8. Maintenance

could cause the engine to catch on fire. Always make sure that the muffler is clean and free of wood chips, leaves, and other waste before use.

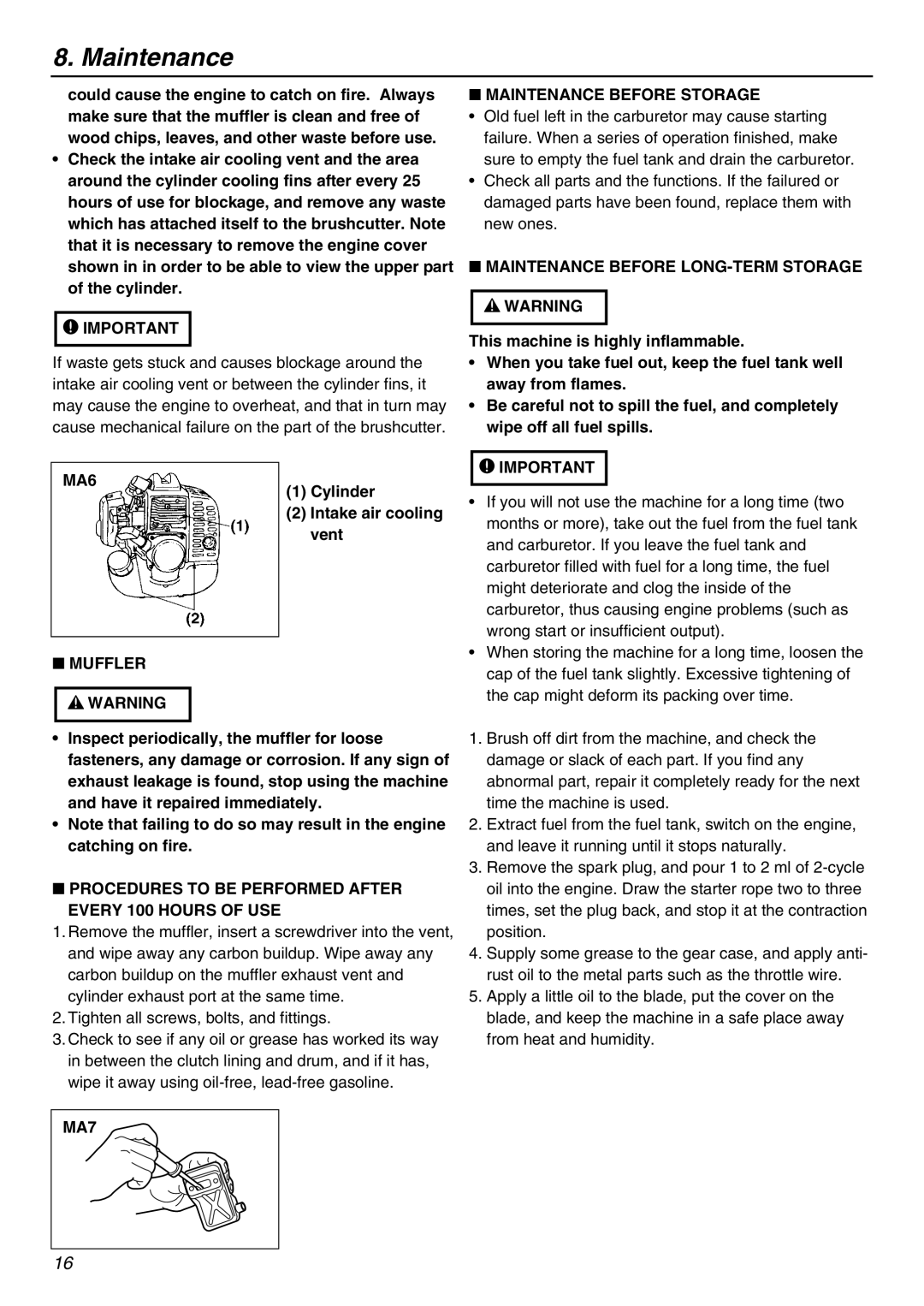

•Check the intake air cooling vent and the area around the cylinder cooling fins after every 25 hours of use for blockage, and remove any waste which has attached itself to the brushcutter. Note that it is necessary to remove the engine cover shown in in order to be able to view the upper part of the cylinder.

![]()

![]() IMPORTANT

IMPORTANT

If waste gets stuck and causes blockage around the intake air cooling vent or between the cylinder fins, it may cause the engine to overheat, and that in turn may cause mechanical failure on the part of the brushcutter.

MA6

(1) Cylinder

(2) Intake air cooling vent

■MUFFLER

![]() WARNING

WARNING

■MAINTENANCE BEFORE STORAGE

•Old fuel left in the carburetor may cause starting failure. When a series of operation finished, make sure to empty the fuel tank and drain the carburetor.

•Check all parts and the functions. If the failured or damaged parts have been found, replace them with new ones.

■MAINTENANCE BEFORE LONG-TERM STORAGE

![]() WARNING

WARNING

This machine is highly inflammable.

•When you take fuel out, keep the fuel tank well away from flames.

•Be careful not to spill the fuel, and completely wipe off all fuel spills.

![]()

![]() IMPORTANT

IMPORTANT

•If you will not use the machine for a long time (two months or more), take out the fuel from the fuel tank and carburetor. If you leave the fuel tank and carburetor filled with fuel for a long time, the fuel might deteriorate and clog the inside of the carburetor, thus causing engine problems (such as wrong start or insufficient output).

•When storing the machine for a long time, loosen the cap of the fuel tank slightly. Excessive tightening of the cap might deform its packing over time.

•Inspect periodically, the muffler for loose fasteners, any damage or corrosion. If any sign of exhaust leakage is found, stop using the machine and have it repaired immediately.

•Note that failing to do so may result in the engine catching on fire.

■PROCEDURES TO BE PERFORMED AFTER

EVERY 100 HOURS OF USE

1.Remove the muffler, insert a screwdriver into the vent, and wipe away any carbon buildup. Wipe away any carbon buildup on the muffler exhaust vent and cylinder exhaust port at the same time.

2.Tighten all screws, bolts, and fittings.

3.Check to see if any oil or grease has worked its way in between the clutch lining and drum, and if it has, wipe it away using

MA7

1.Brush off dirt from the machine, and check the damage or slack of each part. If you find any abnormal part, repair it completely ready for the next time the machine is used.

2.Extract fuel from the fuel tank, switch on the engine, and leave it running until it stops naturally.

3.Remove the spark plug, and pour 1 to 2 ml of

4.Supply some grease to the gear case, and apply anti- rust oil to the metal parts such as the throttle wire.

5.Apply a little oil to the blade, put the cover on the blade, and keep the machine in a safe place away from heat and humidity.

16