MA1

MA2

English

8. Maintenance

![]() WARNING

WARNING

Before cleaning, inspecting or repairing your unit, make sure that engine has stopped and is cool. Disconnect the spark plug terminal to avoid accidental engine starts.

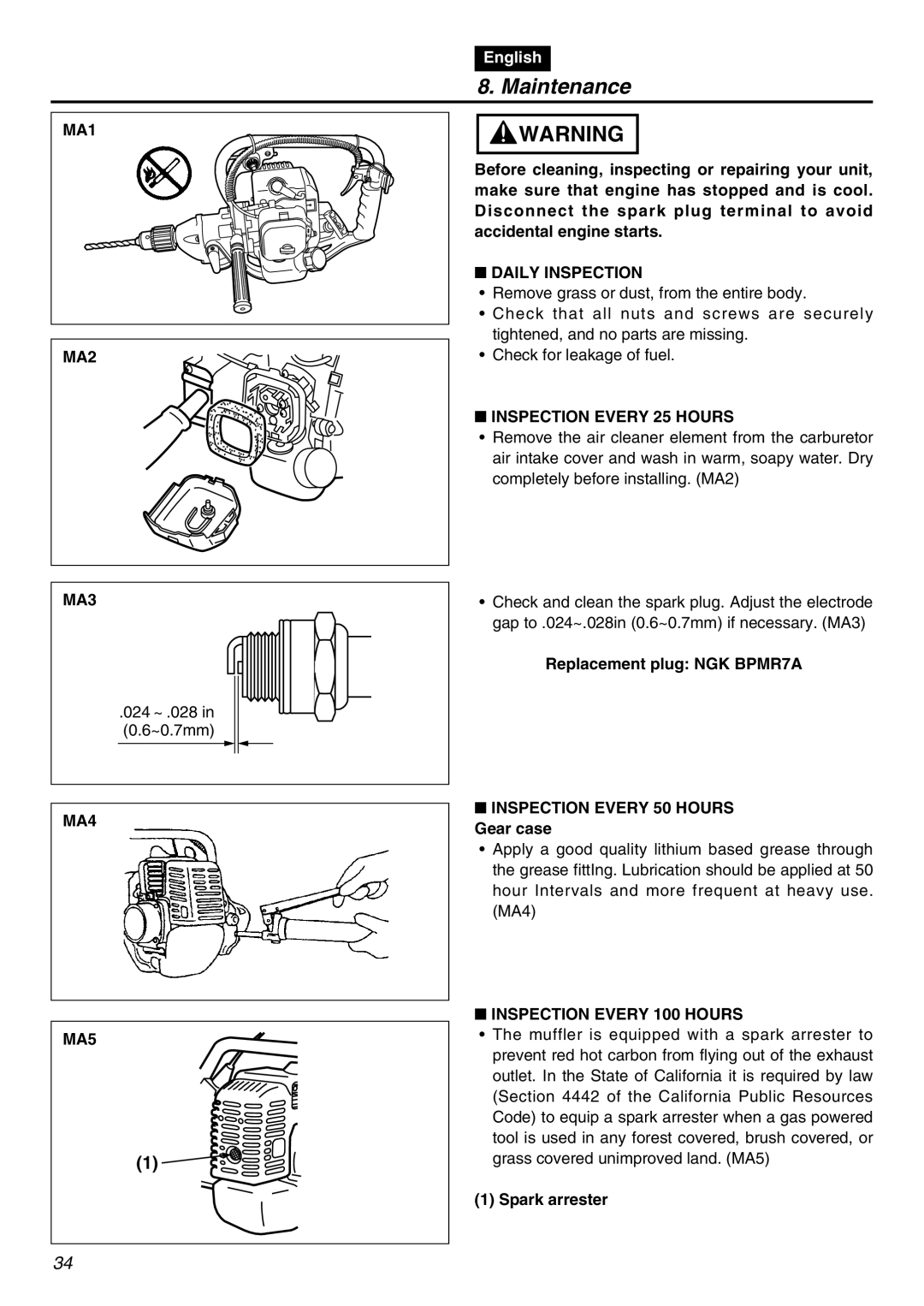

■DAILY INSPECTION

•Remove grass or dust, from the entire body.

•Check that all nuts and screws are securely tightened, and no parts are missing.

•Check for leakage of fuel.

■INSPECTION EVERY 25 HOURS

•Remove the air cleaner element from the carburetor air intake cover and wash in warm, soapy water. Dry completely before installing. (MA2)

MA3

.024 ~ .028 in (0.6~0.7mm)

MA4

MA5

(1) ![]()

•Check and clean the spark plug. Adjust the electrode gap to .024~.028in (0.6~0.7mm) if necessary. (MA3)

Replacement plug: NGK BPMR7A

■INSPECTION EVERY 50 HOURS Gear case

• Apply a good quality lithium based grease through the grease fittIng. Lubrication should be applied at 50 hour Intervals and more frequent at heavy use. (MA4)

■INSPECTION EVERY 100 HOURS

•The muffler is equipped with a spark arrester to prevent red hot carbon from flying out of the exhaust outlet. In the State of California it is required by law (Section 4442 of the California Public Resources Code) to equip a spark arrester when a gas powered tool is used in any forest covered, brush covered, or grass covered unimproved land. (MA5)

(1) Spark arrester

34