Workshop Manual

Brushcutter, Trimmer

Model 343R, 345RX, 343F, 345FX, 345FXT

Contents

General recommendations ___________________ 2

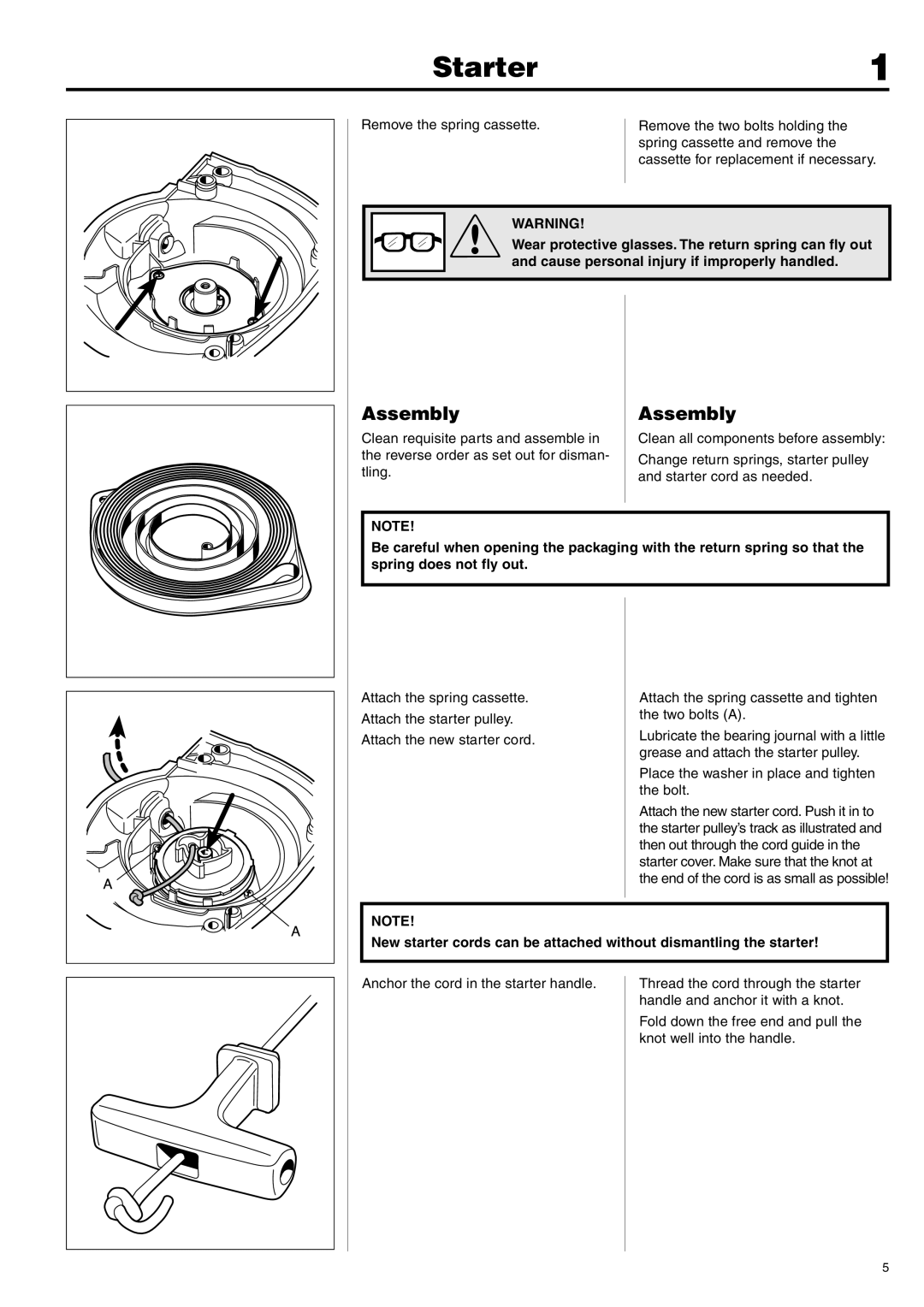

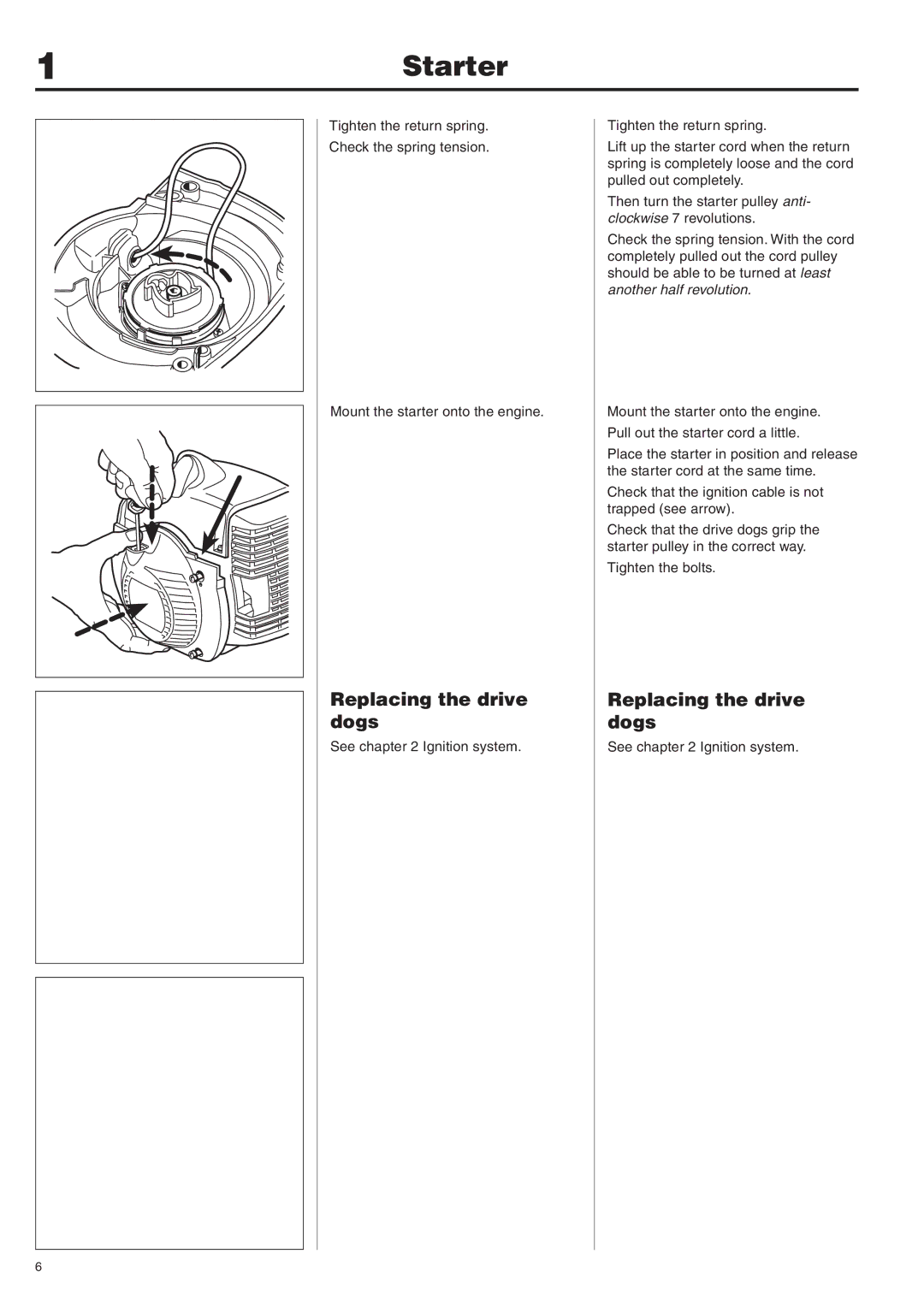

