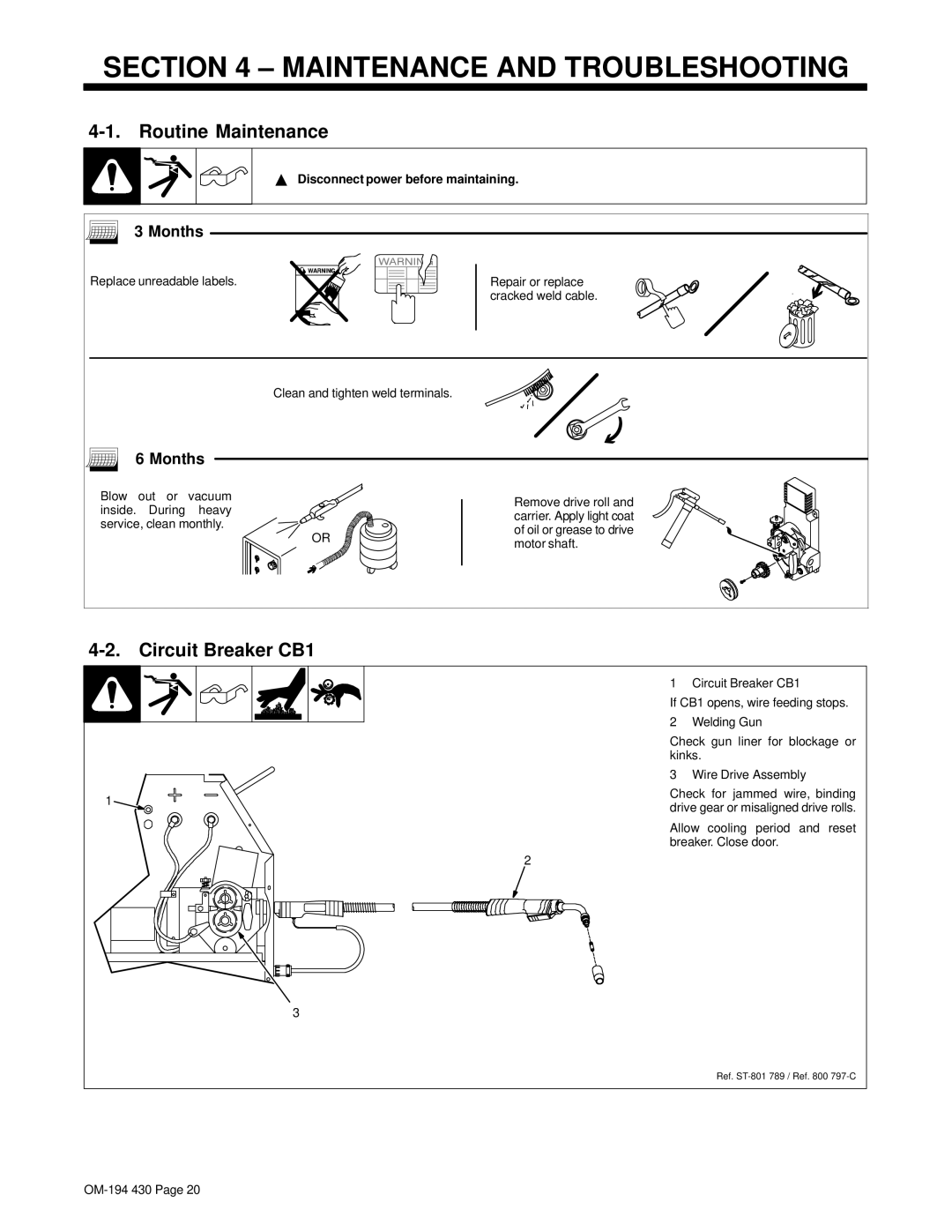

4-3. Unit Overload

If unit is used beyond capacity (excessive wire feed, shorted output, etc.), wire feeds but is not energized. Release gun trigger to reset this condition.

