9. Maintenance

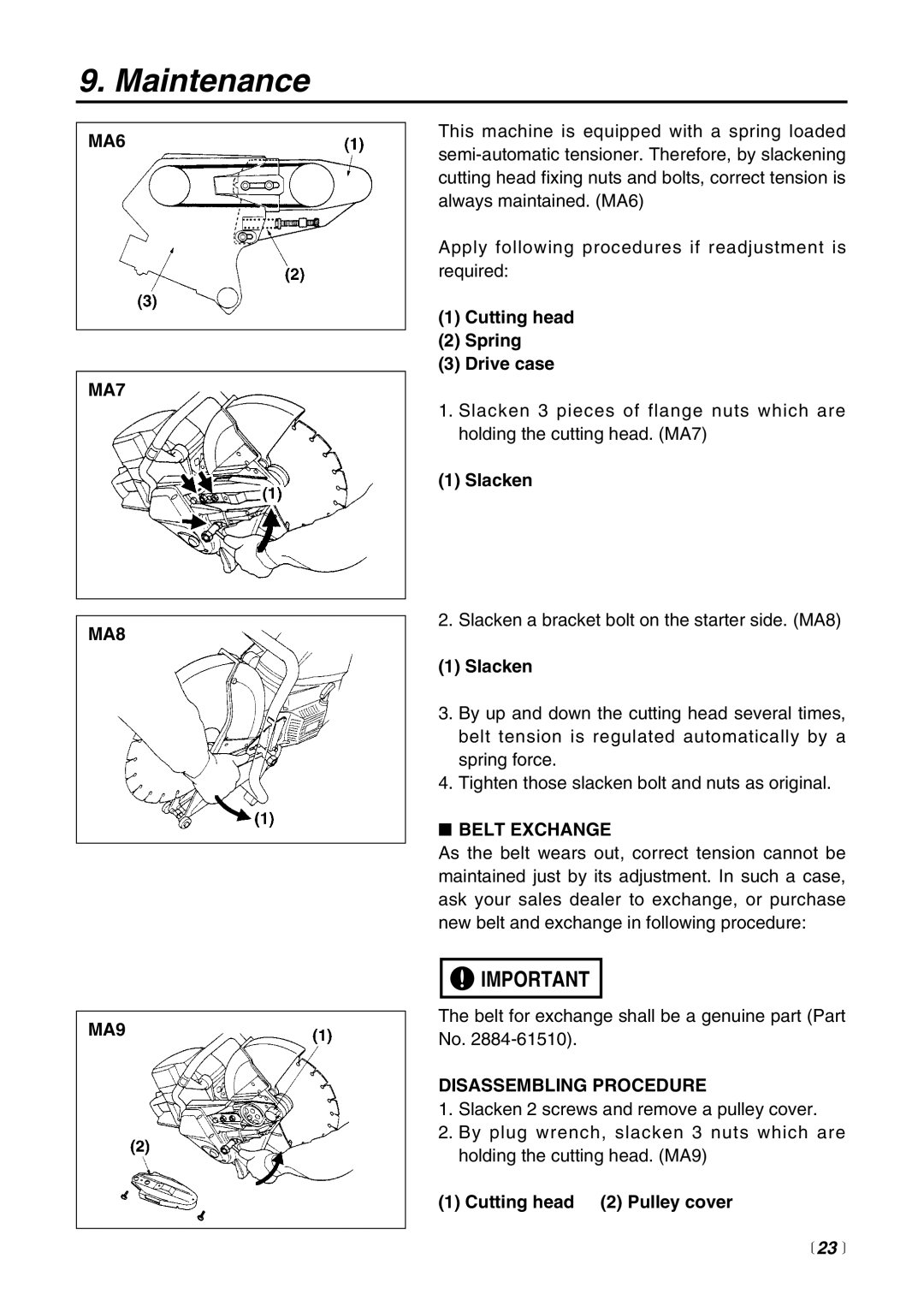

MA6

MA7

MA8

MA9

This machine is equipped with a spring loaded

Apply following procedures if readjustment is required:

(1)Cutting head

(2)Spring

(3)Drive case

1.Slacken 3 pieces of flange nuts which are holding the cutting head. (MA7)

(1) Slacken

2. Slacken a bracket bolt on the starter side. (MA8)

(1) Slacken

3.By up and down the cutting head several times, belt tension is regulated automatically by a spring force.

4.Tighten those slacken bolt and nuts as original.

■BELT EXCHANGE

As the belt wears out, correct tension cannot be maintained just by its adjustment. In such a case, ask your sales dealer to exchange, or purchase new belt and exchange in following procedure:

![]()

![]() IMPORTANT

IMPORTANT

The belt for exchange shall be a genuine part (Part No.

DISASSEMBLING PROCEDURE

1.Slacken 2 screws and remove a pulley cover.

2.By plug wrench, slacken 3 nuts which are holding the cutting head. (MA9)

(1) Cutting head (2) Pulley cover

23