1.Starter __________________________________ 3

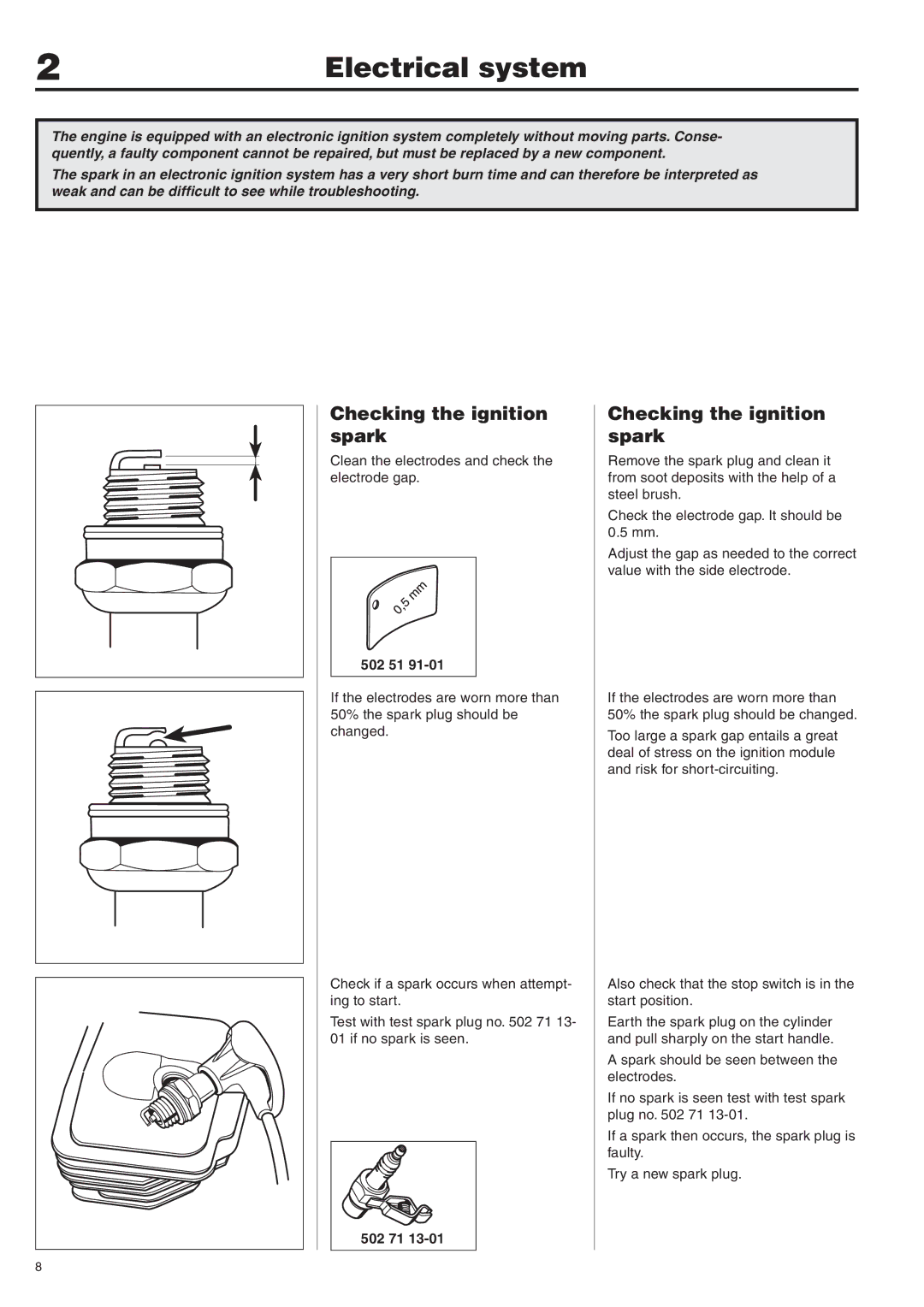

2.Electrical system _________________________ 7

3.Fuel system _____________________________ 15

4.Centrifugal clutch ________________________ 31

5.Angle gear ______________________________ 37

6.Cylinder and piston ______________________ 41

7.Crankshaft and crankcase _________________ 51

© Copyright Husqvarna AB, Sweden 2003

1