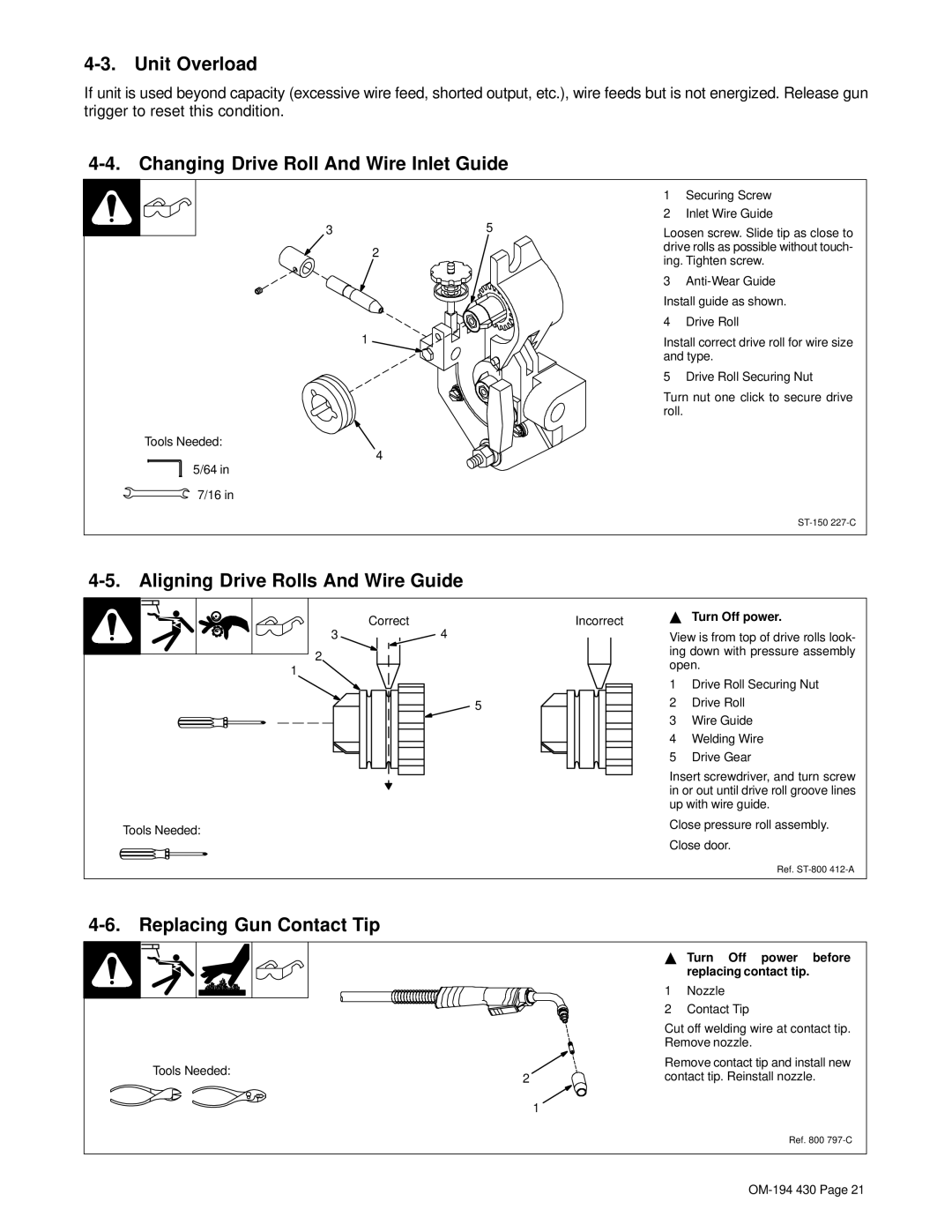

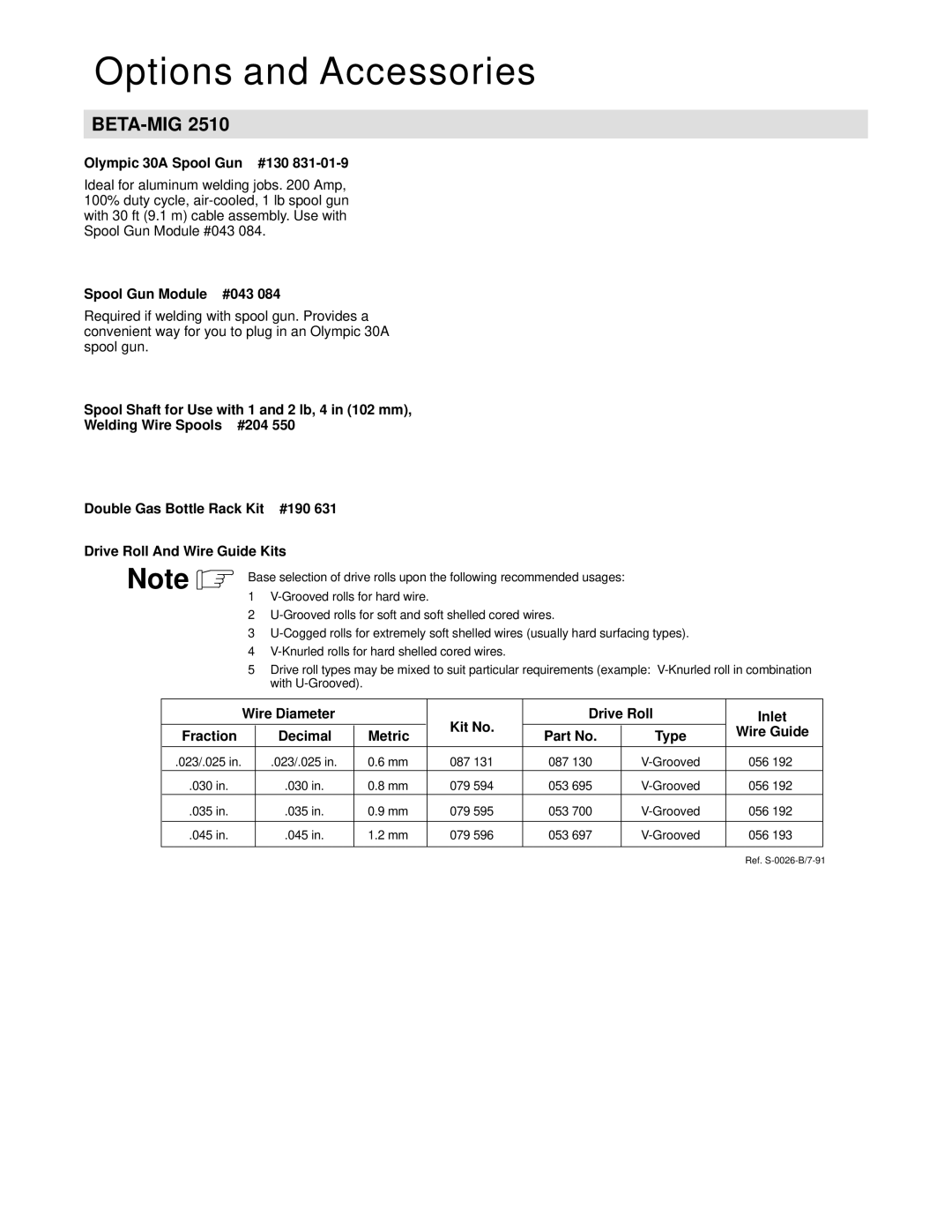

4-4. Changing Drive Roll And Wire Inlet Guide

3 | 5 |

2

1

Tools Needed:

