZPL specific features are | ||

Additional scalable and smooth bitmapped fonts available | |||

not available.) | |||

|

|

Specifications Subject to Change without Notice | Technical Specifications | |

Product Guide - EMEA | 26 | May 2007 |