TROUBLESHOOTING | ||

|

|

|

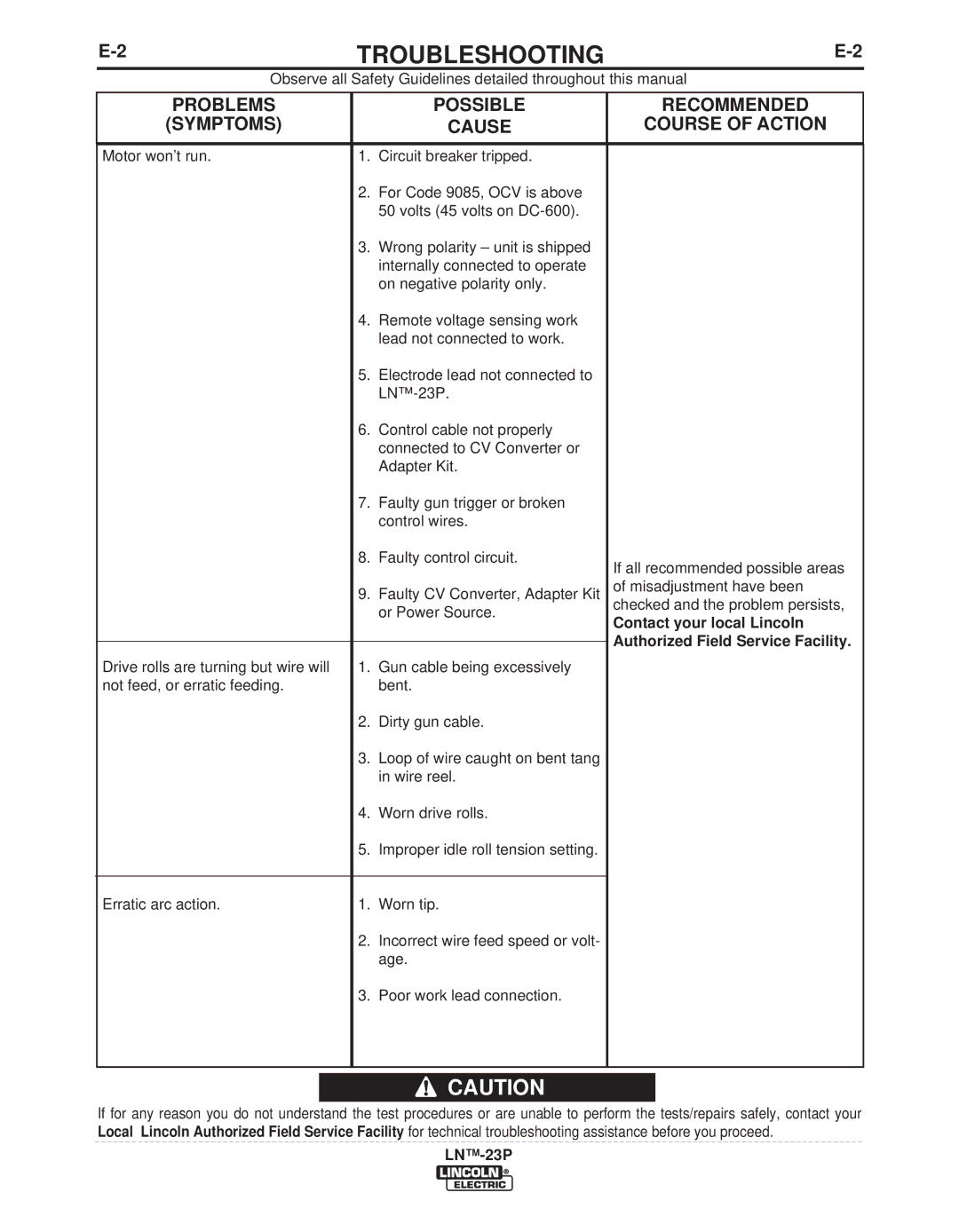

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Improper wire speed control. | 1. | Faulty printed circuit board, |

|

| faulty rheostat, or faulty motor. |

|

| |

Can’t obtain required voltage. | 1. Defective power source of CV | |

|

| Converter. |

| 2. | On SAM welders, constant |

|

| voltage control must be adjusted |

|

| to give required voltage and |

|

| mode switch must be set to |

|

| constant voltage position. |

| 3. | On transformer or inverter |

|

| welders, fine voltage control |

|

| switch must be set to remote |

|

| position. |

| 4. | Broken lead(s) in |

|

| |

| 5. | Defective voltage control |

|

| rheostat. |

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.