4

5/64 in

7/16 in

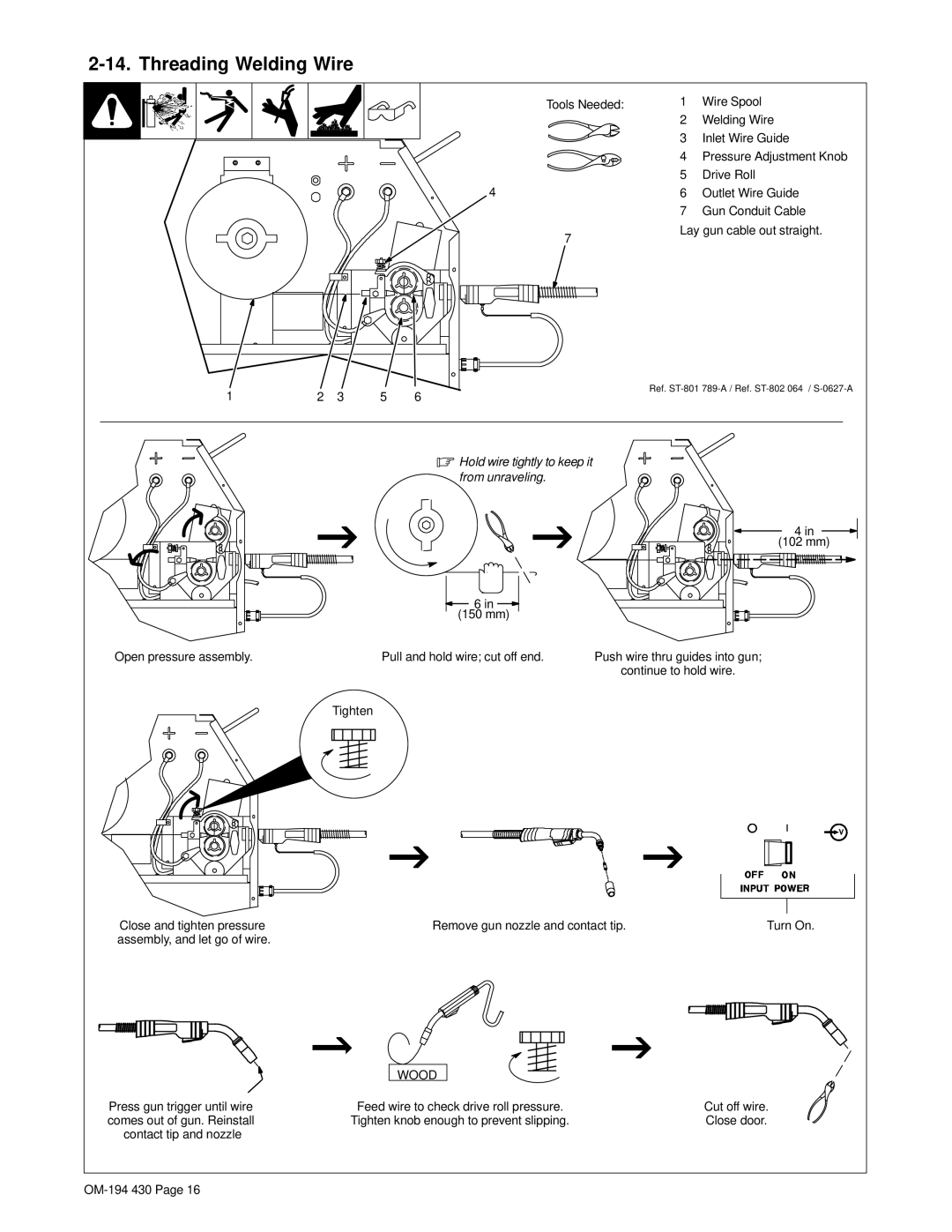

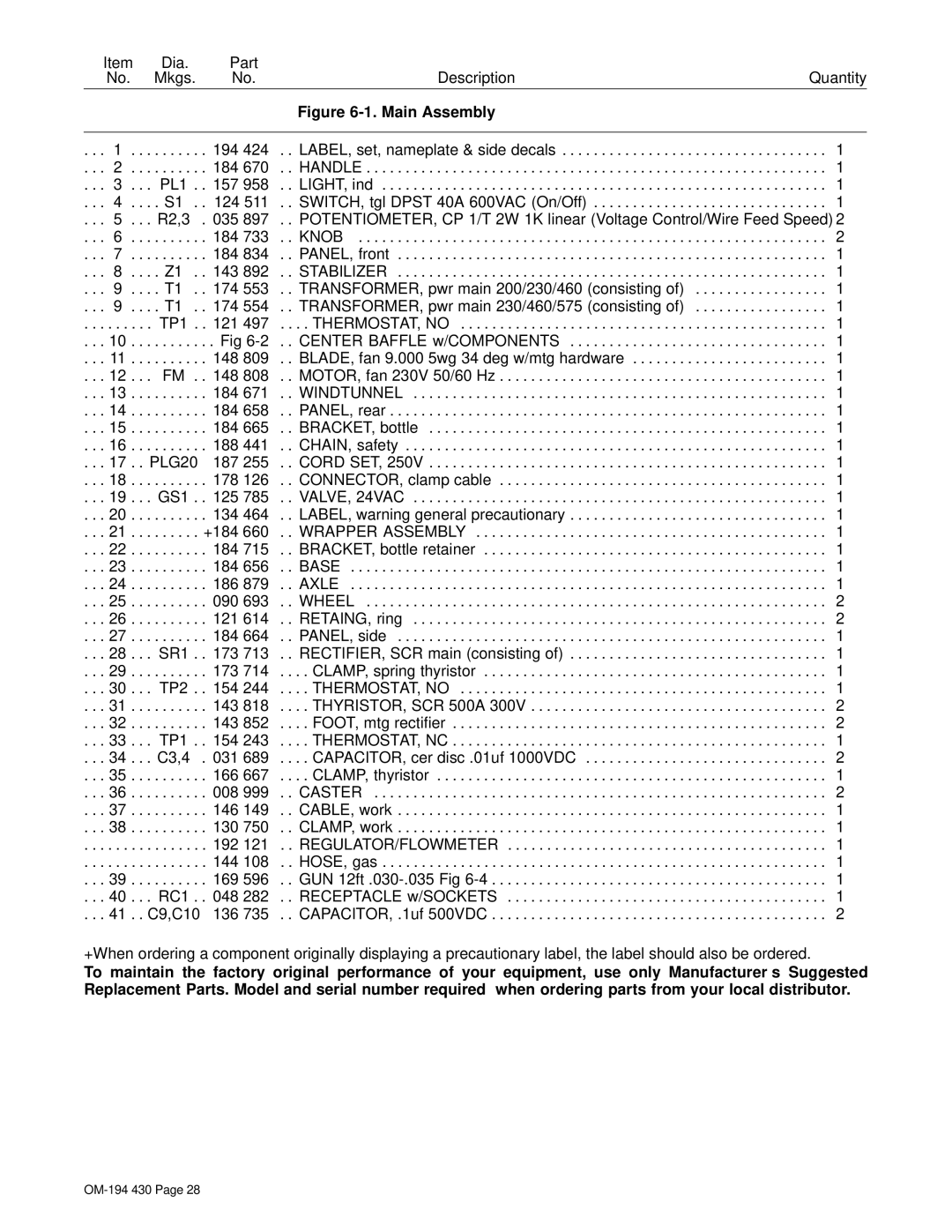

1Securing Screw

2Inlet Wire Guide

Loosen screw. Slide tip as close to drive rolls as possible without touch- ing. Tighten screw.

3

4Drive Roll

Install correct drive roll for wire size and type.

5 Drive Roll Securing Nut

Turn nut one click to secure drive roll.

