1. Introduction

The Mobrey Electropulse system is used for the detection of liquids or liquids with suspended / settled solids. It consists of three units, a sensor, a head amplifier unit, and a control room unit.

1.1 Sensors

There are many different Mobrey sensors available, but they fall into two categories:

a) Gap sensors

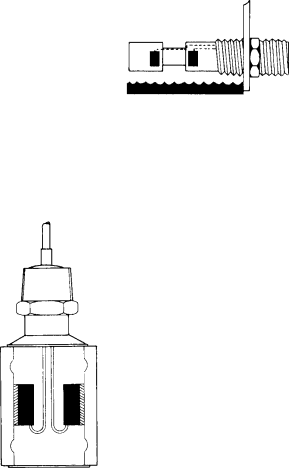

Figure 1.1 - Gap sensor, cut away to show construction

Gap sensors feature two ultrasonic transducers mounted one either side of the gap. When immersed in a liquid the signal transmitted is carried by the liquid across the gap, to the receiver, when the liquid level drops below the sensor, the signal cannot be carried across the gap, and is not received by the second transducer.

b) Hi-Sens cylindrical sensors

Figure 1.2 - Hi-Sens, cut- away to show construction

The

Use of

3