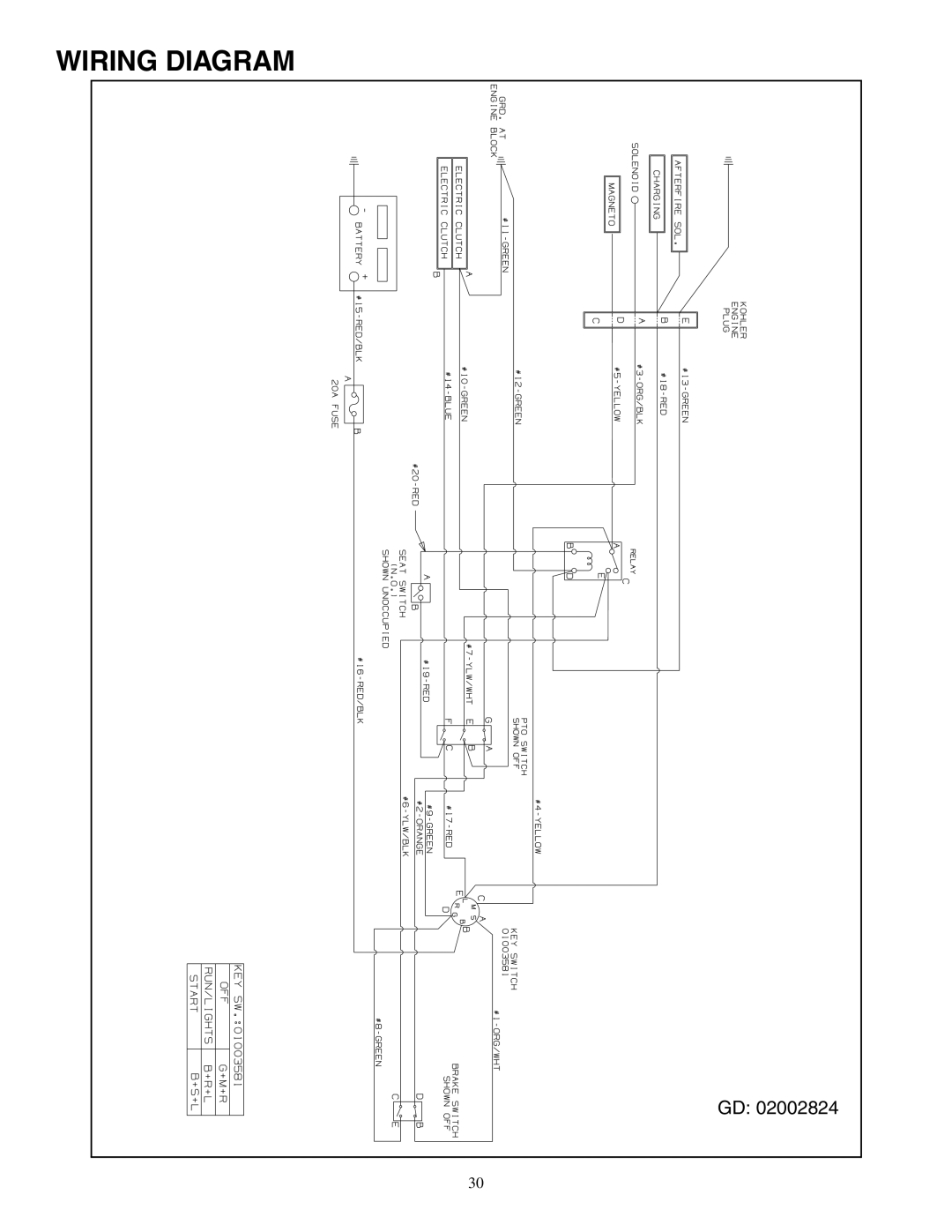

when slight contact with the feeler gage occurs. Engage the BBC (PTO Clutch) a couple of times, and

b.Steering lever/Parking Brake Switch: Sit in the operator’s seat. With both steering levers in the neutral position and the blade clutch switch “off”, release the parking brake and try to start the engine. The engine should not start. If it does, the park- ing brake switch must be repositioned or perhaps replaced. If the engine does not start, engage the parking brake and start the engine.

c.Seat Switch: With both steering levers in the neutral position, the parking brake engaged and the blade clutch switch in the “off” position, start the engine. Now release the parking brake, hold down on the back of the operator’s seat against spring pressure. Release the operator’s seat and the engine should stop. If the engine does not stop, the seat switch must be replaced. With both steering levers in the neutral position, the parking brake engaged and the blade clutch switch in the “off” position, sit in the operator’s seat and start the engine. Turn the blade clutch switch to the “on” position and the blades should start to rotate. Raise up slightly off the operator’s seat and the blades should stop. If the blades do not stop when you dismount from the operator’s seat, the seat switch must be replaced.

d.Electric PTO Clutch: This clutch operates when the engine is running, the operator is in the operator’s seat and the blade clutch switch is turned on.This electric clutch is a fairly trouble free device. If a problem develops and the blades do not turn, first check the 20 amp fuse in the yellow, 16- gauge wire between terminal “L” (for the Gasoline Engine) on the ignition switch and the hour meter and then investigate the wiring harness and the connections to the seat switch, the blade clutch switch and the electric blade clutch. Then check out the seat switch, the blade clutch switch and finally the electric blade clutch.