|

|

|

| |

|

|

|

| |

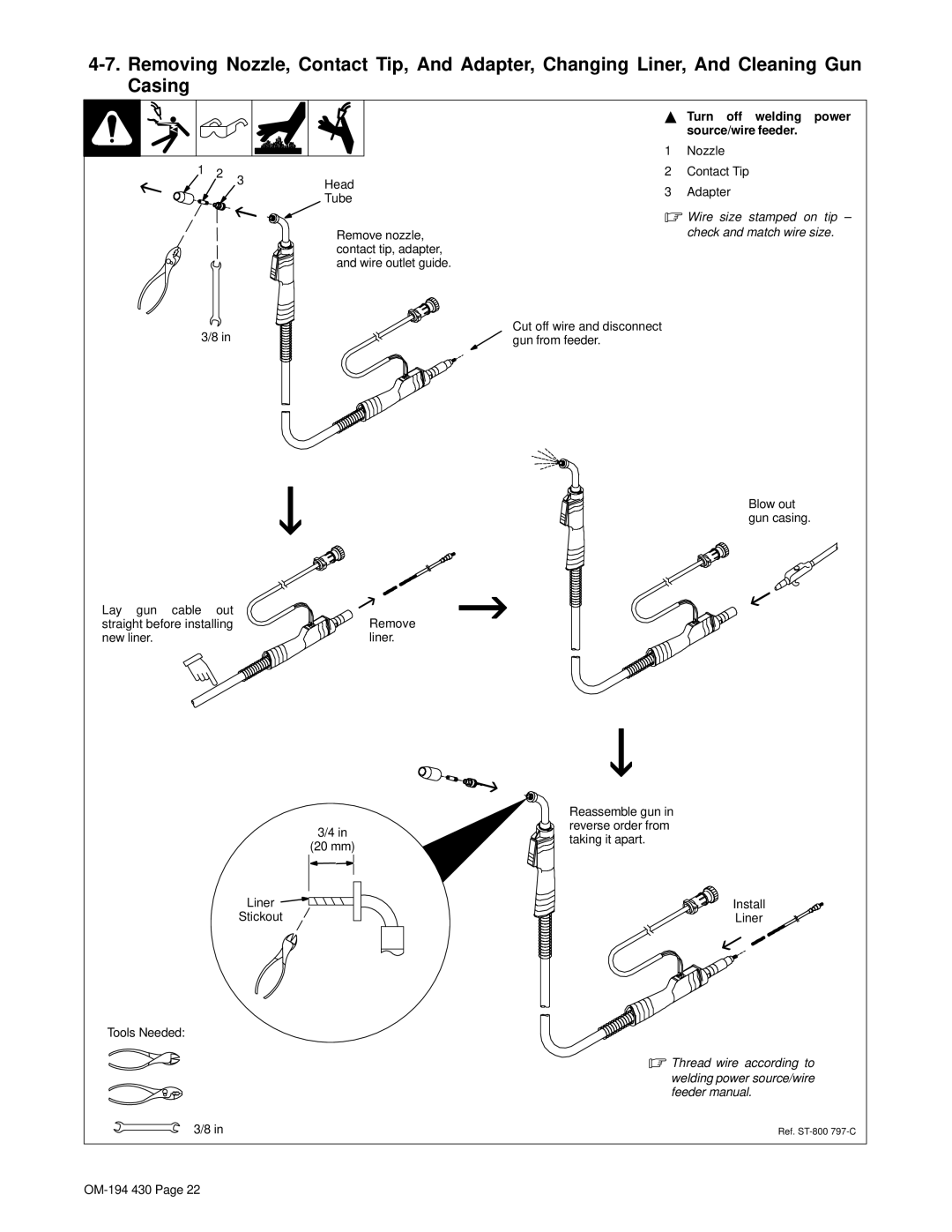

Correct |

| Incorrect | Y Turn Off power. | |

4 |

|

| ||

3 |

| View is from top of drive rolls look- | ||

2 |

|

| ing down with pressure assembly | |

|

| open. | ||

1 |

|

| ||

|

| 1 Drive Roll Securing Nut | ||

|

|

| ||

| 5 |

| 2 | Drive Roll |

|

|

| 3 | Wire Guide |

|

|

