Flushing

![]() WARNING

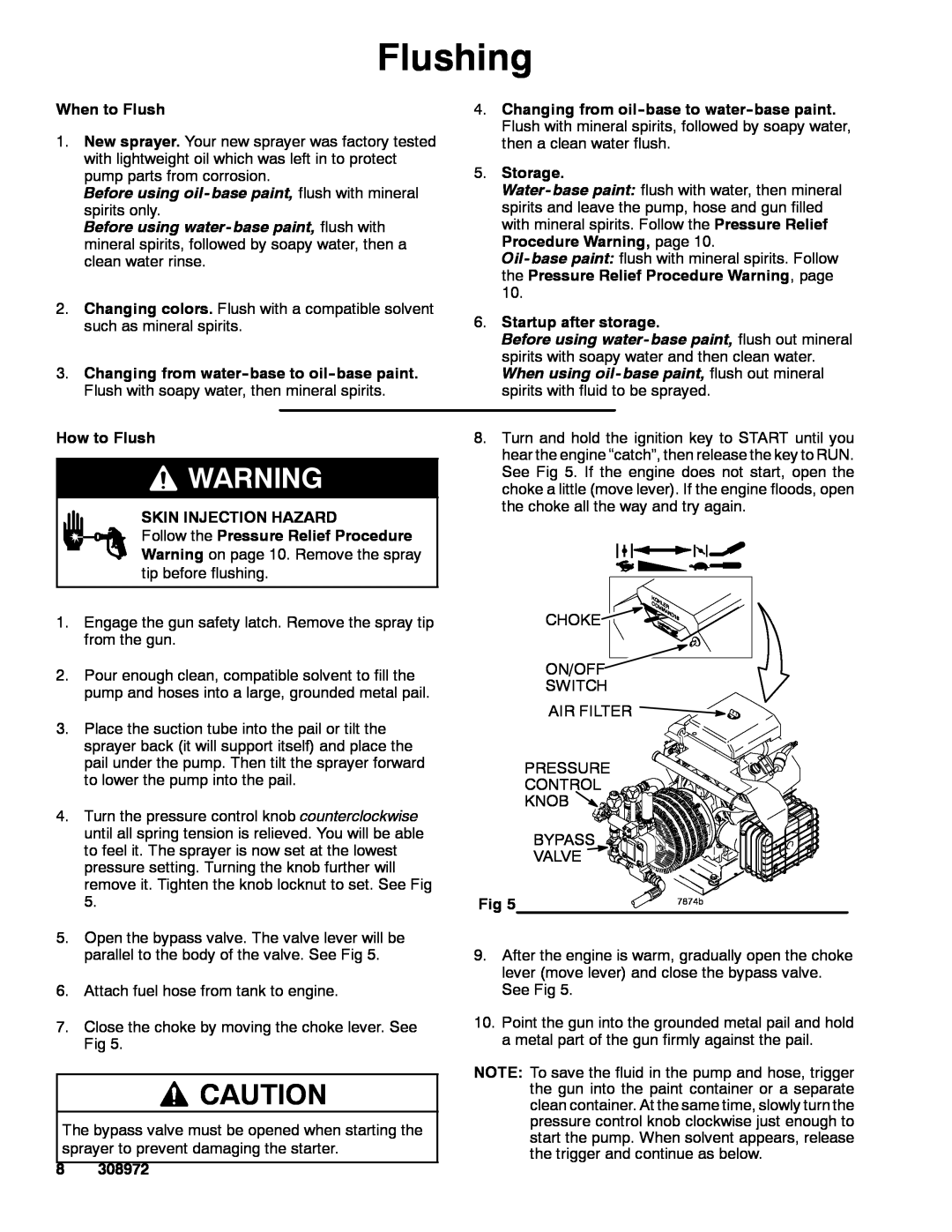

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking and

splashing when flushing, always remove the spray tip from the gun and hold a

metal part of the gun firmly to the side of a grounded metal pail.

11.Making firm

12.Circulate the solvent until the system is thoroughly flushed.

13.Release the trigger and engage the gun safety latch.

14.If you are going to start spraying, place the pump or suction tube into the supply container. Follow the Pressure Relief Procedure on page 10. Engage the gun safety latch until you are ready to prime the pump. See Step 3, page 9.

15.If you are going to store the sprayer, be sure your final flush is with an

308972 9