D.Tires

The two front wheels are caster wheels that are free to swivel to accommodate the direction of the Mower.

The two rear wheels are used to propel the Mower in the direction of input from the drive handles. Inflation pressure of the rear tires is important for stability

while the Mower is in operation. If the tire diameter is not equal between the two tires, the Mower will pull to one side.

1.Inflation Pressure:

a.Traction

b.Front Caster

c.Cutting Deck Ball

Use the Following guidelines for maintaining the tires:

a.Balance inflation pressure between the rear tires to help maintain straight travel (see tire side wall for proper inflation pres- sure).

b.Keep the valve caps tightened to prevent air pressure loss.

2.Leaking Tires: When a flat tire occurs, repair or replace immediately. The normal procedure is to remove the wheel and replace it with a spare. Take the leaking tire to a maintenance area and repair. If a tire is getting soft, park the mower on the nearest level, paved area. If the leaking tire is on a traction wheel, put blocks on each side of the opposite traction wheel and jack up the tire that leaks about an inch off the ground. Loosen and remove the lug nuts and remove the wheel. Mount a spare wheel and tire, replace the lug nuts, and using a torque wrench, tighten them to 60 ± 10

If the leaking tire is on a front caster wheel, block both traction wheels and raise the caster wheel so that the tire is an inch off the ground. Loosen and remove the locknut from the axle assembly and pull the axle assembly from the caster yoke. The wheel and two spacer sleeves will drop free. Slip the axle assembly through one side of the caster yoke, through a spacer sleeve, a spare wheel, the other spacer sleeve and finally through the other side of the caster yoke. Then tighten the locknut on the end of the axle assembly.

Lower the mower off the jack and continue mowing. The wheel with the leaking tire should be taken to the maintenance area, the tire inflated to 20 psi and the wheel placed in a large bucket of water. Carefully inspect the tire, rim and valve for escaping air bubbles which indicate a leak. Mark each leak with a yellow marking crayon and then deflate the tire to 8 psi and repeat the inspection. If the leaks you find are pin hole size to 1/16" diameter, the tire can be repaired using an aerosol can of tire inflater and latex sealer