| 4 | Welding Wire |

|

|

| 5 | Drive Gear |

|

|

| Insert screwdriver, and turn screw | |

|

|

| in or out until drive roll groove lines | |

|

|

| up with wire guide. | |

Tools Needed: |

|

| Close pressure roll assembly. | |

|

|

|

| |

|

|

| Close door. | |

|

|

|

| Ref. |

|

|

|

|

|

|

|

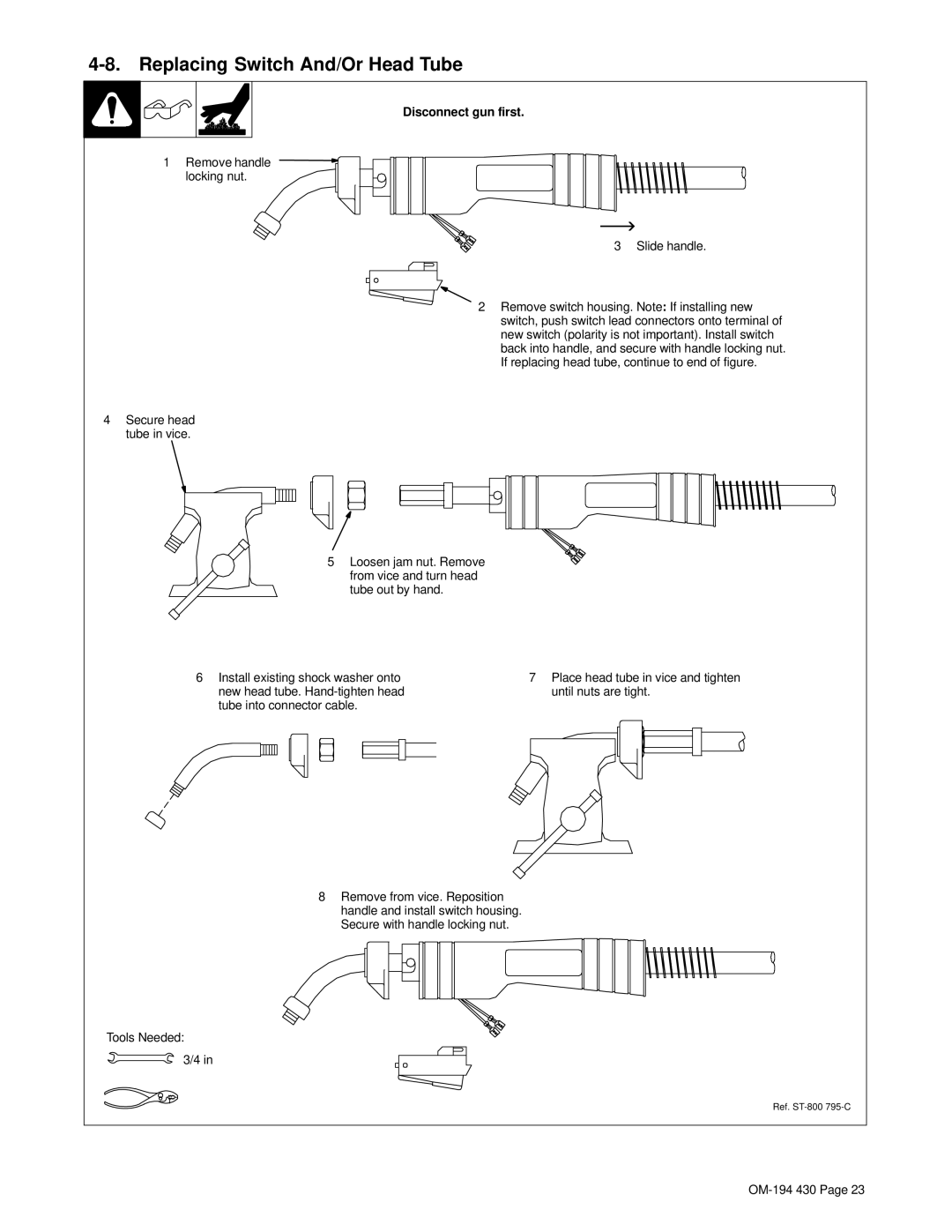