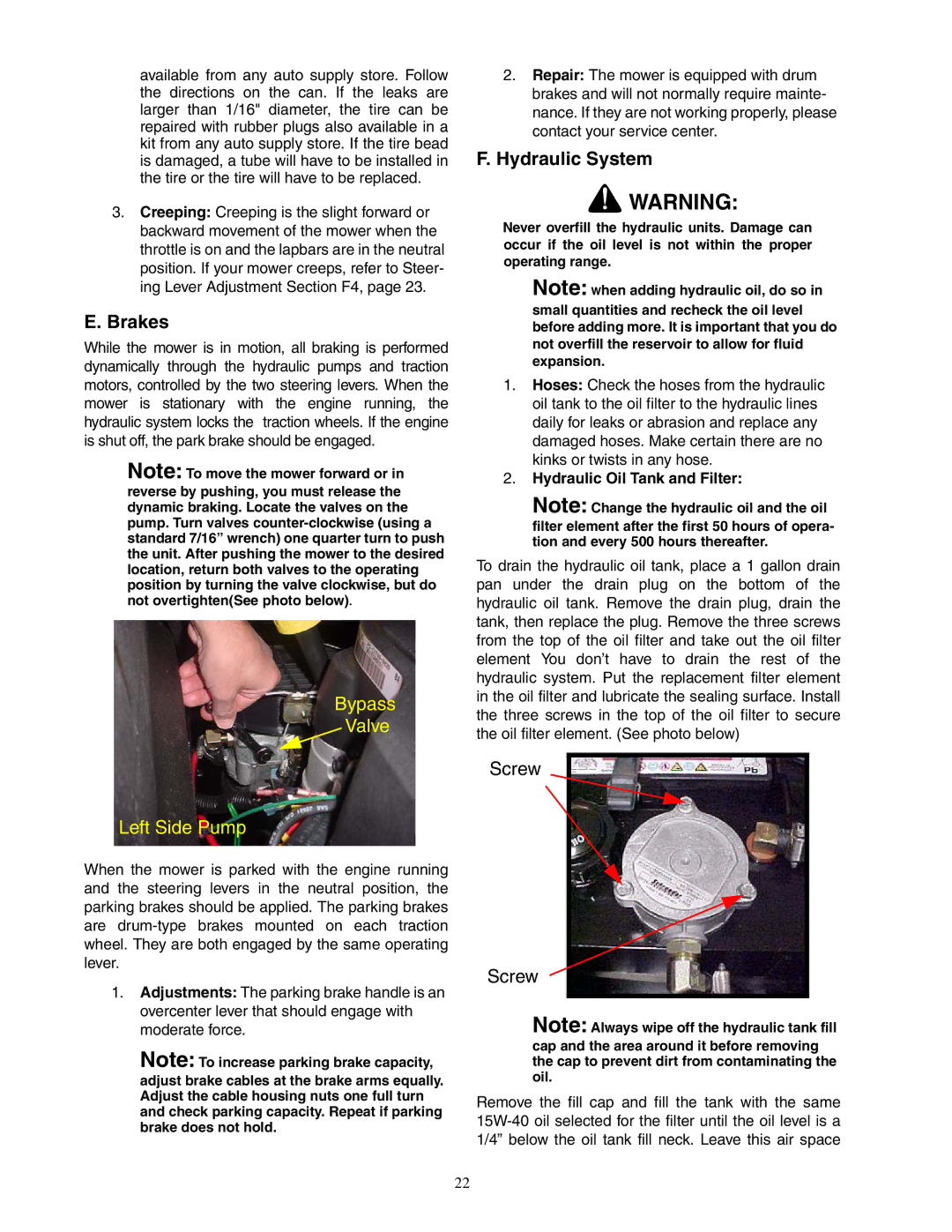

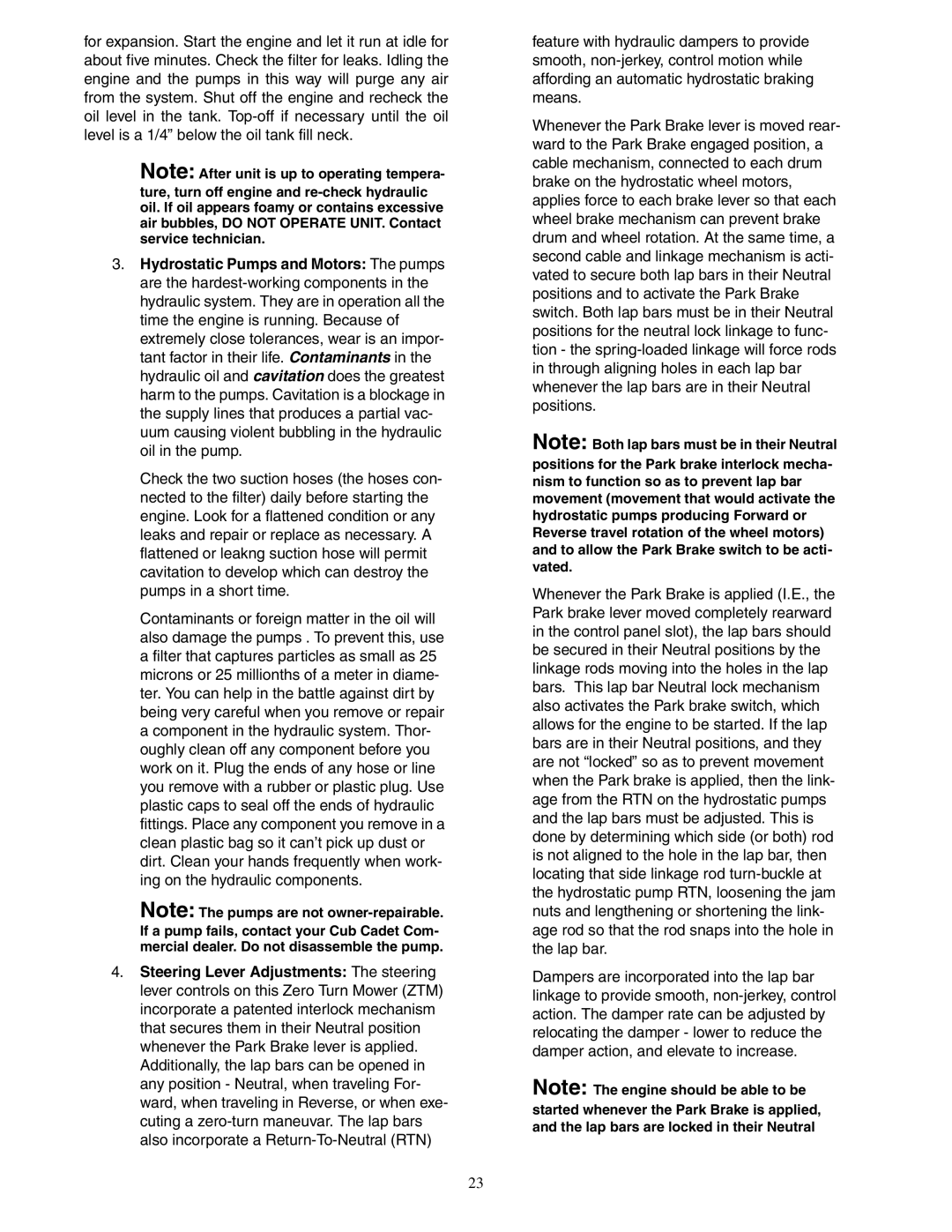

21