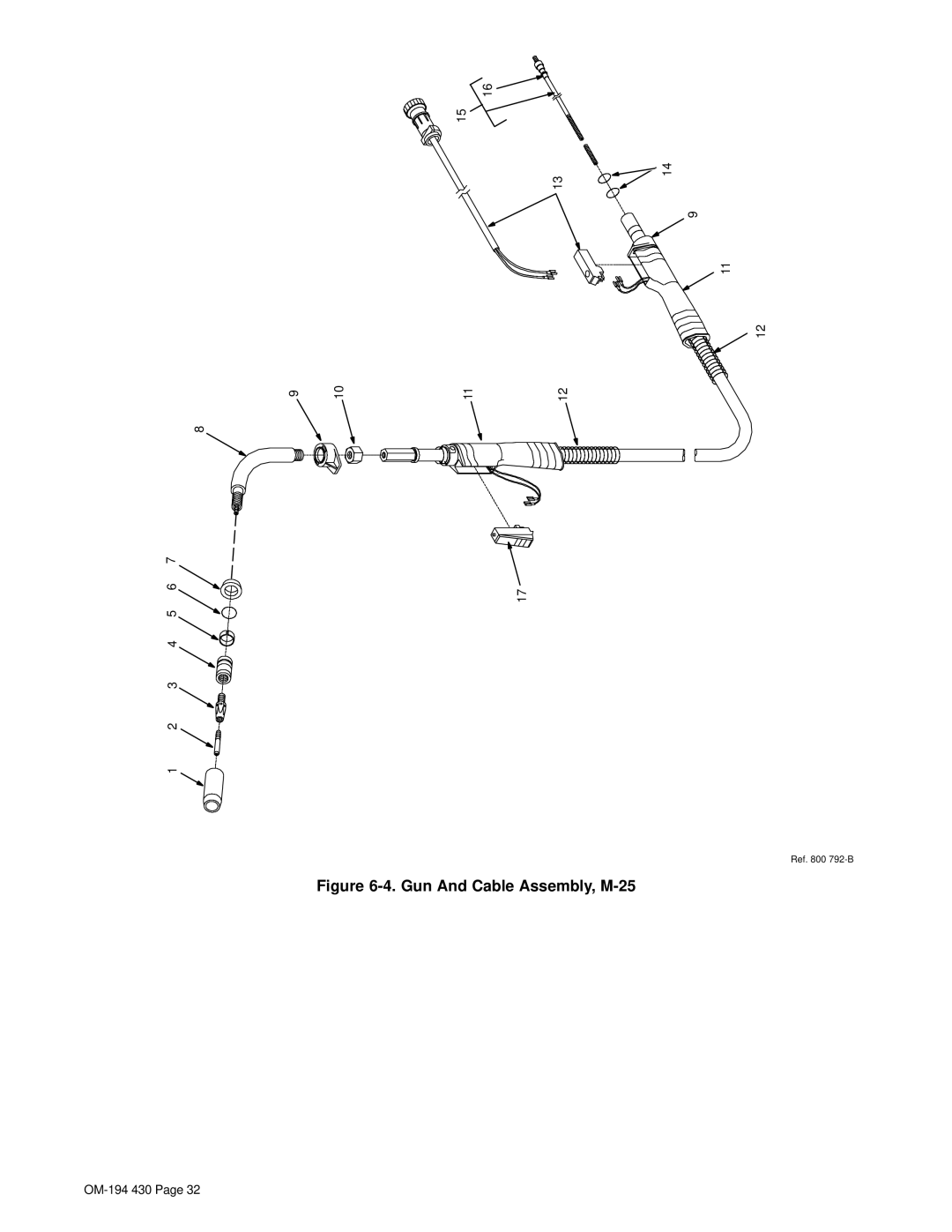

| Y Turn Off power before | |

|

|

|

| replacing contact tip. |

|

|

| 1 | Nozzle |

|

|

| 2 | Contact Tip |

|

|

| Cut off welding wire at contact tip. | |

|

|

| Remove nozzle. | |

Tools Needed: |

|

| Remove contact tip and install new | |

2 |

| contact tip. Reinstall nozzle. | ||

|

| |||

|

| 1 |

|

|

Ref. 800